Modal fabrics were first developed in the early 20th century, but commercial production began in the 1950s by the Austrian company Lenzing AG.

The process involves extracting cellulose from beech wood and converting it into pulp. This pulp is then spun into fibers that are woven or knitted to create fabric.

These fabrics are known for its absorbency, colour-fastness, and shrinkage resistance. Designers and clothing brands seeking comfort and sustainability often choose this fabric for its unique properties and minimal environmental impact.

What Is Modal Fabric?

This fabric is a soft, breathable, and versatile textile widely used in the fashion industry. It is made from cellulose fibers derived from beech tree pulp. This fabric is often blended with other fibers like cotton or spandex to enhance its properties.

One of the key advantages of this fabric is its exceptional softness, which rivals that of natural fibers like silk and cashmere.

It has a smooth surface and drapes well, making it an ideal choice for clothing that requires a comfortable and elegant touch.

Properties and Characteristics of Modal Fabrics

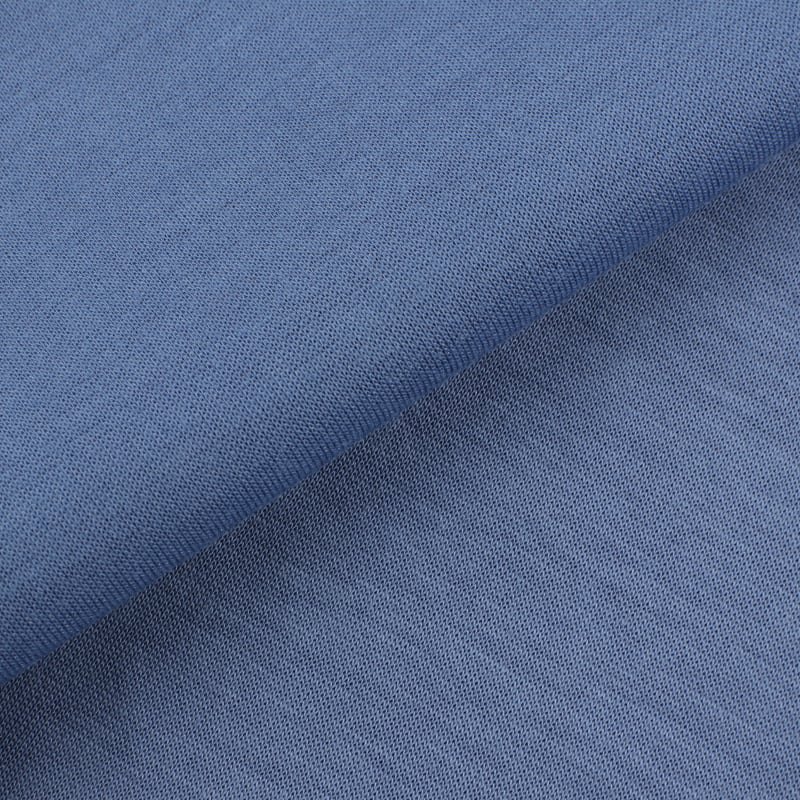

Softness and Drape

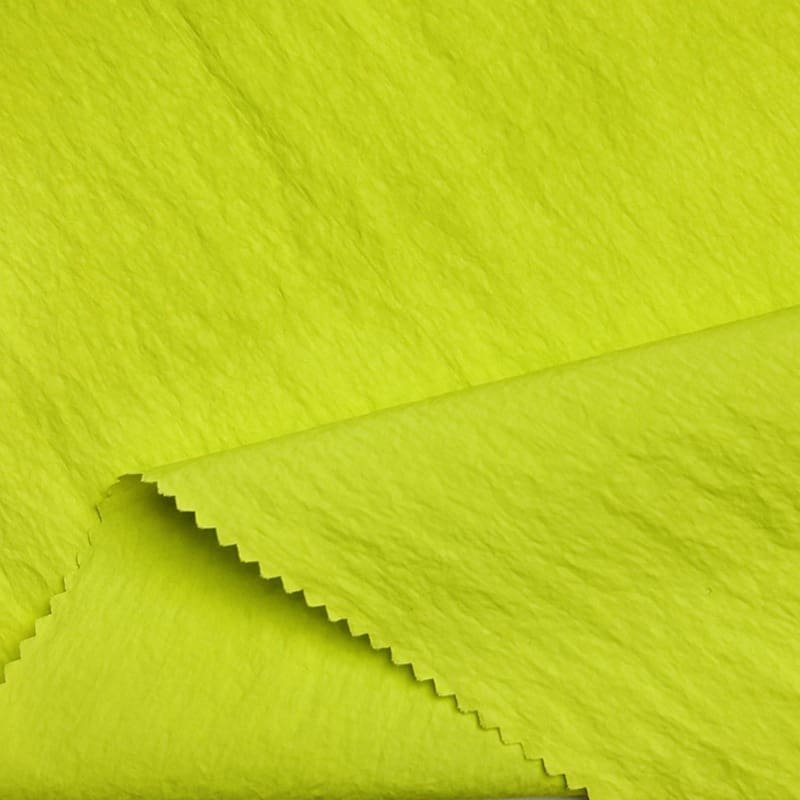

Modal textiles have a smooth and silky texture, providing a comfortable and gentle feel to the skin. The fabric also has an excellent drape, meaning it flows and hangs gracefully, enhancing the garment’s elegance.

Color Retention

Modal textiles have great color retention, making it perfect for clothing that requires long-lasting color intensity even after repeated washing and sunlight exposure. This ensures garment longevity and visual appeal.

Moisture Absorption

Modal textiles effectively absorb moisture, keeping the wearer dry and comfortable. It absorbs 50% more water than cotton, making it ideal for activewear, sportswear, and undergarments that require moisture management.

Durability

Modal textiles are soft yet durable, resistant to wear and tear, and maintain their shape even after stretching and pulling. It also resists shrinking, pilling, and fading, making it ideal for long-lasting garments that can withstand regular use and washing.

It is important to note that while this fabric possesses certain properties, the specific manufacturing process, fiber blends, and finishing treatments applied to it can also affect its final characteristics.

Nevertheless, the fabric is a versatile and highly sought-after fabric in the fashion industry.

How Modal Fabrics Are Made

Modal fabrics are made from cellulose fibers derived from beech tree pulp. The wood from these trees is chipped and processed to obtain cellulose fibers, which are the basis for these fabrics.

The production process involves several steps to convert raw materials into the final fabric.

Production Process of Modal Textiles

By understanding these steps, designers and clothing brands can make informed choices about these fabrics for their creations, ensuring quality and sustainability.

Uses and Applications of Modal Fabrics

Clothing

Modal’s softness, durability, and color retention make it ideal for use in clothing such as shirts, dresses, skirts, underwear, and activewear.

This fabric’s versatility and desirable qualities make it a popular option for various clothing applications, ensuring comfort and style for the wearer.

Home Textiles

Modal textiles are versatile and perfect for home textiles, such as bedding, towels, bathrobes, curtains, upholstery, table linens, and decorative pillows.

It is well-liked due to its softness, durability, and moisture absorption. Modal bedding provides a comfortable sleep surface, while towels offer absorbency and a plush feel.

Modal textiles enhance comfort, aesthetics, and functionality in home textiles, making them a popular choice for bedding, upholstery, and decorative items.

Industrial Applications

Modal fabrics have many industrial applications due to their practical properties. Its strength and durability make it suitable for reusable packaging materials and industrial bags.

It is also useful in moisture management fabrics, protective clothing, and specialized textiles. This fabric is soft and absorbent, making it suitable for cleaning and wiping in industries like automotive, electronics, and optics.

Advantages and Disadvantages of Modal Fabrics

Advantages

- Eco-Friendly: Modal fabrics are made from renewable beechwood trees, making it a more sustainable option than many synthetic fabrics.

- Versatile: Modal fabric’s softness and durability make it suitable for a wide range of applications, from clothing to home textiles to industrial uses.

- Comfortable: Modal fabrics are soft, breathable, and moisture-absorbent, making it comfortable to wear and use.

- Easy to Care For: Modal fabrics are easy to care for and can be machine washed and tumble-dried.

Disadvantages

- Chemical Treatment: Modal fabrics are made using a chemical treatment process that can be harmful to the environment if not properly managed.

- Shrinkage: Modal fabrics are prone to shrinkage if not washed and dried properly.

- Wrinkling: It is prone to wrinkling, which can require ironing or steaming to remove.

- Price: Modal fabrics can be more expensive than other natural fibers like cotton or linen.

Conclusion

Modal fabrics offer a luxurious, soft, and comfortable experience. This fabric is a game-changer in fashion with its luxurious feel and versatile benefits.

However, care requirements and environmental impacts should be considered. Modal fabrics combine luxury, comfort, and sustainability, making them a top choice for conscious style.