Ever wonder how different types of shirt printing are done? It is easy to transform a basic t-shirt into one that expresses your personality. You can alter the printing process to meet your demands for both personal and professional use.

Screen printing, direct-to-garment printing, dye-sublimation, heat press printing, and heat transferable vinyl are some of the most well-liked techniques for types of printing on shirts. There are different types of printing on shirts with images, though these are the ones that predominate in the industry. Small-scale printing applications benefit from methods including vinyl cutouts, heat transfers, and stenciling. Indirect screen printing, discharge printing, and airbrushing are further alternatives.

Your brand and the preferences of your clients will influence the designs you decide to print. You must choose the different type of shirt printing method that best suits your business and target audience from among the various possibilities available.

How To Decide Which T-shirt Printing Method Is Best?

What is the best way to print t-shirts? Many T-shirt printing methods exist because they serve various purposes, but if we had to choose only one if we were seeking a speedy response, we’d say go with screen printing (for large orders).

Every technique demands particular tools and materials. Some require high-end commercial technology, whilst others can function with simple craft supplies. This implies that some printing processes could have a significant initial investment.

Another thing to bear in mind is that some techniques favor particular fabric kinds over others, like cotton over polyester.

Finally, certain printing techniques are effective for printing just one or two shirts, while others involve so much setup time that you will get a much higher return on your investment if you can print huge quantities of shirts at once.

Check out this summary of how each t-shirt printing types function!

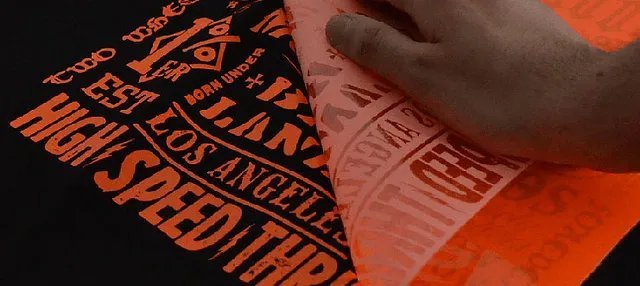

Screen Printing

One of the most popular ways to make T-shirts is with this technique. If you’re not familiar, you’ll need a stencil and nylon mesh to achieve this.

Equipment required: dryer, exposure unit, screens, and presses.

You may t-shirt design placement guide where it needs to be since the mesh holds the stencil in place. The location where the ink will be applied to the cloth is in the design’s empty spaces.

The ink is then applied to the screen, allowing the screen to be used to apply the ink to the shirt in the correct locations.

The ability to produce outcomes that are high-quality and reliable is screen printing’s key advantage. The print on a beloved T-shirt you possess was likely screen printed.

This technique is also excellent for mass production, making it a practical choice for those who must produce a big number of shirts in a short amount of time.

Many people think that only a few colors may be used in screen printing to create designs. The fact is that you can achieve colorful and intricate designs with screen printing, but you’ll need a lot of technical know-how, experience with artwork separations, and halftones.

Pros

- Versatility with a variety of textiles, vibrant, rich colors that are of good quality due to the thick ink, speed (4500+ items per hour for one design)

- A large variety of color schemes for various effects

- Profitable if you deal with big-batch orders.

Cons

- Lengthy design preparation and customization process

- Inefficiency for intricate illustrations and lifelike photographs

- Difficulties applying multi-color illustrations

- Low profitability for small runs

- Restriction on where images may be placed on the surface.

Dye Sublimation Printing

You will require a unique kind of dye to employ dye sublimation printing. When it comes into touch with the fabric, this liquid dries quite quickly.

Tools required: a sublimation printer, inks, release paper, and a heat press.

You must next use heat and pressure to permanently transfer the design to the shirt.

Liquid starts to transform into gas when heated, and the cloth starts to expand as well. The petrol then penetrates the freshly created spaces in the fabric.

After the heat is gone, the cloth shrinks, trapping the gas molecules inside the shirt.

This procedure is not appropriate for cotton T-shirt manufacturers since it applies heat directly to the fabric. When using polyester, works best.

Pros

- Unlimited colors are possible when utilizing the screen and HTV technologies

- Long-lasting designs that won’t flake or fade

- The best option for continuous solutions

Cons

- Partial dyeing (folds, side seams); useless on dark textiles

- Only produces good results on polyester

Belt Printing

A belt printer transports t-shirts to stations along a straight line using a large belt. Unlike a circular machine that transports t-shirts on little tables to print heads, it pauses them before lowering print heads to start printing.

Many people refer to this as “Belt Printing” since historically, screen prints have been created using what is known as “a belt printer.” Belt printers are gigantic printers that imprint clothes on colossal screens. a continuous belt that moves to clothes, typically t-shirts, for this procedure. Even if there are still many belt printers in use today, they would be classed as ancient technology.

The function of belt printers has been assumed by large table printers. Instead of a continuous belt, there are moving tables. The product’s movement pattern has changed, even though screen sizes remain unchanged.

In terms of creativity, there are no limitations. Unique patterns covering entire types of clothing prints will let your personality shine through. Belt printing typically entails artwork that extends the seams and, on rare occasions, also features the sleeves, hem, collar, or all of them. The thing appears to be entirely coated in this way.

To give the procedure a smooth feel, water-based ink is used. Even though it’s only a one-color print, you can combine it with other colors when printing. Your apparel will have a particular retail look as a result of the process. Each piece of clothing has a unique finish thanks to the complete screen. Belt prints frequently occur in the folds and creases; although this may seem unfinished, it is not.

Pros

- Lighter

- Cheaper

- Easily movable ground

Cons

- Consistency of designs and speed is low

- Printing different colors registration

DTG Printing

This is one of the best choices for producing a huge quantity of top-notch T-shirts at once, provided that you have the money to buy a DTG printer. As the name implies, you can print ink directly into the fabric with this kind of printer.

Equipment required: Heat press and DTG printer

When it comes to the designs you can make, your options are essentially endless. This is as a result of the fact that you may work with design programs like Photoshop to produce the ideal image for your T-shirt.

Once the image from your computer has been uploaded, you may use the DTG printer to print the design onto your shirt.

Since highly intricate designs can be incorporated, DTG printing is the finest option. It’s important to remember that if you want the desired outcomes, you must utilize a high-quality printer.

The overall resolution of the printed image can suffer if you don’t. Moreover, it is advised to always hand wash DTG shirts in cool water and hang dry them.

The image will fade considerably more quickly if you wash them in hotter water or dry them in the dryer.

Pros

- Being able to produce distinctive effects (gloss, smooth gradients)

- Resistance to wear: the pattern can withstand more than 60 washes

- Flexibility to alter layout for various copies; greatest detail; silk screen printing can’t match it

- Water-based eco-friendly ink

Cons

- Significant investments are necessary due to the expensive cost of a textile printer

- Only cotton materials produce decent results

- There is a chance that they will fade over time, and posting picture restrictions

Plastisol Printing

Today’s t-shirt designers are becoming more and more adept at using plastisol or indirect screen printing. Using the same kind of plastisol inks used in screen printing, this technique incorporates certain screen printing fundamentals. The primary distinction is that the ink is applied to a plastisol transfer sheet as opposed to the fabric directly.

Required tools: Heat press and transfer sheets

To produce a long-lasting, raised design on the fabric’s surface, the transfer sheet is next heat pressed onto the t-shirt.

A third party can simply mass-produce the design on plastisol sheets using the digital design that some designers create to save money. Following that, the plastisol sheet is heated and adhered to a shirt by the artist.

Pros

- High-quality, long-lasting designs are the advantages of this approach.

- Also, compared to conventional screen printing, there will be a lot less mess and setup time.

- You only need to execute the digital graphic design and have a heat press on hand to finish the shirt if you outsource the plastisol transfer sheet printing!

Cons

- Plastisol transfers can be tough to apply, which is one of this method’s drawbacks

- If done incorrectly, the designs will subsequently peel and crack

- Moreover, this approach performs admirably for small orders but is less effective for large ones

Heat Transfer Vinyl Printing

One of the most common ways that both professionals and amateur decorators decorate shirts is with heat transfer vinyl. A unique kind of vinyl known as HTV vinyl has one decorative side and one side that is coated in a heat-activated adhesive. You may use a vinyl cutting tool to create intricate designs, logos, and writing, which you can then heat seal onto fabric.

Equipment required: Heat press, squeegee, Cricut maker

Although it’s not technically “printing,” many artists utilize vinyl to produce raised, long-lasting images on t-shirts in place of ink. The production of vinyl designs will likely be carried out by large-scale professional operations using gigantic commercial cutting equipment. The fact that you can also create your vinyl cut-outs using a basic electronic cutting device like a Cricut, meanwhile, is another reason why at-home artists adore this technique.

Glitter vinyl, flocked or velvety vinyl, and metallic vinyl are just a few varieties of the basic plasticky vinyl you can utilize.

You have a lot of versatility when using Heat Transfer Vinyl for small orders or even just for usage at home. All you need is a cutting machine and an iron to get started making t-shirts for your child’s basketball team! Nothing more than a Cricut and a heat press are all you need to get a small business off the ground.

Pros

- Making an HTV design typically requires less time and effort than many other approaches, in addition to having a low start-up cost.

- Moreover, HTV designs outlast nearly all printed designs in terms of endurance.

Cons

- The disadvantage of employing HTV is that you have to cut out the HTV numerous times for each garment, which makes it ineffective for big orders.

- Moreover, since a heat press is required to activate the vinyl’s adhesive, using HTV on a heat-sensitive cloth is not an option.

Heat Press Printing

Heat press printing is a suitable choice for a novice or at-home artist, while it frequently does not offer the high quality of certain other techniques. Despite this, some experts or small-business owners successfully sell shirts with thermal press printing.

Equipment required: Cover Sheets, Vinyl Cutter, and Thermo Tape.

An inkjet or laser printer is used to produce a design from a computer for heat press printing. The only paper that can be printed on is iron-on transfer paper. The design is then ironed or heat-pressed onto your shirt.

Because of its simple setup and minimal initial investment, this technology is ideal for at-home designers. You may make intricate designs or images using it just as easily as you would on paper. If you want to make unique artwork, you’ll need to learn how to utilize graphic design tools, but you can also just use pictures you discover online or photos you took with your phone!

Heat press printing, however, might not last as long as screen printing or HTV designs. Also, it frequently fails on dark-colored shirts since the graphics will be difficult to see against a dark background. Finally, since this technique does require high heat, heat-sensitive cloth cannot be used.

Pros

- The ability to fulfill custom requests; the photographic clarity and image quality

- The variety of materials, including glitter (sparkles, silver, and gilding), vinyl (flex) films, and velvet (flock)

- Low cost of drawing in short print runs; resilience to fading and abrasion

Cons

- Low effectiveness for large orders

- Weak impact for dark clothing

- Risky for heat-sensitive textiles

Discharge Printing

One way to decorate colored fabric is through discharge printing, also known as extract printing. It still has a name even though it isn’t used very often. A light or white design is bleached out on the base color that is darker by printing a color-destroying substance, such as hydrosulfite or chlorine. Despite being less frequent than the other types of shirt printing, this one creates standout shirts. The procedure necessitates removing paint rather than adding more!

Equipment required: Ventilation and a conveyor dryer

In terms of layout, discharge printing resembles bleaching a little bit, but it doesn’t damage fabric the way bleaching would. The weaving of the shirt is revealed in the incredibly fine print that is created. Using this technique as a foundation for other colors without pigments is also an option.

While pigmenting discharge, it could be difficult to achieve precise color results. Due to the discharge’s ability to affect the hue, this may occur. The pigments do not always produce the same colors when mixed with what your unaided eye sees. But, it is still a fantastic way to add color to gloomy garments. Due to the ink’s lack of skin-irritating effects, discharge printing is a safe technique. Water utilization makes it environmentally friendly.

Comparable to traditional screen printing, this technique. Before the remaining color is bleached off, you must use a stencil provided by the printer to save a section of the t-shirt design. Special emulsions are also required to prevent the stencil from disintegrating while printing is being done.

To create trendy t-shirts that look vintage, you might wish to try this process at home with a group of friends. With color discharge printing, an impermeable dye is used with the bleaching agent to create a design on a dyed base rather than a white background. Because of its construction using a water-based discharge agent, it is quite mild on cloth. For sensitive materials, discharge printing is used as a result.

Pros

- Unique appearance

- Shirts in the vintage style

Cons

- Costly for both individuals and businesses

- Time-consuming

Selecting a T-Shirt Printing Method: Important Considerations

You may select the best t-shirt printing method for you now that you know the many techniques. You can choose a method that will meet your needs and provide the best quality based on your specifications to achieve your objectives. Some factors that may affect your decision are as follows:

Compatible With A Variety Of Fabrics

Each technique has the optimum types of shirt prints, and not all procedures are suitable for all sorts of cloth. Dye sublimation, for instance, is not ideal for thick cotton T-shirts since it will ruin them.

Cost Vs Production Capacity

Costs for printing can differ greatly. In general, printing equipment costs increase with printing speed. While looking to start, be cautious to weigh the cost against the production speed. You shouldn’t employ a slow method if you need hundreds of shirts printed rapidly.

FAQs

Which Printing Technique Works Best On Shirts?

Plastisol Transmits. This printing technique, also referred to as indirect screen printing, is fantastic. Plastisol heat transfers are the recommended material for t-shirt printing since they produce quite acceptable results and have a very soft feel.

Which Shirt Print Has The Best Longevity?

The prints that are thought to last the longest are screen prints and sublimated prints. Since screen printing has been practiced for a long time, there are numerous variations in the technique. The most common method of t-shirt embellishment, particularly for slogans and cartoons, is screen printing.

What Printing Technique Is Most Effective For Small Businesses?

Using heat transfer printing, you can realize your desire to own a POD store. It is affordable, doesn’t require stocks, and good skills are not necessary.

How Can You Print T-shirts At Home?

Pick up a pillowcase, a t-shirt, scissors, t-shirt transfer paper, and a clothing iron. Lay your shirt on top of the pillowcase, which should be flat on a hard surface. Print your design on transfer paper, adhere it to your tee, and iron over the message for about a minute, or for however, long your paper’s instructions advise.

Final Words

The information in this article is intended to help you understand how various shirt printing type work.

If you’re considering how to start a t-shirt business, it’s so simple and satisfying with print-on-demand, after all. If you come up with original designs or print-for-business t-shirt design ideas, t-shirt printing can be a successful business.

There are different types of t-shirt printing methods, and the technique you choose is largely dependent on your needs and chosen printing technique. Even if it’s only for fun, anyone may easily enter the t-shirt printing industry because of the wide price range.