In garment production, knowing pattern making and cutting is crucial. This stage sets the base for creating your t-shirts. Understanding this process helps in turning materials into wearable items. Also, learning about the different seams used by t-shirt manufacturers shows the craft and detail in garment making.

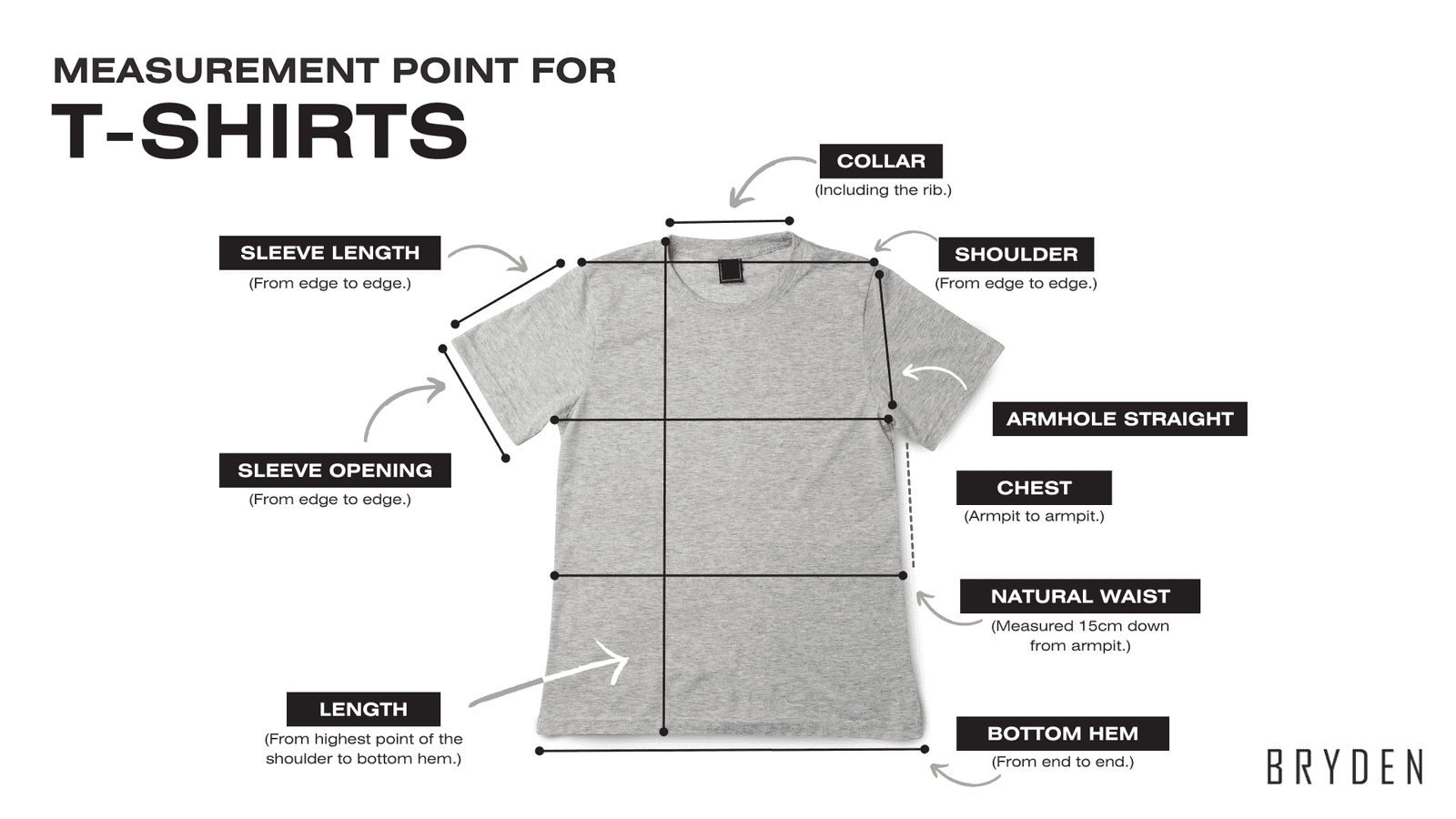

Recognizing the key measuring points of t-shirts allows for a better understanding of garment sizing and how it impacts the clothing design.

In this article, you’ll also look into printing, dyeing, and washing techniques in the textile industry. Knowing these techniques enhances your knowledge of garment production.

For additional information about the design process and the different parts of t-shirt, see the T-shirt manufacturing series parts 1 and 2.

Pattern Making And Cutting

The next step when making the t-shirt is the pattern and cutting. There are specific cuts used for certain styles, depending on your design. That is why you must ensure that you are taking the exact measurements to avoid mishaps.

Pattern Making

The most crucial step in creating garments is pattern making. But, once finalised, t-shirt manufacturers can use this blueprint to grade different sizes for the bulk manufacturing process.

By then, they can create numerous variations of your design. Here are a few steps they take when creating a pattern:

1. Preparing the tools and design

First, they prepare the rough outline or sketch for your design. This step is very important to ensure your design comes to life. When preparing for your pattern, they also consider any flairs or puffs your shirt will have.

Tools like fabrics, pins, pattern paper, and specific rulers like a French curve and a straight ruler are being used to create the pattern.

2. Decide how to make the pattern

There are two ways to make the pattern for the garment: draping and pattern making.

-

Draping

After placing your clothes on the dress form, they begin to mark the individual pieces. Next, check to see if the lines are clean. These pieces are then transferred to pattern paper. Because the material follows the shape of the dress form, your measurements will be more precise.

-

Flat pattern method

In this pattern method, they simply estimate the measurements to draw the pattern directly on the paper.

3. Add details

When making the pattern, t-shirt manufacturers add some curves, notches, and seam allowance to turn the inside out. If you miss these small cuts, then the fabric will look odd.

4. Digitize the pattern

One of the best ways to reproduce the pattern is through a digital pattern. They then label information and care instructions on these patterns and print them out to be used for cutting the patterns on the fabric.

Cutting and Sewing In T-Shirt Manufacturing

T-shirt manufacturing requires the correct pieces and stitches. Garments must fit perfectly so that they don’t feel restrictive or ill-fitting. Here’s a step-by-step guide on a t-shirt manufacturer’s cut & sew process.

Cutting Fabrics

The fabric pieces and cuts are crucial in t-shirt manufacturing. These elements are of utmost importance as they directly impact the comfort, fit, and durability of the t-shirt.

Manufacturers employ various cutting techniques to create different styles, including crew neck, V-neck, scoop neck, and raglan sleeves, among others. There are many cuts available that can complement different body types and aesthetic appeal.

Furthermore, the cutting process requires precision and attention to detail to guarantee accuracy and consistency in the finished product.

By the way, always give your cuts extra seam allowance. You can always take excess fabric. But you can’t glue those cuts back. So make sure your measurements are exact.

Here are some tips on how to cut the t-shirt:

1. According To Style

Before cutting the t-shirt, your t-shirt manufacturing supplier will prepare the finalised t-shirt design and pattern. They double-check the measurements and placement based on the style of the t-shirt. Along the way, they’ll adjust the size differences and stylistic preferences based on your approval.

2. Cutting The Pieces

Once the preparation and quality checking are complete, they’ll then cut the t-shirt sections separately. They’ll then follow the pattern’s dimensions.

These portions should include the following:

- Body

- Back

- Sleeves

- Bottom

- Collar

Understanding T-shirt Seam Construction When Sewing

The next step in the t-shirt manufacturing process is slowly piecing together the fabrics to make the garment. To piece the t-shirt together, you have to first understand the different types of seams your t-shirt manufacturer will use and the different measurement points you have to understand.

There are also additional tips to follow to prevent fraying. These techniques mention stitching the hem and reinforcing the seams.

Different Types of Seams

There are various types of seams used in sewing and garment construction. These seams play a crucial role in ensuring the durability and quality of a garment. Let’s explore some of the most common types of seams.

1. Plain seam

It is also known as the open seam or regular seam. It is the simplest type of seam where two fabric pieces are stitched together with the right sides facing each other. The edges are then trimmed and finished to prevent fraying.

2. Double-stitched seam

A double-stitched seam is a type of seam that is similar to a plain seam but with the addition of two lines of stitching. These extra lines of stitching provide extra strength to the fabric, making it more durable and resistant to tearing.

3. French seam

This type of seam is often used for delicate fabrics or garments where a clean finish is desired. The French seam involves stitching the fabric’s wrong sides together, enclosing the raw edges within the seam. This creates a neat and tidy appearance on both the inside and outside of the garment.

4. Flat-felled seam

For heavy fabrics or items that require extra strength, a flat-felled seam is often the go-to choice. This seam is commonly used in denim jeans and workwear. It involves sewing two fabric pieces together, then folding and stitching one of the seam allowances down to encase the raw edges. This creates a strong and durable seam that is less likely to unravel.

5. Serged seam

If you’re working with knit fabrics or stretchy materials, a serged seam is often used. A serger is a specialised sewing machine that trims the fabric edges while stitching, creating a clean finish and preventing fraying. This type of seam is commonly found in sportswear, activewear, and lingerie.

In addition to these basic seams, many other variations and decorative seams can be used to add interest and detail to a garment. Some examples include the topstitched seam, the mock flat-felled seam, the French seam with a decorative stitch, and the piped seam.

Understanding the various types of seams and their applications can greatly enhance your knowledge of t-shirt manufacturing. It allows you to provide input on what type of seam you want and create professional-looking garments.

Guide to Measurement Points for T-shirts

The measurement points for T-shirts are crucial for ensuring a perfect fit and comfort. These points help determine the size and shape of the T-shirt, allowing you to choose the right one for your body type.

1. Shoulder Width

The shoulder width measurement is taken from one shoulder seam to the other. This measurement ensures that the T-shirt sits correctly on your shoulders, providing a comfortable fit.

2. Neck to shoulder

The neck-to-shoulder measurement point is where the t-shirt’s neckline transitions into the shoulder area. Start at the base of the neck and measure horizontally across to the point where the shoulder seam begins.

3. Chest Circumference

The chest circumference measurement is taken around the fullest part of your chest. It helps determine the overall size of the T-shirt and ensures that it is neither too tight nor too loose.

4. Waist Circumference

The waist circumference measurement is taken around your natural waistline. This measurement helps determine the T-shirt’s fit around your waist area, ensuring that it is neither too tight nor too baggy.

5. Sleeve Length

The sleeve length measurement is taken from the shoulder seam to the end of the sleeve. It helps determine the desired sleeve length, whether you prefer a short-sleeved, three-quarter-sleeved, or long-sleeved T-shirt.

6. Shirt Length

The shirt length measurement is taken from the highest point of the shoulder to the bottom hem of the T-shirt. It ensures that the T-shirt is the right length for your body, allowing you to move comfortably without it being too short or too long.

7. Hem

The hem refers to the bottom edge of the garment, where the fabric is folded and stitched to create a neat and finished look. Locate the hem of the t-shirt and measure it until you reach the other end.

These measurement points help your T-shirt manufacturer produce a t-shirt that fits well and also complements your style.

The Art of Printing

Printing on t-shirts is more than digitizing copies and sticking them directly to fabric. There are several methods and techniques for printing that t-shirt manufacturers use. Some of these include:

1. Screen Printing

Screen printing is one of the most traditional methods to transfer designs and ink onto fabric. This method is also called silkscreen printing. This technique uses hand-cut stencils made out of self-adhesive film which is then attached to a mesh screen.

T-shirt manufacturers usually use various sizes of screens and a rotating board, these boards make it easier to print without changing another screen.

Once the t-shirt patterns are all lined up, the printing process is printed by hand or using automated machines.

2. Heat Transfer

One of the most popular printing methods uses heat transfer film and paper to adhere artwork on the fabric. You can transfer the design from paper to fabric by applying pressure and heat. Heat transfer printing is popular with graphic designs and elements. This method is popular with streetwear and bold text.

3. Sublimation

Sublimation printing uses a special paper to apply to the fabric. It also uses heat and sublimates on the shirt. That means the solid print turns into gas and transfers to the shirt. This method is commonly used for printing jersey shirts and can only be used on polyester fabrics.

4. Digital Printing

Digital printing is a different print method commonly used on t-shirts The key difference between digital and other printing methods like screen printing is that digital print allows printing of full colours, more colours and photo quality images. Unlike screen printing, where the more colours you have will add to your cost, digital printing for colourful artwork is a more affordable option.

5. Direct-To-Garment Printing

There are specific printers that place the design directly on the fabric. Direct-to-garment printers use inkjet technology. That’s why the colour looks bright and vivid. The ink absorbs into the fabric, resulting in a full-color and high-quality printed design.

Different Types of Garment Washing

Garment-washing techniques can give your clothing a unique texture and appearance. In the textile industry, there are various types of garment-washing techniques that are used to enhance the appearance, comfort, and durability of clothing items.

1. Enzyme washing

One popular type of garment washing is enzyme washing. This technique uses enzymes to break down the fibres of the fabric, resulting in a softer and more comfortable texture. Enzyme washing is commonly used on denim jeans to achieve a worn-in look.

2. Stone washing

This method involves washing the garments with pumice stones to create a faded and distressed appearance. Stone washing is often used on denim and is known for giving jeans a vintage and casual look.

3. Bleach washing

As the name suggests, it involves the use of bleach to lighten the colour of the fabric. This technique is commonly used to create a faded or bleached effect on jeans or other garments.

4. Acid washing

This is a technique that involves treating the fabric with a corrosive acid to create a unique and irregular pattern. Acid washing is often used on denim to achieve a distinctive and edgy look.

5. Sand washing

This garment-washing technique is called sandblasting, which involves using sand particles to create a worn-out effect on the fabric.

Additionally, specialized techniques like ozone washing, laser washing, and ice washing are used to create specific effects on garments.

Remember that in order to guarantee the safety of the finished product and its quality, these garment-washing procedures should only be carried out by qualified professionals who have the necessary expertise and equipment.

By utilising different types of garment washing techniques, t-shirt manufacturers and designers can create unique and visually appealing clothing items that cater to the diverse preferences of consumers.

Fabric Dyeing Technique

Fabric dyeing is a technique that involves imparting colour to fabric to create vibrant and eye-catching designs. Whether you want to revamp an old garment or add a unique touch to a new one, fabric dyeing allows you to unleash your creativity and personalize your wardrobe.

1. Tie-dye

One popular fabric dyeing technique is tie-dye. Tightly tying sections of fabric and applying dye to the exposed areas allows you to create captivating gradients and patterns with tie-dye. This technique is known for its bohemian aesthetic, and it’s a great way to add a playful and artistic vibe to your clothing.

2. Dip-dye

Another technique is dip-dyeing, which involves immersing fabric in a dye bath to achieve a uniform colour. This method is perfect for creating ombré effects, where the fabric transitions from one shade to another. Dip-dyeing can be done with multiple colours to create a striking and dynamic look.

3. Hand-Painting

For those who prefer a more controlled approach, there is also hand-painting. With hand-painting, you can use brushes or even your fingers to apply dye directly to the fabric. This technique allows for intricate designs and detailed artwork, making it a favourite among those who love to experiment with different motifs and illustrations.

4. Shibori Dyeing

If you’re feeling adventurous, you can also try shibori, a Japanese dyeing technique that involves folding, twisting, and binding fabric to create unique patterns. Shibori offers endless possibilities for creating one-of-a-kind designs, and its rich cultural history adds an extra layer of intrigue to the process.

Fabric dyeing techniques offer endless possibilities for transforming plain fabrics into personalized works of art.

Dyeing allows you to transform the colour of your clothing, giving them a whole new look. From vibrant and bold hues to subtle and pastel shades, you can choose the colour that best suits your style and preference. Additionally, you can experiment with different dyeing techniques, such as tie-dye, ombre, or dip-dye to create eye-catching patterns and designs.

Quality Control and Measures

The most crucial aspect of t-shirt manufacturing is quality control. Doing so will ensure that the final product meets the desired specifications and standards. Some of the key quality control measures in t-shirt manufacturing are sizing and fitting.

A lot of these involve taking measurements of the different parts of the garment. Then, compare them against the specified tolerances for each point of measurement.

Fitting Test

Fitting tests are the peak of quality control. An inspector will place the garment on the mannequin to check whether it fits correctly. This test is important for every clothing size to ensure consistency in sizing.

A fitting test requires the exact garment specifications. Make sure to include the sleeve length, neck width, and other standard measurements for each size. Plus, there are also limitations for each point of measurement.

Packaging and Branding

Once the final product is ready, the t-shirt manufacturers label the t-shirts for branding. Labelling and packaging are essential steps for t-shirt manufacturing to ensure that the garments meet consumer product laws and brand requirements. These elements include:

- Labeling: Making your brand includes adding labels. The shirts must have labels that contain important information. These labels contribute to the overall image of your brand and help customers identify your products. They serve as a means of communication, providing vital details such as your brand logos, care instructions, fiber content, and other necessary information.

- Main label: It is the primary label that represents your brand. It showcases your logo and brand name, making your products easily recognizable.. This label helps create a strong brand identity and serves as a symbol of trust and quality.

- Secondary label: This label can be used to provide additional information about your product or brand. It could include details such as product features, sizing information, or special care instructions.

- Wash care label: This label provides instructions on how to properly care for the shirt, including washing, drying, and ironing instructions. It ensures that your customers are aware of the appropriate care methods to maintain the quality and longevity of the garment.

- Packaging: In the clothing manufacturing world, each garment is carefully steam ironed to remove any wrinkles and creases, giving them a pristine appearance. After this, they are neatly folded with precision and attention to detail. This not only helps to save space but also ensures that the clothing retains its shape and form.

- Packaging materials: To protect the garments during shipping and storage, various packaging materials are used.

- Polybags: They provide a lightweight and protective covering for individual items. These polybags are designed to keep the clothing clean and safe from dust and moisture.

- Cardboard boxes: They are often used for bulk shipments, providing a sturdy and secure packaging solution.

T-shirt manufacturers ensure that the packaging of the shirts is based on type and distribution outlet. Some of these are underfolded, boarded, or boxed by the dozen or half-dozen.

Also, pressing t-shirts through steam tunnels before packaging gives them better quality.

The Takeaway

T-Shirt manufacturing involves intricate processes to create stylish garments. To guarantee the highest quality, cutting and sewing procedures are carried out precisely.

Understanding the types of seams is not just about functional elements that hold the fabric pieces together; they also contribute to the overall aesthetics and durability of the garment. By learning about the various types of seams used in t-shirt production, you will gain a better understanding of the process of creating a simple yet versatile piece of clothing.

Thus, you can also build strong relationships with t-shirt manufacturers that share your values and quality standards. This ensures your fashion line stands out for exceptional design and ethical, sustainable practices.

If you’re a brand owner interested in adding custom t-shirts to your collection, please don’t hesitate to get in touch with us. We strive to offer the best customization options available on the market to help your brand.