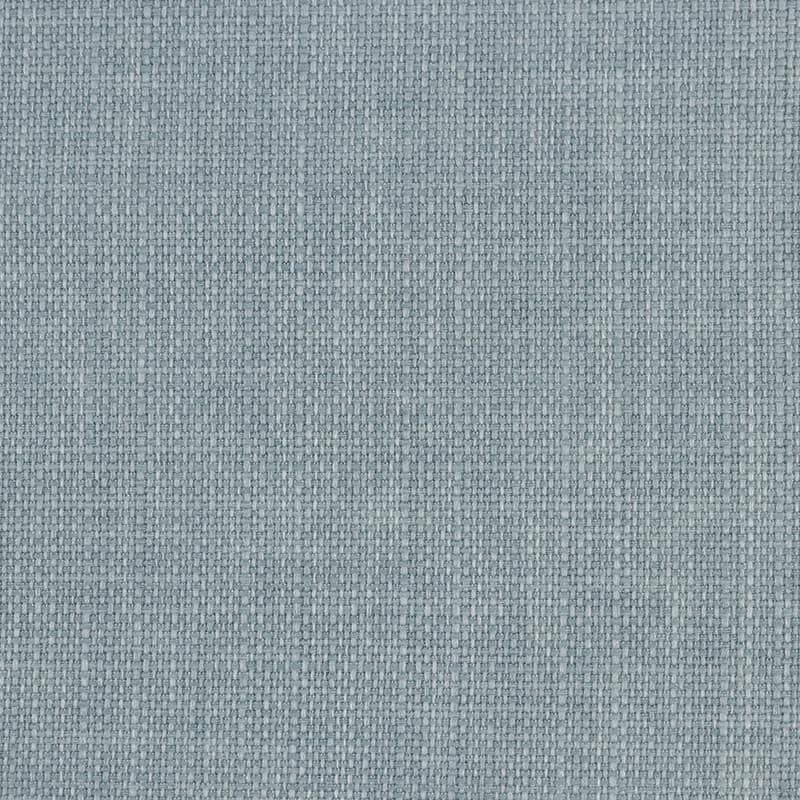

Plain weave fabric is the simplest and most common of the three fundamental textile weaves. People also know this fabric as ‘calico weave’ or ‘tabby weave’. It is a product of sliding each filler yarn over and under each warp yarn.

This weave dates back to ancient times. It has vertical and horizontal looms discovered in Asia, Africa, and Europe as early as 700 AD. It has existed since ancient times as both a technique and a fabric.

What is Plain Weave Fabric?

Plain weave refers to fabric varieties that all share the same weaving pattern. This is a classic weave that has horizontal (weft) threads passing over and under vertical (warp) yarns.

Plain weave fabrics are versatile, with no right or wrong side. They have a little stretch and are less prone to tearing. They fold readily and come in a variety of weights. They are also less absorbent than other weaves.

In textile production, there are two types of weaves: plain weave fabric and double weave fabric. Plain weave uses warp strands that alternate with weft yarns. But double weaving interlaces two sets of yarns.

Plain weave fabric is snag-resistant but wrinkles more. Meanwhile, the double-weave fabric is reversible with varied designs. People often use double weaves for heavy-duty applications such as upholstery.

Types of Plain Weave Fabric

Chiffon

Chiffon is a thin, airy, and sheer plain weave fabric. People can produce this from a variety of textiles, both synthetic and natural.

Flannel

This type has a loose weave. It is available in both plain and twill weaves. Manufacturers sometimes brush flannel on one or both sides. This helps lift fine fibers and make them feel even softer.

Organdy

This is a cotton plain weave fabric. It is fine and sheer. It is a lightweight material. So people use it in bridal gowns, evening gowns, drapes, and aprons.

Muslin

Muslin is a cotton fabric with a loose weave. People often use it in fashion prototypes. It is good for testing patterns before cutting and stitching.

Cheesecloth

Chefs use this fabric as a tool in the production of cheese. The loose weave of the fabric allows liquid to easily strain through it.

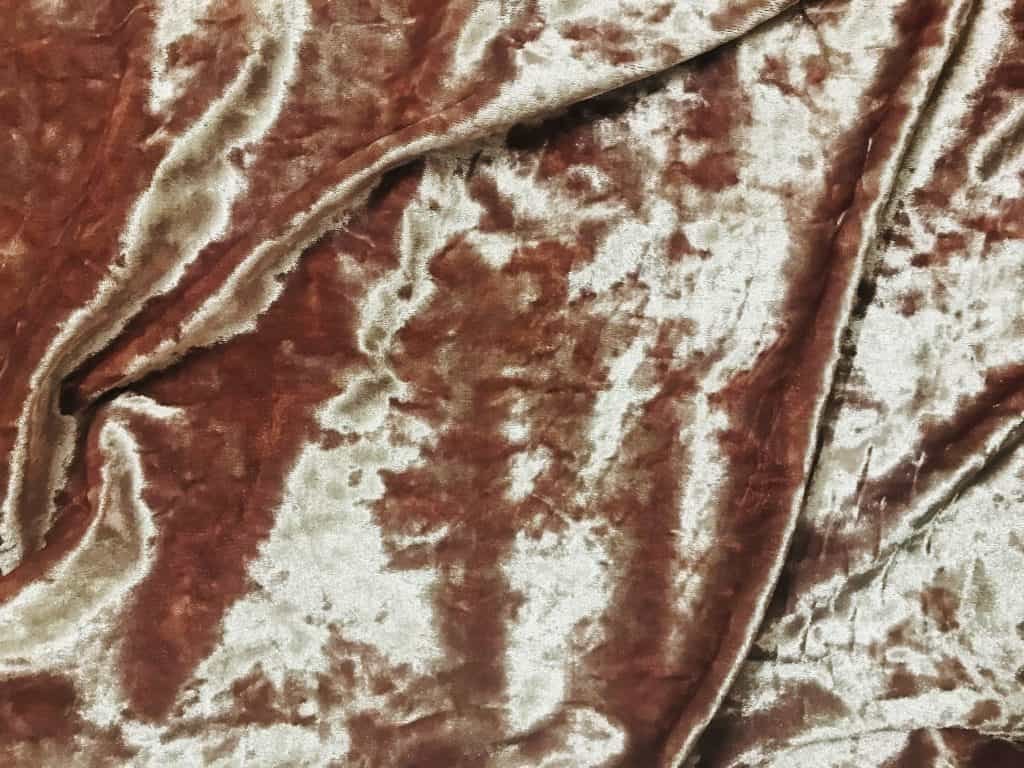

Velvet

Velvet comes from a special loom known as a double cloth. It makes two velvet pieces at the same time. This opulent fabric can be woven into any weave structure. It has an additional set of sheared warp threads for a smooth feel.

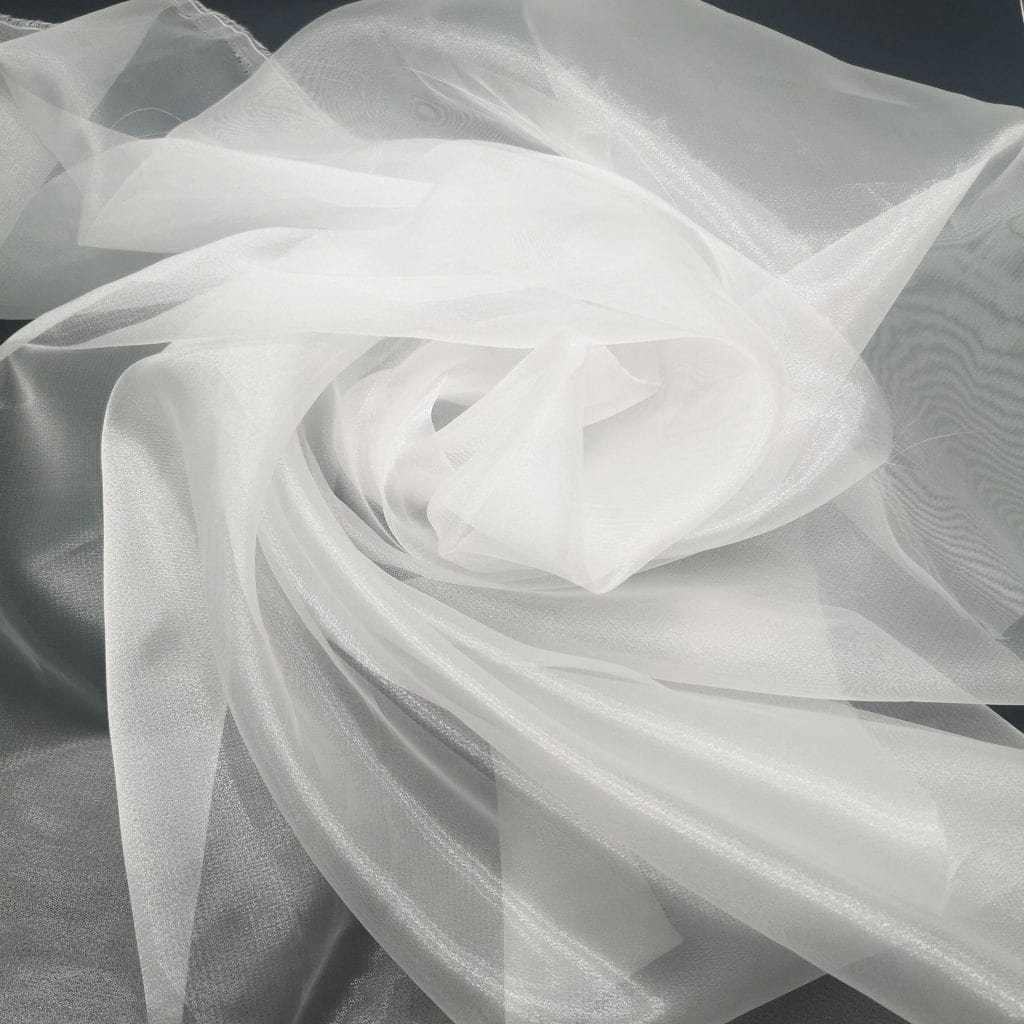

Organza

Organza is a lightweight, sheer, plain-woven fabric. People originally manufacture it from silk. But now synthetic fibers are also suitable for making this textile.

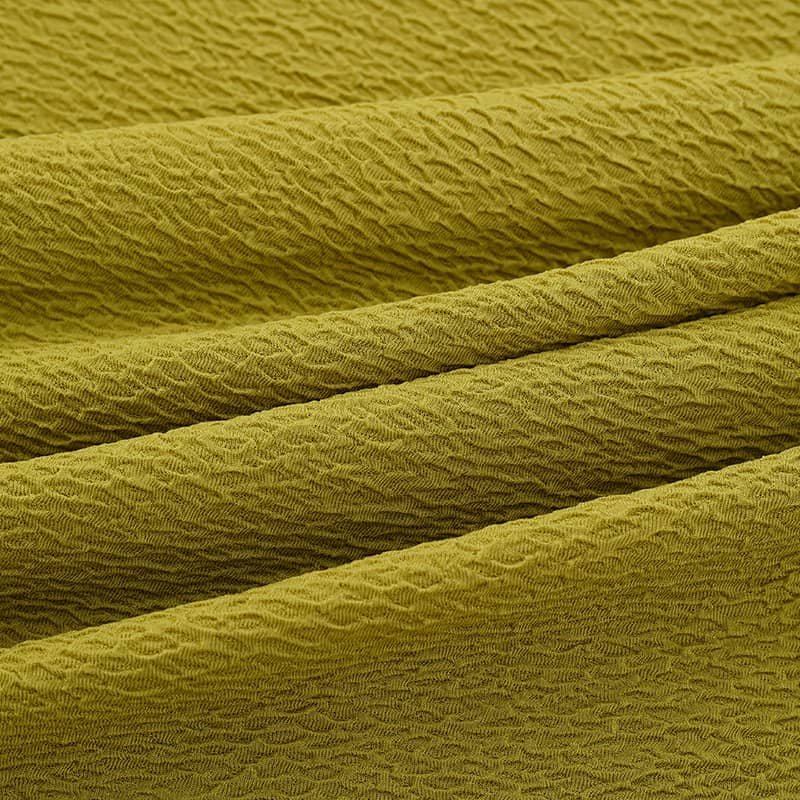

Georgette

Georgette is woven with tightly twisted s-twist and z-twist yarns. The yarns are twisted in opposite directions. These twists cause small puckers on the fabric’s surface. It gives the fabric its distinctive crinkled appearance.

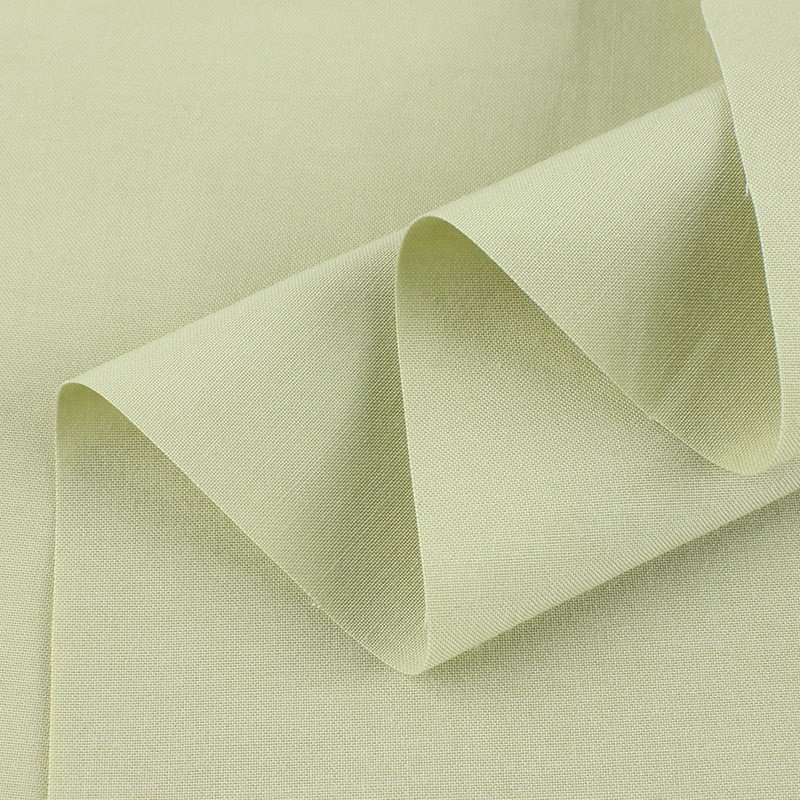

Poplin

Poplin has very fine warp yarns and coarser weft yarns. This fabric is lightweight. It has a light, airy drape.

Taffeta

Taffeta comes from the plain-weave technique. Manufacturers twist their threads to provide stiffness and structure.

Buckram

Buckram can either be on a tight or free weave. You can find this fabric inside baseball caps, stiff, and coarse cloth.

Cambric

This plain weave cloth has a smooth-finishing. Manufacturers flatten and roll it at high temperatures.

Crêpe

Any weave structure is suitable for producing crêpe. It has twisted or crimped threads. So its texture is rough and uneven.

Chambray

Chambray has indigo-dyed warp threads and an undyed weft. It gives the fabric a blue hue same as denim.

The Process of Making Plain Weave Fabric

- The process starts with warp preparation. Manufacturers prepare warp threads by coating them with a strengthening substance. Then, they wound onto a warm beam. They place the warp beam on the loom.

- The second stage is weft insertion. They insert the weft threads into the warp threads. They use a shuttle or a rapier to make this possible.

- Next, the manufacturers proceed to the shedding process. They create the shed through a series of raising and lowering heddles. This helps the weft threads to pass under the warp thread.

- Afterward, they will beat the weft thread into place using a beater. This step helps to make a tight weft thread. It creates a smooth and even fabric.

- They take up the fabric on a cloth beam as it is weaving. This is to ensure that the fabric is not stretched in the weaving process.

- They apply finishing treatments such as singeing, mercerizing, or bleaching. These treatments help in improving the softness and wrinkle resistance of the fabric.

Uses of Plain Weave Fabric

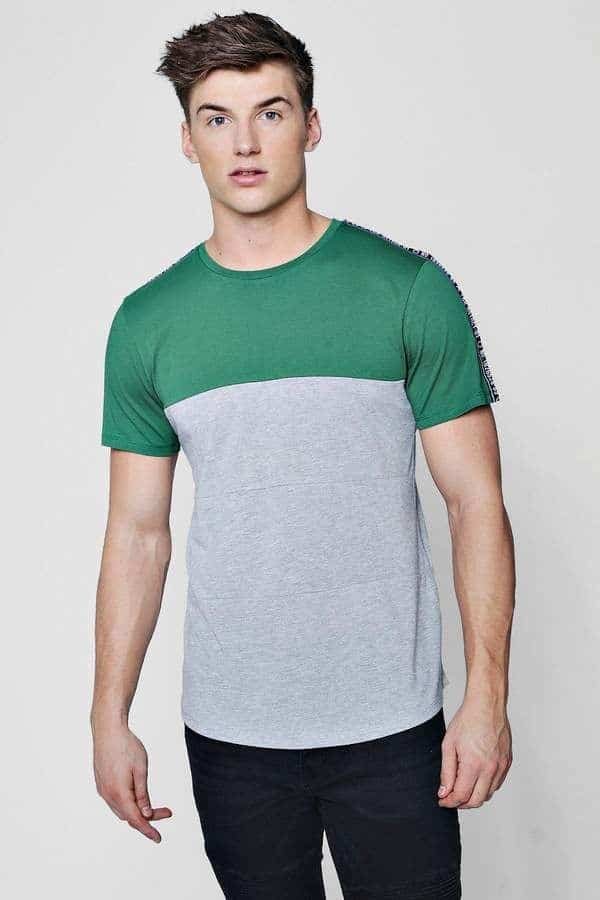

Clothing

Tailors, designers, and manufacturers use plain weave fabric to make clothing items. They make shirts, pants, skirts, suits, and dresses out of this fabric. They also use it for coats and jackets.

Accessories

You can also find bags, scarves, wallets, and other hair accessories that come from plain weave fabric.

Home Decor

This fabric serves its purpose in home decor. This includes making tablecloths, napkins, curtains, and bedspreads. They also use it for upholstery.

Industrial Fabrics

Manufacturers use plain weave fabric to produce filter clothes, tarpaulins, and conveyor belts. They also find this textile suitable for hard hats and fire hoses.

Other Uses

This fabric is so versatile. People also use it in making flags, banners, and kites.

Advantages and Disadvantages of Plain Weave Fabric

Plain weave is the firmest weave available. Both of its sides are the same, so it is reversible.

People recognize it as a “Balanced Weave” because of the even consistency of its surface pattern. It can also resist pilling and preserve its shape after washing.

However, plain weave wrinkles fast. It is necessary to iron them often to keep their smooth appearance. This fabric is also more expensive compared to knitted materials. It also has a lower thread count than other textiles.

Conclusion

Plain weave has existed since ancient times. It is the most common and simplest type of weave. It is firm, reversible, versatile, and less prone to tearing. But it also wrinkles easily.

Plain weave fabrics are durable and versatile, making them a staple in the fashion industry. They can showcase prints and patterns well but may wrinkle or shrink if not cared for properly.

Despite this, plain weave fabrics are sure to remain popular for years to come, whether used for apparel or accessories.

Despite its drawbacks, plain weave fabric has a bright future. There is the possibility of combining fibers and utilizing a new technology. Plain weave quality may improve over time. Its variety of applications will also expand.