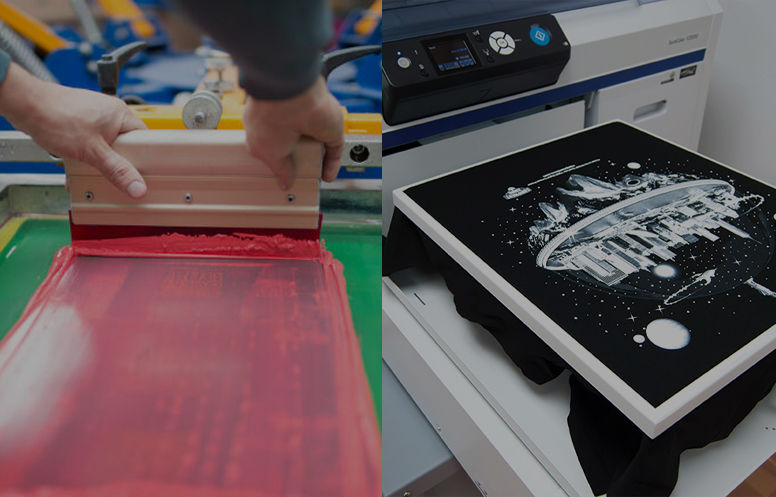

DTG Printing – A Comprehensive Overview

When it comes to printing on clothing, Direct-to-Garment (DTG) printing has fundamentally transformed the industry. This technique uses advanced inkjet technology to directly print designs onto fabric, providing an excellent option for businesses looking for precision and flexibility.

Process Overview

The DTG printing process is both simple and advanced. Using a specialized inkjet printer, designs are printed directly onto fabric much like a standard home printer prints on paper. Water-based ink is sprayed onto the garment, soaking into the fibers, which creates a soft, organic feel. The absence of stencils or screens leads to a faster setup, making it ideal for custom designs and small quantities.

Best Use Cases

DTG printing excels when printing small batches, intricate designs, or personalized items. If your business specializes in custom t-shirts, Custom T-Shirt Manufacturing or other small-scale, detailed designs, DTG is the best method. It’s perfect for print-on-demand services or for businesses that need flexibility without committing to bulk production.

Advantages of DTG Printing

One of the major benefits of DTG printing is that it requires no setup fees for small runs, unlike screen printing that requires creating screens for each design. This makes it a cost-effective solution for smaller orders. Additionally, DTG allows for incredibly detailed, high-resolution prints with vivid colors, making it perfect for designs that require complex color gradients and intricate details.

Limitations of DTG Printing

Despite its advantages, DTG printing has some limitations. The speed of printing decreases when handling larger orders, as each garment is printed individually. This makes it less efficient for high-volume runs. Additionally, for dark fabrics, pre-treatment is required, which can add both time and costs to the process.

Screen Printing – An In-Depth Review

Screen printing is a proven and widely used method for transferring ink onto fabric through a mesh stencil or screen. Whether you’re creating large batches of shirts for an event or developing a clothing line with bold, simple designs, screen printing provides high-quality results.

Process Overview

The process of screen printing involves creating a separate stencil for each color in your design. The screens are placed on the material, and ink is pushed through the mesh to form the design. Each color requires a different screen, and the process is repeated for each layer of ink. While the setup time is longer than DTG, the result is durable and vibrant prints.

Best Use Cases

Screen printing is ideal for high-volume production runs, particularly for businesses that need consistent, cost-effective printing. It works best with basic designs that feature solid colors, such as logos, text, or graphic prints. For larger quantities of the same design, Custom Hoodie Manufacturing or other uniform items are excellent applications for this method.

Advantages of Screen Printing

Screen printing is extremely cost-effective for large orders. Once the screens are prepared, printing becomes fast and inexpensive, making it an economical choice for businesses with high production volumes. Furthermore, the prints created by this method are long-lasting, with bright colors that resist fading even after multiple washes. It is also versatile enough for different fabric types, including t-shirts, hoodies, and bags.

Limitations of Screen Printing

The main drawback of screen printing is its high initial setup cost, especially when dealing with small orders. The creation of multiple screens can make it less cost-effective for small, intricate designs. Additionally, this method is less flexible for on-demand printing or designs that frequently change.

Direct-To-Garment Printing Vs. Screen Printing: A Comparison

Choosing between DTG and screen printing depends on your business’s specific needs. Factors such as production volume, design complexity, and budget should all be considered when deciding on the best method. Let’s compare them based on cost, quality, and production efficiency:

Cost Comparison

Screen printing generally requires a larger upfront investment, especially for small orders, due to the cost of creating multiple screens. However, as production volumes increase, the cost per unit decreases, making it more economical for large runs. On the other hand, DTG printing has lower setup costs, making it a great choice for small orders or businesses that require flexible, on-demand printing.

Design Quality

DTG printing is ideal for complex, multi-colored designs and photos, allowing for intricate details and smooth color transitions. This makes it perfect for Custom Towel Manufacturing or products with highly detailed artwork. In contrast, screen printing is better suited for simpler, solid color designs.

Production Speed and Efficiency

For smaller, customized orders, DTG printing is faster, as it doesn’t require screens or stencils. However, for larger, uniform orders, screen printing is more efficient due to its streamlined setup and faster production speeds.

Durability

DTG prints can last for over 50 washes, maintaining their color and detail, while screen prints generally have a longer lifespan, making them ideal for uniforms or outdoor wear. For example, custom uniforms in Custom Uniform Manufacturing benefit from the durability of screen printing.

Environmental Impact

DTG printing is considered more eco-friendly as it uses water-based inks and produces less waste. Screen printing, while efficient, can have a larger environmental footprint due to the chemicals involved in cleaning screens and the inks used. However, businesses can reduce their environmental impact by opting for eco-friendly inks and sustainable practices.

Customization and Flexibility

DTG printing offers superior customization options, ideal for businesses requiring small runs or personalized orders. Screen printing, while effective for large runs, is less flexible for changing designs and smaller quantities.

DTG vs. Screen Printing: Which is Right for Your Business?

The decision between DTG and screen printing ultimately depends on your business needs. DTG printing is perfect for small, detailed orders or businesses that require flexibility, while screen printing excels in high-volume, cost-effective production. For businesses looking for a balance of both worlds, a hybrid approach can optimize efficiency and meet diverse customer needs.

For all your printing needs, get in touch with Ludyway Apparel, a leading provider of Custom Socks Manufacturing and other customized apparel solutions.

FAQs

What fabrics work best for DTG printing?

DTG printing works best on 100% cotton fabrics, as the ink adheres better. Cotton-polyester blends can also be used, but colors may be less vibrant.

Which method is better for printing on dark-colored fabrics?

Screen printing is ideal for dark fabrics, especially when a white base layer is used. DTG can also be used, but pre-treatment is necessary, adding extra cost and time.

Which method is more scalable for growing businesses?

Screen printing is generally more scalable for businesses handling large volumes. However, DTG is perfect for businesses focusing on customization and smaller runs.

Is screen printing better for outdoor wear or activewear?

Screen printing is ideal for sportswear and outdoor gear due to its durability and resistance to wear and tear.

Can you print photographic images using screen printing?

While screen printing can handle photographic images, DTG is typically better for high-quality, full-color prints.