A comprehensive technical package (tech pack) serves as the foundational document bridging design vision and manufacturing execution. Unlike conceptual sketches, a professionally engineered tech pack translates creative intent into quantifiable specifications, enabling precise cost estimation, consistent quality control, and efficient production scaling. This definitive guide outlines the industrial standards and technical frameworks required for developing manufacturing-ready documentation.

Technical Specifications: Definition and Critical Function

A tech pack functions as the engineered blueprint for garment production, containing all technical parameters required for manufacturing. Essential components include:

- Material Specifications: Fiber content, weight (GSM), finish, and compliance certifications

- Construction Details: Stitch types (ISO 4915/4916), seam allowances, and reinforcement methods

- Measurement Protocols: ASTM D6192/D6962 standard tolerances (±3mm critical points)

Ludyway’s production data indicates brands utilizing ISO-compliant tech packs achieve 92% first-sample approval rates versus 47% with basic specifications. This documentation enables accurate cost analysis, MOQ determination, and quality benchmarking.

Industrial-Grade Tech Pack Components

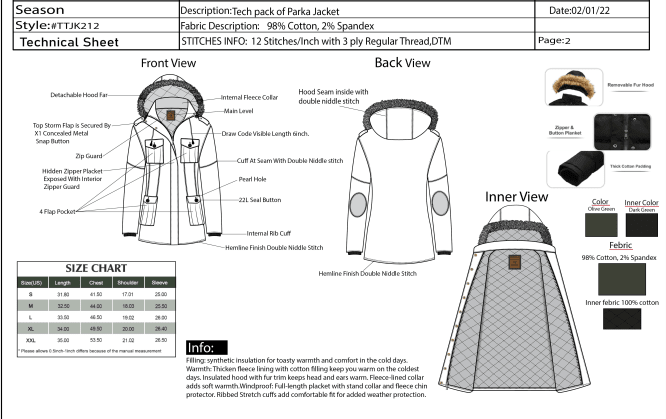

- Technical Flats and Construction Details

Develop vector-based technical flats using CAD software (Adobe Illustrator or Tukatech), including:

- Orthographic views (front, back, side) with 1:5 scale

- Seam callouts (French, flat-fell, superimposed)

- Stitch density indicators (12-14 SPI for seams)

- Hardware placement coordinates (±2mm tolerance)

Include material specifications:

- Fiber content percentages (e.g., 98% cotton/2% elastane)

- Weight: 180-220 GSM for knits

- Finish: Enzyme wash, peach skin

- Compliance: Oeko-Tex Standard 100, REACH

For decorated garments, reference screen printing specifications or sublimation printing parameters where applicable.

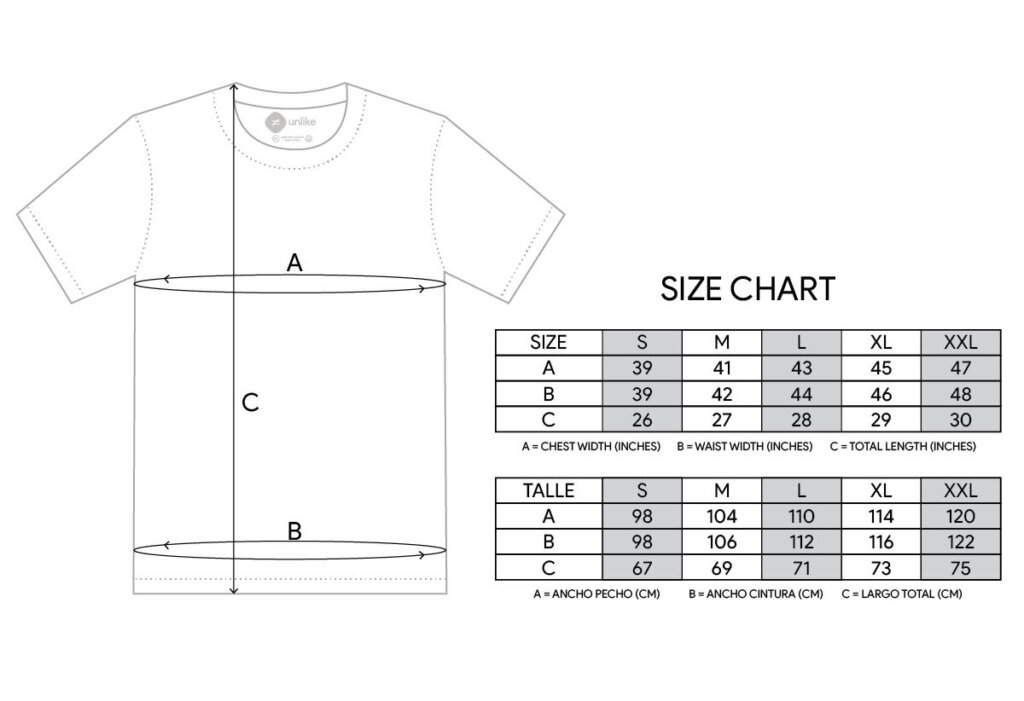

- Graded Measurement Specifications

Implement industry-standard grading rules:

| Measurement Point | Grade Rule (cm) | Tolerance |

|---|---|---|

| Chest/Bust | 5cm between sizes | ±1.5cm |

| Waist | 4cm | ±1cm |

| Hip | 5cm | ±1.5cm |

| Sleeve Length | 1.5cm | ±0.5cm |

Include 3D virtual fit analysis data and stress-test results for performance wear. Ludyway’s custom cut and sew manufacturing requires grade rule charts with 28+ measurement points.

- Construction Blueprints

Provide exploded technical drawings detailing:

- Seam cross-sections (4-thread overlock vs. safety stitch)

- Reinforcement zones (bartack density: 18-22 stitches/cm²)

- Hardware installation diagrams (rivet placement ±1mm)

- Lining attachment methods (bonded vs. stitched)

Specify machine settings: Needle size (Nm 70-90), thread tension (400-450 cN).

- Component Specification Sheets

Document all non-fabric components:

- Zippers (YKK® #3-5, tape composition)

- Buttons (diameter, shank height, material)

- Labels (woven satin vs. printed polyester)

- Embroidery details (stitch density, backing material)

Include approved supplier lists and material safety data sheets.

- Color Standardization

Implement digital color management:

| Color Application | Standard | Delta E Tolerance |

|---|---|---|

| Fabric Dyeing | Pantone TPX | ≤0.8 |

| Printing | Pantone TCX | ≤1.2 |

| Thread | Pantone Solid | ≤1.5 |

Include spectrophotometer readings (L*a*b* values) and approved strike-offs.

- Labeling and Compliance Markings

Detail legal requirements:

- Care symbols (ISO 3758:2012)

- Fiber content (US FTC 16 CFR 303, EU 1007/2011)

- Country of origin (19 U.S.C. §1304)

- Flammability compliance (16 CFR 1610)

Specify placement coordinates (±3mm) and attachment methods.

- Material Placement Diagrams

Include marker making diagrams showing:

- Fabric utilization efficiency (85% minimum)

- Directional nap/grain alignment indicators

- Pattern matching requirements (±1.5mm tolerance)

- Cutting layouts for various widths (44″/58″)

- Bill of Materials (BOM)

Structure BOM with:

| Component | Specification | Supplier Code | Unit Cost |

|---|---|---|---|

| Main Fabric | 98% Cotton 2% Spandex, 220GSM | LWD-CT220 | $4.25/m |

| Interlining | Polyester fusible, 80GSM | LWD-PF80 | $0.85/m |

| Zipper | YKK #5 Vislon, 65cm | LWD-ZV65 | $1.20/unit |

Include wastage factors (8-12%) and alternative approved materials.

Quality Assurance Protocols

Incorporate manufacturing oversight systems:

- In-Process Checks: 7-stage verification points

- AQL Sampling: ANSI/ASQ Z1.4 Level II

- Testing Parameters:

- Colorfastness (ISO 105-C06: 4+ after 20 washes)

- Seam slippage (ISO 13936-1: >100N)

- Dimensional stability (ISO 5077: ±2%)

- Measurement Verification: 32-point checklist

Ludyway’s private label clothing program requires tech packs with embedded QC protocols to ensure batch consistency.

Digital Workflow Integration

Implement PLM (Product Lifecycle Management) systems for:

- Version control with audit trails

- Automated BOM generation

- Real-time collaboration portals

- Integration with 3D prototyping (CLO, Browzwear)

Cloud-based platforms reduce development cycles by 40% while maintaining ISO 9001 documentation standards. Ludyway’s technical team emphasizes digital twin implementation for virtual fit validation before physical sampling.

Conclusion

A comprehensive tech pack transforms design concepts into manufacturable specifications through precise technical documentation. By implementing standardized measurement systems, material specifications, and quality control protocols, brands ensure production accuracy and consistency. The industrial-grade framework outlined above—incorporating ASTM/ISO standards, digital workflow integration, and embedded QC systems—reduces sampling iterations by 65% while ensuring manufacturing precision from prototype to bulk production.