How To Decide Which T-shirt Printing Method Is Best?

Determining the ideal t-shirt printing technique requires analyzing order specifications, fabric compatibility, and design complexity. For bulk orders exceeding 500 units, screen printing delivers cost efficiency and vibrant color saturation. Each method demands specialized equipment—industrial-grade machinery for high-volume runs versus craft tools for prototypes. Fabric composition critically influences outcomes; polyester responds better to dye sublimation while cotton excels with direct-to-garment (DTG) printing. Setup complexity also varies: techniques like heat transfer vinyl suit small batches with minimal tooling, whereas discharge printing necessitates advanced chemical handling. For brands prioritizing rapid turnaround, Ludyway recommends aligning technique selection with production timelines and custom t-shirt manufacturer capabilities.

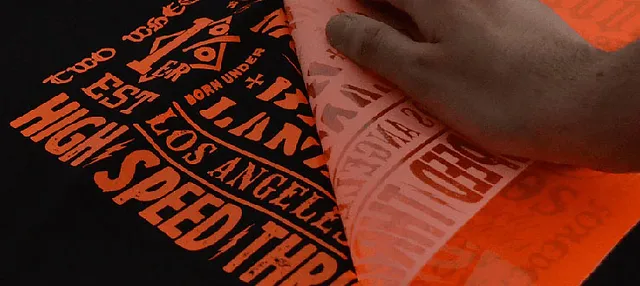

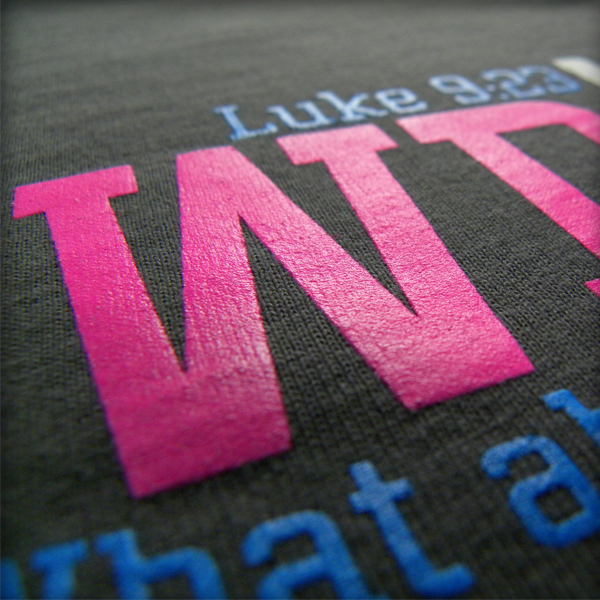

Screen Printing

This industry-standard method utilizes nylon mesh stencils to deposit ink through design apertures onto garments. The process achieves exceptional color opacity and durability, making it ideal for corporate uniforms and promotional apparel.

Equipment required: Exposure units, emulsion-coated screens, pneumatic presses, and conveyor dryers.

Precision alignment ensures accurate design placement across thousands of garments. Thick ink layers create tactile impressions that withstand repeated industrial laundering. While multicolor designs require separate screens and expert color registration, the method supports specialty inks like metallics and foils. Ludyway’s screen printing services accommodate orders from 50 to 50,000+ units with Pantone-matched color accuracy.

Pros

- Superior opacity on dark fabrics; production speeds exceeding 450 units/hour

- Wide textile compatibility including cotton, polyester, and blends

- Cost efficiency for bulk orders above 500 pieces

Cons

- High setup costs for multicolor designs

- Limited detail reproduction below 4pt fonts

- Minimum order quantities for profitability

Dye Sublimation Printing

This digital method infuses designs into polymer-based fabrics using heat-activated dyes. The gasified ink permeates textile fibers, resulting in permanent, crack-resistant graphics ideal for all-over prints.

Tools required: Sublimation printers, heat presses, and coated transfer papers.

The 400°F heating process opens fabric pores for dye infusion, with designs becoming integral to the material. Best suited for custom sports clothing manufacturer applications, it delivers stretch-compatible graphics without compromising moisture-wicking properties. Note: Natural fibers like cotton cannot withstand required temperatures.

Pros

- Seamless edge-to-edge printing capabilities

- No texture buildup or hand-feel alteration

- Exceptional color vibrancy and wash fastness

Cons

- Exclusive compatibility with polyester substrates

- Inapplicable to dark-colored garments

Direct-to-Garment (DTG) Printing

DTG technology applies water-based inks directly onto textiles using modified inkjet systems, enabling photographic detail reproduction without screen setups.

Equipment required: Textile-primed inkjet printers and curing systems.

The process excels with complex designs exceeding 10 colors, achieving 1440dpi resolution. Pretreatment solutions ensure optimal ink absorption on cotton, while specialized machines handle polyester blends. Ideal for custom hoodie manufacturer projects requiring distressed effects or tonal gradients.

Pros

- Zero setup fees for design changes

- Eco-friendly water-based ink systems

- 1-piece minimum order feasibility

Cons

- Higher per-unit costs versus screen printing

- Reduced opacity on polyester blends

Heat Transfer Vinyl (HTV)

This technique uses pressure-cut vinyl films heat-bonded to garments. Multiple varieties include glitter, flocked, and thermochromic options for dimensional effects.

Equipment required: Digital cutting plotters and heat presses.

Industrial cutting systems handle intricate patterns, while manual applications suit prototypes. The raised texture provides premium tactile appeal for logo-centric designs. Ludyway’s sublimation printing services complement HTV for hybrid decoration techniques.

Pros

- Durable metallic/reflective finishes

- Low equipment investment for sampling

Cons

- Labor-intensive weeding process

- Reduced elasticity on performancewear

Plastisol Transfers

Screen-printed designs are first applied to release paper, then heat-transferred to garments. This hybrid approach combines screen printing’s vibrancy with simplified application.

Required tools: Transfer presses and pre-printed plastisol sheets.

The method eliminates multicolor registration challenges during final production. Transfers remain stable for months, enabling distributed manufacturing. Particularly effective for custom uniform manufacturer programs requiring global fulfillment.

Pros

- Consistent color matching across production runs

- Reduced equipment footprint at point of application

Cons

- Additional material costs for transfer sheets

- Potential cracking on high-stretch areas

Selecting a T-Shirt Printing Method: Technical Considerations

Evaluate these parameters when specifying decoration methods:

Fabric Compatibility Matrix

| Technique | Cotton | Polyester | Blends |

|---|---|---|---|

| Screen Printing | Excellent | Good | Excellent |

| Dye Sublimation | Unsuitable | Excellent | Limited |

| DTG | Excellent | Moderate | Good |

Cost-Performance Analysis

Screen printing dominates economies of scale above 300 units (cost reduction up to 60% vs DTG). For rush orders under 50 pieces, HTV or DTG delivers faster ROI. Ludyway’s production experts optimize technique selection based on quantity, timeline, and quality benchmarks—contact info@ludyway.com for technical consultations.

FAQs

Which Printing Technique Offers Maximum Durability?

Screen-printed plastisol withstands 50+ industrial washes, making it optimal for workwear. Sublimation ranks second with colorfastness exceeding 40 washes.

How Do I Choose Methods For Blended Fabrics?

For 50/50 cotton-poly blends, discharge-modified plastisol or specialty DTG pretreatments prevent cracking. Testing is essential—request swatches from your manufacturer.

Conclusion

Mastering these eight techniques empowers brands to align decoration methods with product requirements. For technical specifications or bulk production quotes, partner with Ludyway—specialists in scalable, quality-focused apparel manufacturing since 2018.