Polybutylene terephthalate fabric, simply known as PBT, has distinct characteristics and various applications. Polyester is the parent material of PBT. This kind of fabric is known for its durability and resilience, making it suitable for outdoor environments.

PBT fabric was first created from the development of the original polyester, polyethylene terephthalate (PET). PET gained popularity in textile applications due to its strength, durability, and resistance to wrinkles and shrinking.

Researchers and engineers further explored polyester variations and created PBT fabric by polymerizing butylene glycol and terephthalic acid.

The fabric is proof of the constant pursuit of developing innovative materials that meet the needs of industries and consumers. Why is this fabric suitable for various applications beyond traditional polyester fabrics?

In this article, you will learn about PBT fabric’s properties, production process, applications, and advantages and disadvantages.

What Is PBT Fabric?

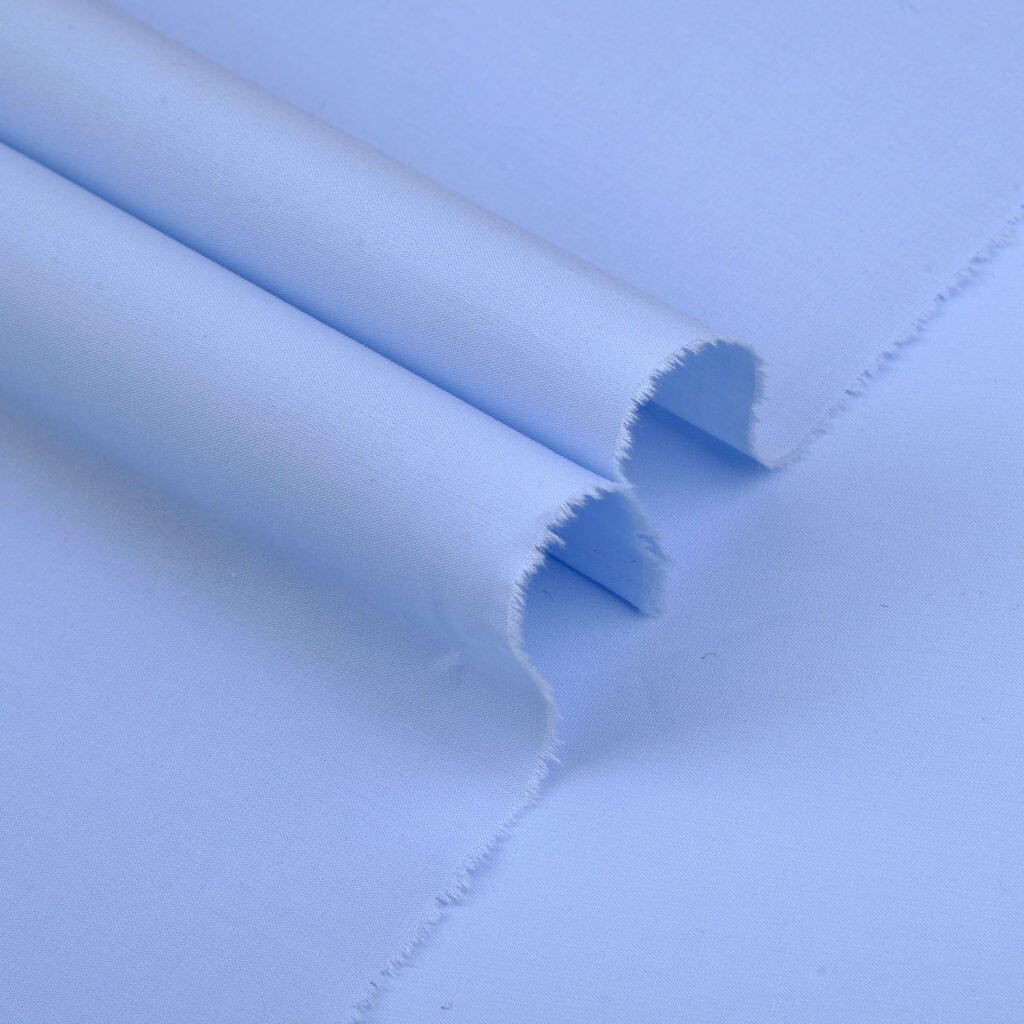

Polybutylene terephthalate fabric is a synthetic textile. It falls under polyester fabrics. The fabric shares similarities with other polyester variations, such as PET fabric.

PBT fabric has excellent resistance to abrasion, chemicals, and UV radiation. Thus, it is suitable for outdoor environments. It can withstand rigorous use and maintain its structural quality over time.

The fabric also has sustainable features. It can be produced using recycled materials. Thus, it reduces the negative environmental impact. Its durability and longevity also help minimize waste by extending the lifespan of products made from PBT fabric.

Properties of PBT Fabric

PBT fabric has several unique properties that make it a desirable material for various applications. Here are some key properties of PBT fabric:

Durability

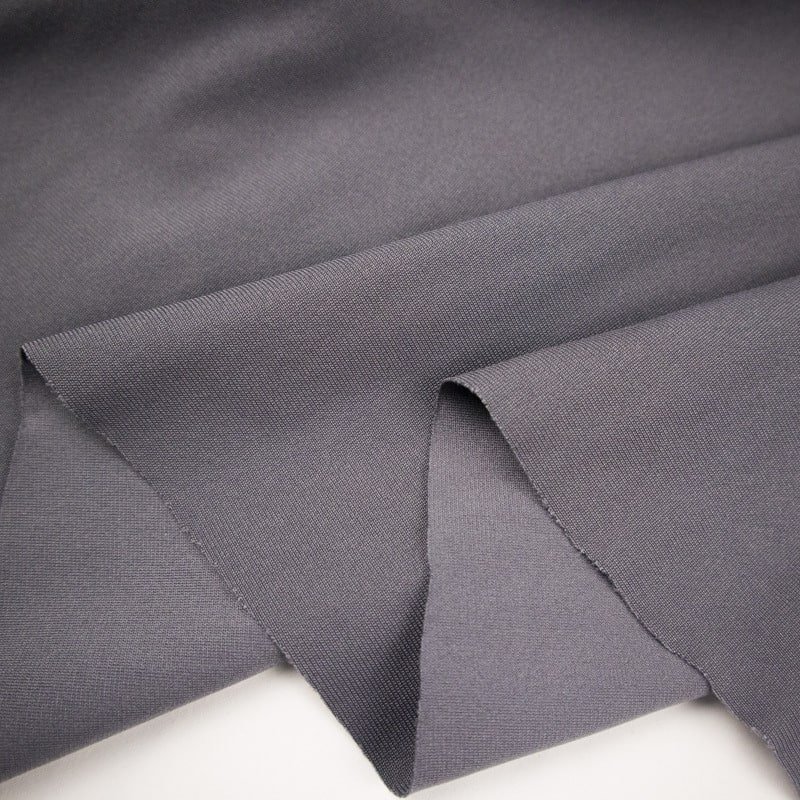

The fabric has excellent strength and durability. These properties allow the fabric to withstand rigorous use and maintain its shape over time. PBT fabric is also resistant to tearing, stretching, and abrasion. These enhance the fabric’s longevity.

Its durability also contributes to its ability to retain its shape and appearance even after repeated wear and washing. The fabric can bounce back to its original shape even after being deformed or compressed.

Chemical Resistance

PBT fabric has good resistance to chemicals, including acids, alkalis, and solvents. It is less prone to damage or degradation when exposed to various chemical substances. These enhance the fabric’s durability and lifespan.

Moisture Resistance

The fabric also has good resistance to moisture. This allows the fabric to absorb moisture from the body. This quality helps keep the wearer dry and comfortable during physical activities.

Heat Resistance

PBT fabric has heat resistance to a certain extent. But, it has a lower resistance compared to some other high-temperature resistant materials. The fabric can withstand moderate heat levels without melting or deforming. Thus, it is suitable where moderate heat exposure is expected.

Other Properties

PBT fabric has good resistance to ultraviolet (UV) radiation. It doesn’t easily degrade or fade when exposed to daylight. Thus, the fabric is a good option for outdoor applications requiring prolonged sun exposure. PBT fabric is also soft and comfortable.

How are PBT Fabrics Made

PBT fabric is made by polymerizing butylene glycol and terephthalic acid. These two materials go through a chemical reaction, forming polybutylene terephthalate. This is the polymer from which PBT fabric is made.

The polymer is first melted at high temperatures. Then, it is extruded through spinnerets to form continuous threads. The threads are then rapidly cooled to solidify the polymer and stabilize the fibers’ structure.

Texturing is then applied to introduce bulkiness and improve the fabric’s aesthetic and tactile properties.

Finishing processes may be applied to enhance performance and appearance. The textured threads can be further processed through weaving or knitting machines to create different fabric structures. Finally, post-treatments such as dyeing, printing, or coating may be applied to achieve the desired color, pattern, or functional properties of the fabric.

Applications of Polybutylene Terephthalate Fabric

PBT fabric has a broad range of applications due to its desirable properties. Its properties make it a popular choice in industries requiring durable fabric. Here are some common applications of PBT fabric:

Textile Industry

The fabric is used in producing various types of apparel like sportswear and activewear. It is usually used in swimwear and beachwear due to its chlorine resistance and colorfastness, even when exposed to harsh daylight and pool water.

PBT fabric is also used in lingerie and undergarments. Its softness and elasticity contribute to the comfort and fit of these garments.

Outdoor textiles like backpacks, tents, and outdoor furniture covers also have PBT. The fabric’s durability and ability to withstand harsh environmental conditions make it suitable for these outdoor applications.

Automotive Industry

PBT fabric is used in automotive interiors such as seat covers, door panels, and headliners. The fabric is used for seat covers in automobiles. Its durability, strength, and wear and tear resistance make it a good option for this.

Other Applications

The fabric can be found in upholstery, curtains, and decorative fabrics for home furnishings. Its durability and resistance to fading contribute to its suitability for household applications.

PBT fabric is also used in medical applications such as wound dressings, surgical gowns, and bandages. Its strength, softness, and moisture management properties make it suitable for healthcare settings.

Advantages and Disadvantages of Polybutylene Terephthalate Fabric

Advantages

- Long-lasting and resistant to tearing or stretching

- Good resistance to chemicals

- Resistant to damage caused by UV radiation

- Good moisture management capabilities

- Soft and comfortable

- Versatile

- Sustainable

Disadvantages

- Sensitive to high temperatures

- Limited color fastness

- Prone to the formation of small fabric balls or fuzz on the surface

- Relatively higher production cost

Conclusion

Polybutylene terephthalate (PBT) fabric is a durable and lightweight material that is ideal for fashion applications. It is resistant to wear and tear as well as chemicals and UV light.

PBT fabric is easy to care for and can be machine washed and dried. Its potential for sustainability further enhances its appeal. Thus, it is a promising choice for environmentally conscious consumers.

Overall, PBT fabric is a great choice for designers looking for a strong and reliable fabric that can withstand the rigors of fashion.