There’s something undeniably charming about beanies. They’re more than just winter hats; these comfy little head warmers can add a pop of color or a fun pattern to any outfit, instantly elevating your look. Beanies are everywhere, all with a variety of cool designs and colors.

Unique beanie fabrics and patterns are a fantastic way for designers and clothing brands to make their collections truly special. That’s where this guide comes in—we’re here to give you a peek behind the curtains at how beanies are made. It might seem complex, but anyone can learn the steps!

Before we dive in, let’s clear up any confusion – beanies are incredibly versatile! Beanies are different from your typical hat. They hug your head for warmth, unlike hats with wide brims for shade. And forget bonnets that tie under the chin; beanies are all about easy wear.

These versatile hats come in all sorts of styles and patterns, adding a touch of cozy comfort to any collection.

Understanding Beanie Manufacturing

Source: Pexels

Believe it or not, beanies can trace their roots back to 12th-century Wales. Back then, they weren’t just about looking cool; they were a must-have for keeping soldiers and workers warm and dry. Unlike floppy hats, beanies kept hair out of their faces and stayed put during tough jobs.

Fast forward a few centuries, and beanies were still a symbol of practicality. Originally, workers wore them for function—keeping their heads warm and hair out of the way of machinery.

In the 1990s, beanies made a major comeback, this time as a popular fashion statement! Their cozy style and versatility captured hearts (and heads) all over again. Beanies are now seen on athletes, travelers, and anyone who wants to add a touch of casual style to their outfits.

Designing the perfect beanies

Source: Pexels

So, you’ve got your eye on the beanie prize – creating the next must-have winter accessory! But where do you even begin? Designing the perfect beanie is all about bringing your vision to life, and this section will be your guide.

Steps on designing a beanie

1. Setting some goals

Who are you designing these beanies for? Are they for athletes who need maximum warmth and sweat-wicking ability? Maybe you’re creating cozy everyday beanies for people who love to stay comfortable. Or perhaps you’re working on a specific brand collection.

Understanding your target audience is key. It helps you pick the perfect materials, styles, and features that resonate with them. Thus, knowing your ideal customer will guide your design choices.

2. Brainstorm and get inspired

Jump on social media platforms like Instagram or Pinterest and see what kind of beanies are catching people’s eyes. But those are just the public faces of beanie trends. The online world isn’t the only source of inspiration!

Another great way to get inspiration? Ask around! Talk to friends, family, or even potential customers and see what features they look for in a beanie. Do they crave a classic look or something more trendy? Is a soft, snug fit a priority, or are they looking for something with a little more structure?

3. Turn your vision into reality

There are a few ways to tackle the design itself. Feeling artistic? Sketch some beanie ideas or create mood boards that explode with colors, textures, and patterns that fuel your inspiration. What kind of vibe are you going for? Let your imagination run wild!

If you need a starting point, there are free beanie templates that you can customize. Not the most confident artist? Hire a talented professional to translate your ideas into stunning visuals that bring your beanie vision to life.

4. Customization time

Now comes the fun part—customization! Beanies offer a huge canvas for creative expression. Basic beanie? Spice things up with a cool embroidered design, a playful pom-pom, or even your brand’s logo. Or opt for an all-over print like stripes, paisleys, or even a custom design you create yourself. The possibilities are endless!

Planning and creativity unlock the perfect beanie! Design a beanie that keeps people warm and stylish all winter long.

Types of beanies

Before you jump into beanie manufacturing, there’s one more key decision to make – what kind of beanie will it be? This choice will influence everything, from materials to design.

Classic styles or trendy designs – there’s a beanie out there to perfectly match your vision. This dazzling array of beanie styles offers something for everyone, with each one boasting its own unique look and feel.

Source: Maxtern Media

Source: Maxtern Media

Cuffed beanie

Source: Mountain Sports

A timeless crowd-pleaser, this beanie features a folded brim for a customizable fit. Want a snug feel around your ears? Keep the brim rolled down. Feeling a little warmer? Unroll it for a looser look.

Slouch beanie

Source: Amazon

Looking for a comfy and casual vibe? The slouch beanie is your friend! Ideal for relaxed days, it boasts a longer silhouette that drapes casually over your head. Think cozy vibes and effortless cool.

Brimmed beanie (or visor beanie)

Source: Ubuy Philippines

Brimmed beanies, also known as visor beanies, add a sporty touch with their short, stiff brim. Great for sun protection or a more structured look.

Classic styles are awesome, but let’s explore more! Here are the other beanie styles that is a perfect fit for your brand.

High Top beanie

Source: Epitome of Edinburg

For those who prefer a defined silhouette, the high top beanie is your best bet. It has a taller crown than other beanies, creating a cool silhouette.

Earflap beanie

Source: Chaos Hats

Need extra warmth for those chilly days? Look no further than the earflap beanie! This beanie features built-in flaps that you can tie or secure under the chin for toasty ears.

Crochet beanie

Source: Pinterest

Step away from the ordinary and embrace the unique! Crocheted beanies, crafted with care, add a personal touch to your wardrobe. Each piece radiates charm, available in an inspiring selection of colors, patterns, and textures. Endless customization awaits!

Here are some additional beanie styles to consider:

Bobble beanie

Source: Ronhill

Embrace the joy! This playful style, also known as pom-pom, adds a touch of whimsy with its signature fluffy yarn ball. Think bright colors and quirky patterns for maximum fun!

Skullcap beanie

Source: Candid Signature

Less is more with the skullcap beanie. The snug-fitting beanie offers clean lines and a simple design, letting your other accessories take center stage.

Mohair beanie

Source: Mohawk General Store

Mohair beanies redefine luxury. Incredibly soft with rich texture, they elevate any outfit with a touch of sophistication.

Fisherman beanie

Source: Ebay

Channel nautical vibes with the fisherman beanie. This timeless style features a classic ribbed knit pattern and a folded brim, perfect for those who love a touch of maritime inspiration.

Baseball beanie

Source: Ebay

Inspired by baseball caps, this beanie offers a comfortable and casual option with a wider brim and rounded crown.

Military beanie

Source: Amazon

Built for tough conditions, the military beanie is based on styles worn by military personnel. Typically made from wool, it features a simple and practical design.

Building your clothing brand? A world of possibilities awaits—a wide range of fabrics and styles ready to bring your beanie vision to life. Classic cuffed styles or playful pom-pom wonders—there’s a perfect beanie for every occasion and every collection you design.

Anatomy of garment

So, you’ve chosen your perfect beanie style—awesome! But beanies are more than just a pretty face (or head, in this case). Each one tells a story, not just through its design but also through its construction. You might be surprised to learn that even a simple beanie has different parts.

What are the parts of a beanie?

A beanie might seem simple, but it has a few key parts:

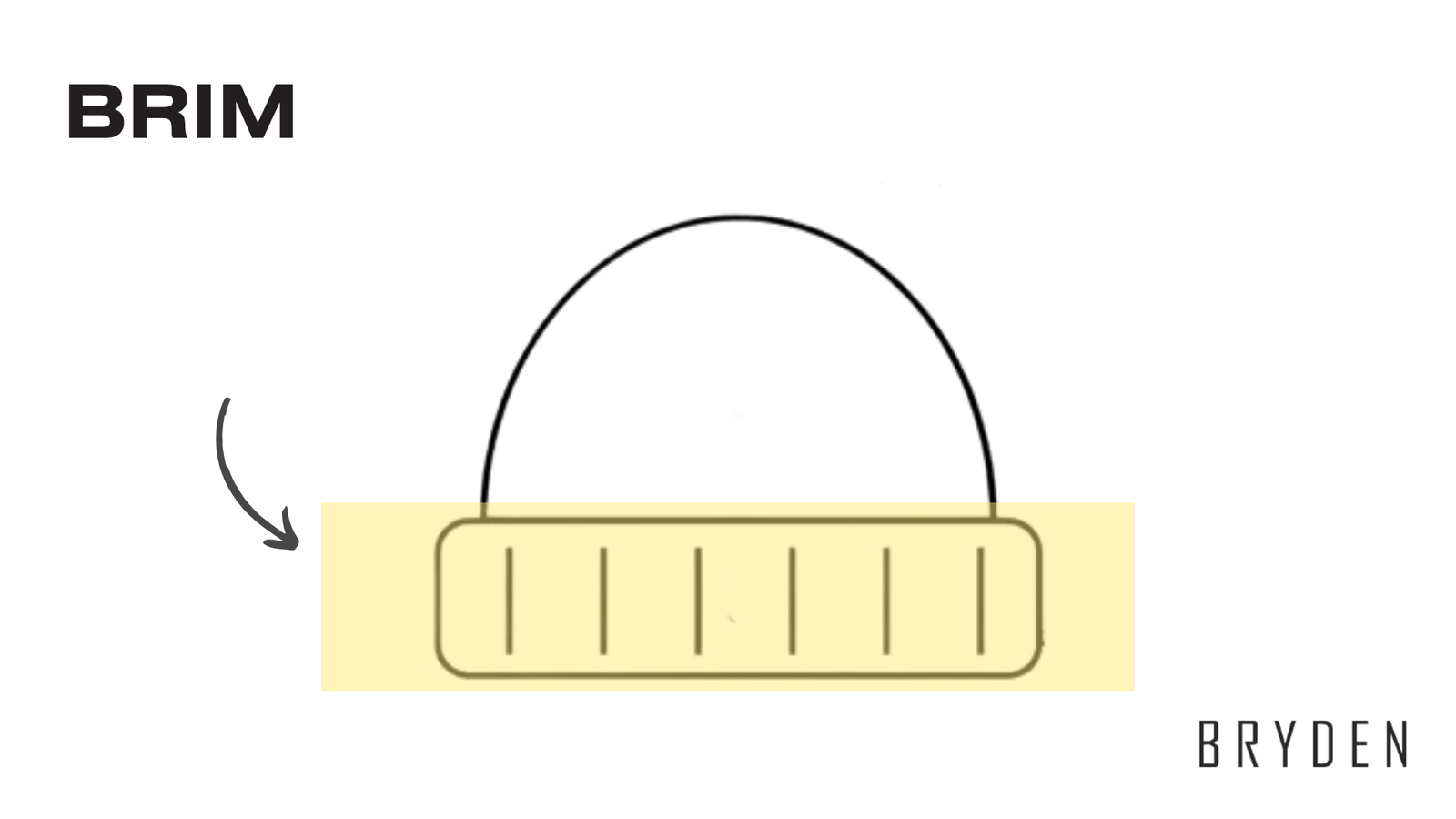

Brim

This is the folded edge at the bottom of the beanie that fits around your head.

Body

The main part of the beanie that covers your head. On a beanie, the brim flows smoothly into the body, creating a seamless look.

Crown

The top part of the beanie. It can be rounded, pointed, or slouchy depending on the style.

Beanies also have additional parts:

Cuffs

A folded section at the brim that can be rolled up or down for a tighter or looser fit.

Tip

The very top of the beanie. It can be pointed, rounded, or have a pom-pom attached.

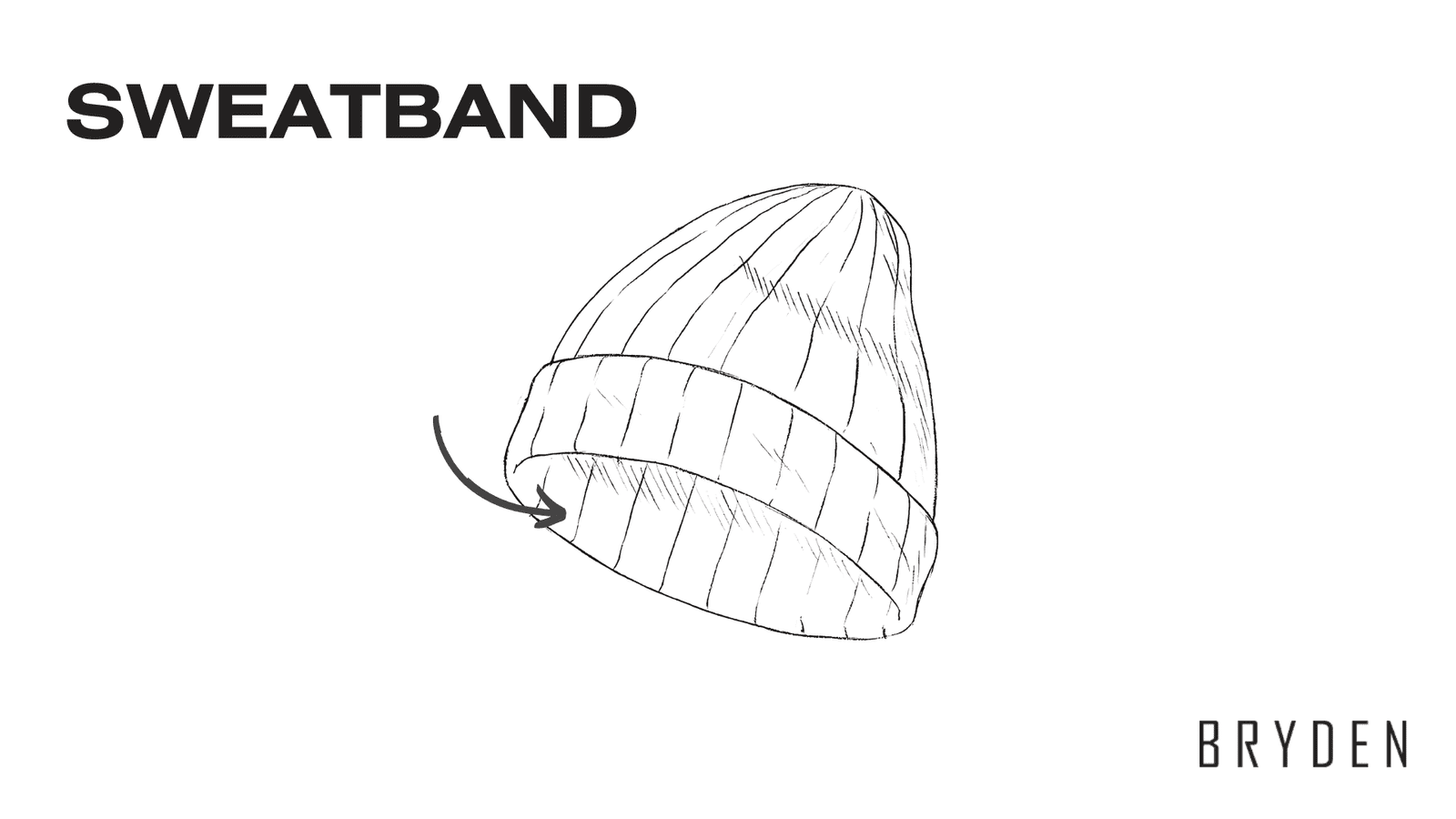

Sweatband

An optional inner band that absorbs sweat and keeps the beanie comfortable to wear.

Decorations

This could be anything from embroidery to patches to buttons, letting you add a personal touch to your beanie design.

Understanding these parts allows us to create beanies that are not only stylish but also functional and comfortable. Now that you know the beanie basics, let’s talk about the fun stuff – picking the perfect fabric for your creation!

Choosing quality fabrics

Source: Unsplash

Fabric is the foundation of any great beanie, influencing its look, feel, and quality. Ready to dive into the options? Various beanie fabrics are available, both natural and synthetic, each with unique advantages and considerations.

Natural Fabrics:

1. Wool

The classic beanie choice! When battling the cold, wool reigns supreme. Breathable and water-resistant, it’s perfect for chilly days. Just a heads-up: wool can be itchy and needs extra TLC.

2. Cotton

Want a light and airy head? Seek out cotton beanies for a light, airy touch. They promise supreme comfort and breathability for daily wear. The only catch? They’re not the warmest option for very cold days.

3. Hemp

Durable and eco-friendly, hemp beanies are a rising star. They start off stiff but get comfier over time.

Venture beyond traditional choices and explore beanies made from other natural fibers. Rayon, silk, linen, and bamboo add a unique twist to headwear. These options often offer unique textures and properties.

Synthetic Fabrics:

1. Nylon

Built to last! Enter nylon – the champion of strength and durability. Perfect for those who endure heavy wear and tear. The drawback? Nylon isn’t particularly breathable.

2. Polyester

A popular choice for its affordability and softness, polyester beanies are easy to care for. While comfy, polyester beanies might trap sweat – ideal for cooler days, not intense workouts.

3. Acrylic

Looking for a wool substitute? Acrylic provides a soft, warm, and budget-friendly alternative to wool. It’s ideal for those seeking a wallet-friendly beanie. However, be aware that it can be itchy for some individuals.

4. Rib knit

Don’t be fooled! Rib knit isn’t a material, but a knitting technique for a stretchy, textured look. It works with any fabric listed above!

Fabrics shape the look, feel, and quality of a beanie. They also impact the manufacturing process. Luxury and durability often come at a price with natural fabrics. Synthetics offer affordability and variety, but may not feel as luxurious.

Beanie manufacturers discuss all these factors with designers and clothing brands to ensure the perfect match for their needs.

Pattern making and cutting

Pattern making and cutting are the foundation of beanie manufacturing. Every beanie starts with a vision. We imagine the beanie on someone’s head, keeping them warm and stylish. Then, we create a pattern specifically for your beanie design. This pattern is like a blueprint, ensuring each beanie is made to your exact specifications.

In the next step, we carefully cut the fabric based on the pattern. Cutting the fabric is precise work. We use sharp tools to follow the pattern’s lines. This ensures each beanie piece is the right shape and size. Once the fabric is cut, it’s on to the sewing stage.

Pattern making (How to with samples)

We know the importance of a perfect pattern. A well-made pattern ensures consistent size, fit, and style for every beanie. While we handle the pattern-making for your order, let’s explore some general tips for different beanie styles.

1. Basic cuffed beanie

Source: The Last Stitch

Source: The Last Stitch

This classic style requires a simple, rounded pattern. The key here is getting the right head circumference and height for a snug but comfortable fit.

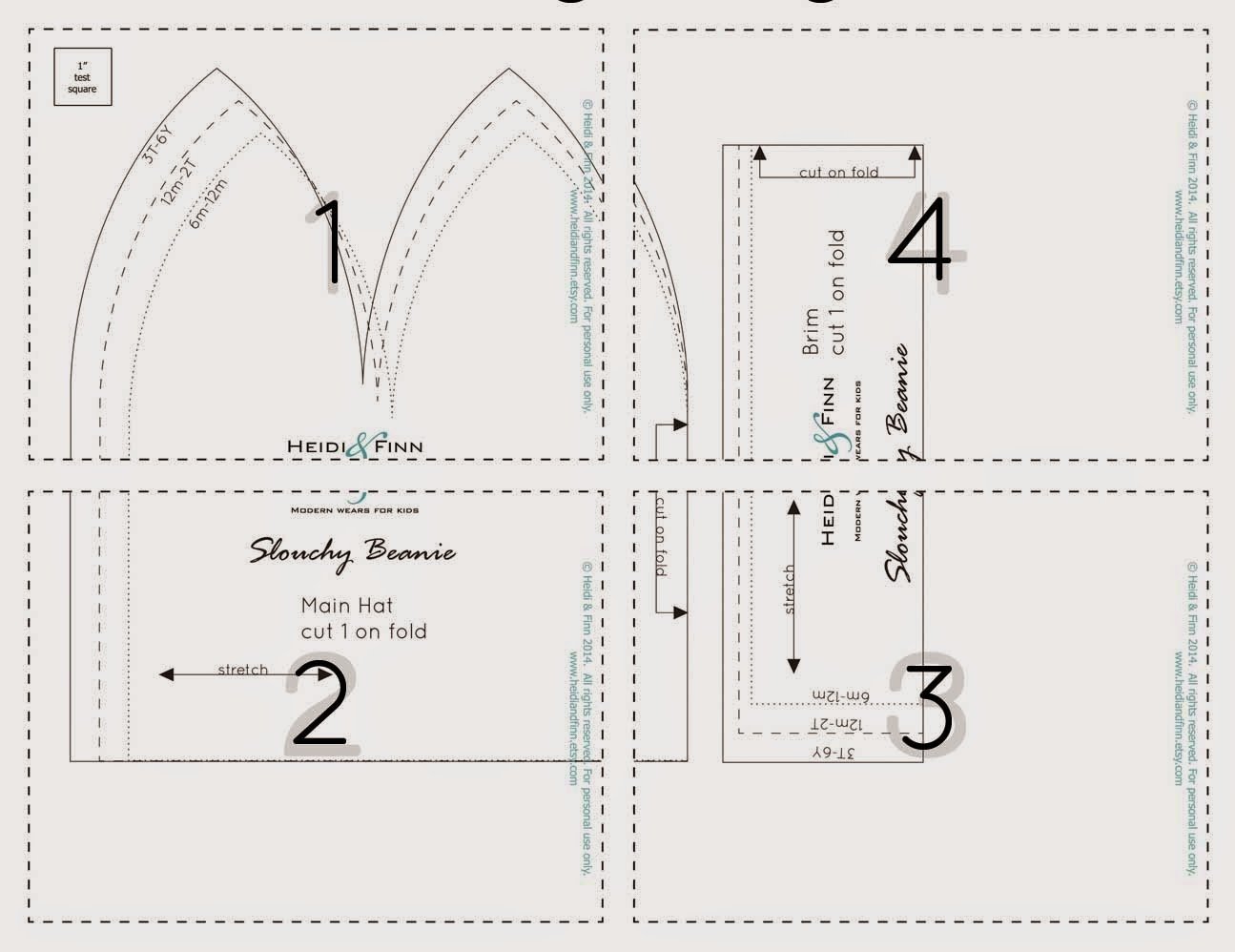

2. Slouch beanie

Source: Heidi & Finn

Source: Heidi & Finn

For that signature slouchy look, the pattern needs to be taller than a basic beanie. It can also be slightly wider to allow the fabric to drape loosely over the head.

These are just a few examples, and the pattern details will vary depending on your specific beanie design. But remember, a well-crafted pattern is the foundation for a fantastic beanie!

Marking tips for cutting patterns on fabric

Manufacturers use precise methods to ensure clean cuts and consistent results. But for those curious about the process, here are some handy marking tips:

1. Pinning Power

We often secure the pattern to the fabric with pins. This keeps everything in place before we carefully cut around the pattern, leaving you with perfectly shaped beanie pieces.

2. Tracing Technique

Another method involves placing weights on the pattern or pinning it down. Then, we trace the pattern pieces onto the fabric with a marking tool. This way, we can double-check the markings before cutting the fabric.

No matter the method, we always make sure to mark both layers of fabric before cutting. This ensures both pieces match perfectly when sewn together.

We also use the right tools for the job! Depending on the fabric, we might use fabric pencils, chalk, or even water-soluble markers. These markings might be notches, dots, or lines; they help ensure everything lines up perfectly when you sew the beanie together.

And before marking your entire project, we always test the marking tool on a scrap of fabric first. This way, you can be sure the marks will come off easily once the cutting is done.

Following these simple tips can ensure accurate and stress-free pattern marking, paving the way for a great beanie.

Cutting and sewing in beanie manufacturing

Since your beanie pattern is already marked on the fabric, it’s time to bring it to life! Cutting and sewing are the cornerstones of beanie manufacturing. Skilled craftspeople and top-notch equipment are the secrets behind flawless beanies. Manufacturers take pride in creating high-quality beanies that you’ll love.

How to cut beanies

The cutting process can vary depending on the size of the order.

- For smaller orders, we meticulously cut each beanie piece by hand, ensuring accuracy and attention to detail.

- For larger orders, we use specialized cutting machines that precisely cut multiple layers of fabric at once. This ensures consistency and efficiency.

Once the pieces are cut, our skilled sewers take over.

- They expertly stitch the beanie pieces together, following your specific design.

- This typically involves sewing the side seams first, then the crown seam, and leaving a small opening for turning the beanie right side out.

- After all the stitching and shaping, we neatly close the beanie’s opening. And those finishing touches, like a folded brim, add that extra flair.

Don’t be fooled by their simplicity; making quality beanies takes experience and skill.

Manufacturers are pros at ensuring your beanie is not only beautiful but also comfy and built to last. They’re passionate about creating beanies you and your customers will love.

Different types of seams for beanies

We talked about sewing beanies, but did you know there are different types of seams? Seams are the stitches that hold a beanie together. Choose the perfect seam based on your beanie’s design and fabric.

Source: Pixabay

Source: Pixabay

For beanies, we typically use seams that are strong, stretchy, and comfortable against the skin. Listed below are a few common options

1. Plain seam

A basic workhorse, the plain seam joins two fabric pieces together. Strong and simple, it’s a popular choice for many beanies.

2. Serged seam

This seam utilizes a special machine that cuts and encases the raw edges all at once. It’s a great option to prevent fraying and create a clean finish.

3. French seam

This classic choice encloses the raw edges of the fabric inside itself, creating a smooth and comfortable finish on both sides of the beanie.

4. Flat felled seam

Known for its strength, this seam flattens out the raw edges and stitches them down. It’s a good option for areas that get a lot of wear and tear, like the crown of a beanie.

5. Bound seam

This decorative seam uses a strip of fabric to enclose the raw edges. It adds a design element and can be used to incorporate contrasting colors or patterns into your beanie.

Each seam offers unique advantages – consider strength, clean finish, comfort, and visual appeal. With a variety of seams at your disposal, you can achieve different looks and functionality for your beanie.

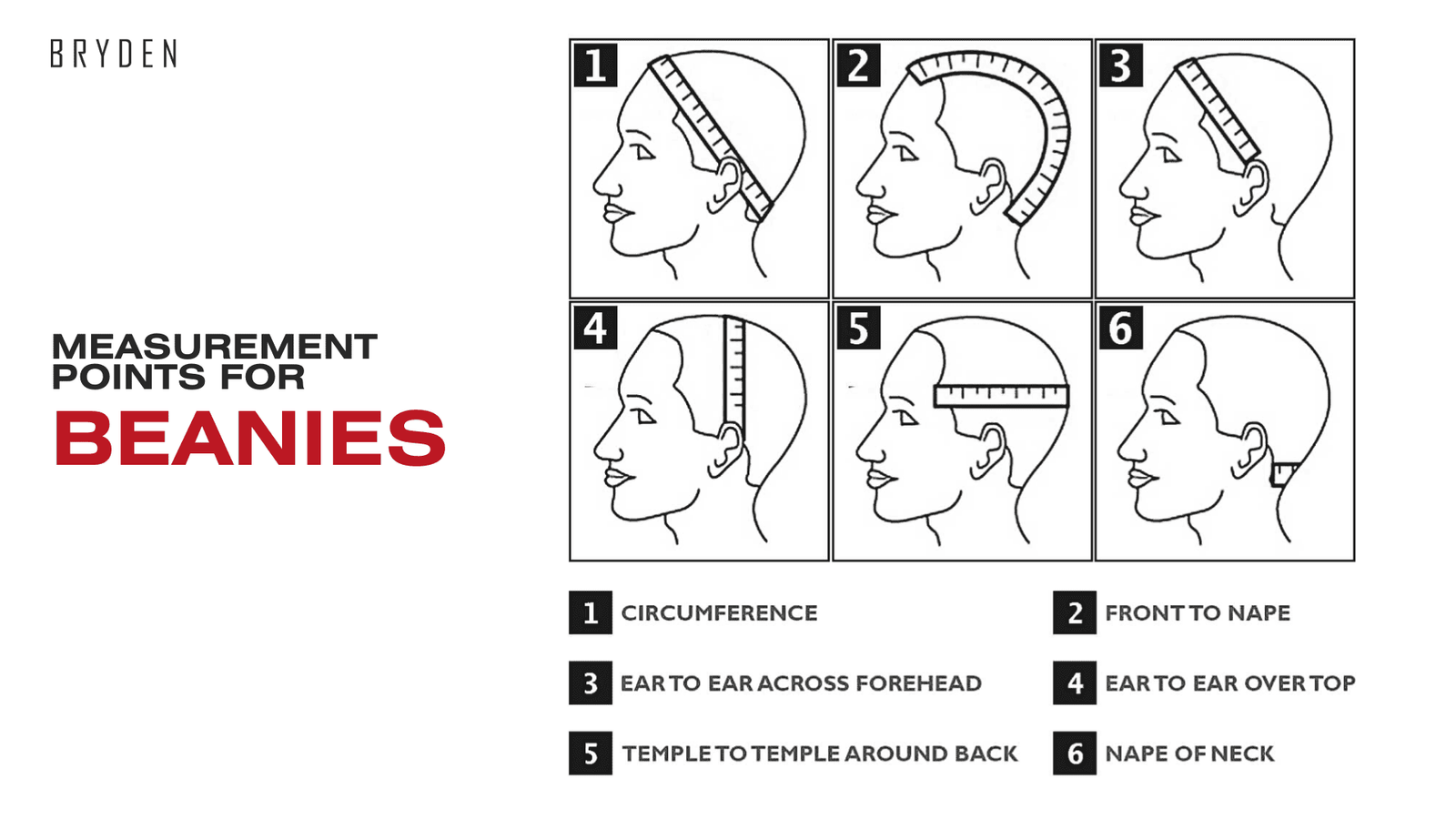

Measurement points for beanies

One size doesn’t always fit all, even with beanies! While the stretchy nature of beanies offers some flexibility, getting the measurements right is key for a comfortable and stylish fit.

Even though beanies stretch, they shouldn’t be too loose or too tight. Thus, there are a few key measurement points that we should consider.

1. Head circumference

This is the key measurement! Measuring the distance around the widest part of your head is crucial, typically just above the eyebrows. Make sure your beanie hugs you right!

2. Ear to ear (over the head)

Imagine a headband route – from the top of one ear, over the head, to the top of the opposite ear.

3. Temple to temple (around the back)

This measurement travels from one temple, around the back of your head, to the other temple.

4. Nape of neck

This measures from the base of your neck to the crown of your head. Need a longer beanie for extra warmth or a shorter one for a snug fit? This measurement helps!

Size charts are vital. Using standard sizing allows us to manufacture beanies that fit a wide range of people. Nobody wants a beanie that’s too snug or keeps slipping off, right?

Following this allows customers to find the perfect size, whether they’re in the US or abroad. This ensures our beanies are comfortable, stylish, and just the right size for anyone, anywhere.

The art of printing

Don’t underestimate the power of the beanie! It’s more than just a way to keep your head warm. Think of it as a blank canvas waiting for your creative spark. Personalize them to reflect your unique style, and suddenly, they’re wearable masterpieces. And there are a variety of printing techniques to bring your beanie design to life.

Common printing techniques used for beanies

There are several ways to add logos, patterns, or text to your beanie. Here are a few of the most popular options:

1. Heat Transfer Printing

Source: Pinterest

Want a one-of-a-kind beanie? Heat transfer lets you print a design onto a special film and then iron it onto the fabric. Easy and awesome!

2. Screen Printing

Source: Gabriel Screen Printing

Source: Gabriel Screen Printing

Classic screen printing uses a stencil to push ink through a mesh screen, creating a crisp design on your beanie.

3. Inkjet Printing

Source: BHCM

Great for intricate designs, this method uses a digital printer to directly apply ink onto the fabric. It’s also a good option for small orders.

4. Sublimation Printing

Source: Sewfits

Source: Sewfits

Imagine the heat working its magic, pressing dye into the fabric for vibrant, lasting designs. Ideal for light-colored synthetics, especially polyester.

Consider your design complexity, budget, and desired outcome when choosing a printing technique. Manufacturers will guide you to create a truly unique beanie.

Different types of garment washing for beanies

Garment washing isn’t just about getting the dirt out – it can actually transform your beanie’s look and feel. This process uses special techniques to achieve specific effects, adding a unique touch to your design. Think of it as a way to personalize your beanie beyond color and pattern!

There are a few common types of garment washing used for beanies, each offering unique design possibilities:

1. Garment wash

Standard garment washing removes dirt and sweat – perfect for prepping your beanie before embellishments.

2. Acid wash

This technique creates a vintage look by gently fading the color of the beanie. The level of fading can be controlled to achieve a subtle or more dramatic effect, perfectly complementing distressed or retro-inspired beanie designs.

3. Bleach wash

Take your beanie from bright to faded for a trendy, pre-loved look. Bleach can lighten the color or create cool, distressed effects.

4. Pigment wash

This process adds a whole new layer of color to the beanie by applying pigment dyes directly to the fabric’s surface. Achieve special color variations and effects beyond standard dyeing methods.

These treatments can transform your beanies, adding personality and a unique touch that goes beyond color and pattern. The result? Beanies that are both functional and fashion-forward!

Keeping it Clean: Care Instructions for Beanies

Let’s talk about care instructions—those little tags that can make or break a beanie’s lifespan. We want to empower your customers to keep their beanies looking great, so here are some tips for crafting clear and concise care instructions:

Know your fabric

Remember, cotton, wool, and synthetics each play by their own washing rules. Clearly state the fiber content on the beanie tag and tailor the washing instructions accordingly.

Simple is best

Keep it simple for the customers. Short sentences, bullet points—make those instructions a breeze to follow.

Focus on key points

Highlight the recommended washing method (hand wash, delicate cycle, etc.) and water temperature. Mention if dry cleaning is an option.

Washing frequency

Suggest a washing schedule, like every 5-6 wears, to prevent excessive washing that can damage the beanie.

Drying tips

Advise air drying or tumble drying on low heat to maintain the beanie’s shape.

Storage tip

Folding for storage is gentler than hanging. Include this tip to prevent customers from stretching out the beanie.

Clear and concise care instructions empower your customers. With this knowledge, they’ll maintain the quality and longevity of your beanies, leading to happy customers and repeat business.

Fabric dyeing technique for beanies

Beanies come alive in a rainbow of hues. And when it comes to dyeing techniques, the options are endless. Whether you’re into solid colors, bold patterns, or trendy gradients, your beanie manufacturer might just be able to create it all.

Curious about how beanies get their vibrant hues? There are many ways to dye fabric, each offering unique results. Let’s dive into some popular techniques.

Tie Dye

Source: Nike

Ah, tie dye—the classic method that swirls colors into psychedelic magic! It’s like a groovy dance for your beanie. We fold, twist, or bunch the fabric to create those funky patterns. Then, vibrant dyes are applied, creating those eye-catching swirls.

Ombre Dip Dye

Source: Amicale Cashmere

Picture this: a gradual fade from one color to another, like a sunset melting into the horizon. Ombre dip dye is the cool cousin of tie dye—more controlled, less wild. We dip the fabric into a dye bath, starting light and diving deeper for that trendy ombre effect.

Now, choosing the right dyeing technique? It’s like picking the perfect brushstroke for your canvas. Let’s talk options:

Solid Colors

Source: Supreme Community

Source: Supreme Community

For classic beanies in a single color, we use the overdyeing method. This involves completely submerging the fabric in a dye bath to achieve a rich, even color throughout.

Ombre Look

Source: Daily Disco

The ombre dip dye method is your best bet for that trendy color fade. Smooth transitions between colors, sleek and sophisticated. It’s the modern twist your beanie deserves.

Patterns

Source: HAGO House

Feeling artsy? Try tie-dye, shibori (that’s Japanese resist dyeing), or marbling. These techniques unlock a world of intriguing patterns. Swirling tie-dye, geometric shibori with clamps and stitching, and marbling—where dyes float on water, creating a mesmerizing marble effect.

And guess what? These are just a few dyeing tricks up our sleeve. Do you have a specific vision? Don’t hesitate to share it! Beanie manufacturers are ready to help you create unique and colorful beanies that stand out from the crowd.

Quality control measures

Creating top-notch beanies is priority number one for any beanie manufacturer. That’s why quality control measures are strictly followed throughout every step of manufacturing.

Ensuring consistent sizing and fitting is a key part of this process.

Specific measurement points are used to guarantee each beanie matches size expectations.

- When you order a medium, rest assured—it’ll fit consistently, no matter when it was made.

Every beanie gets a thorough inspection for stitching flaws, material imperfections, or printing errors. Only the best beanies make it to you!

This commitment to quality control ensures you receive stylish, comfortable, durable, and well-crafted beanies. You deserve complete satisfaction with every beanie you order.

Packaging and branding

The beanie might be the star, but don’t forget the supporting cast – packaging and branding! These elements create a complete package that reflects your brand identity and excites your customers.

Don’t forget labeling, tags, and packaging – they all play a role in how customers experience your brand. Let’s peek at two brands acing the game:

1. Smeeny Made Wild

Source: Smeeny Made Wild

Source: Smeeny Made Wild

Smeeny wears sustainability as a badge of honor. Their beanies? Knit with eco-friendly materials. And guess what? Their packaging follows suit—100% recycled materials. It’s a beautiful alignment of the brand’s values.

2. Carhartt

Source: Mazeline

Source: Mazeline

A leading beanie producer for years, Carhartt understands the power of packaging. Carhartt celebrated their 130th with a bang. Their special gift box? Not your average cardboard. It mirrored their brand identity, matching classic clothing colors and materials.

Unboxing? More like unwrapping a collector’s gem, complete with a brand book and other goodies.

Manufacturers play a crucial role. They help you create packaging and branding that clicks with your audience. Eye-catching boxes make that stellar first impression, while clear labels ensure everyone gets your brand vibe. Happy customers become repeat buyers, so make it count!

Conclusion

Finding a beanie manufacturer for your startup fashion line can feel overwhelming. Don’t fret—creating your dream beanie is within reach!

We covered everything you need, from fabric selection and dyeing techniques to crafting high-quality beanies with flawless stitching and eye-catching branding.

Building a brand is a journey, and we’re here to support you every step of the way. Calling all designers and fashion brands – if beanie fabrics that ignite your vision exist, we have them! Contact us today to chat! Let’s collaborate to bring your beanie dream to life.