Developed in a lab, nylon is a strong fabric that can withstand rubbing, chemicals, and water. Many businesses use it because it is so intense yet lightweight. In fashion, it is a popular option for outdoor equipment, luggage, and sportswear.

Wallace Carothers, a chemist for DuPont, created nylon fabric in the 1930s. It was later used as a replacement for silk in stockings during World War II.

When it comes to clothing, nylon fibers have several advantages, including their elasticity, lightness, lustrous appearance, and ease of cleaning.

Due to its advancements, nylon became a vital part of the textile industry.

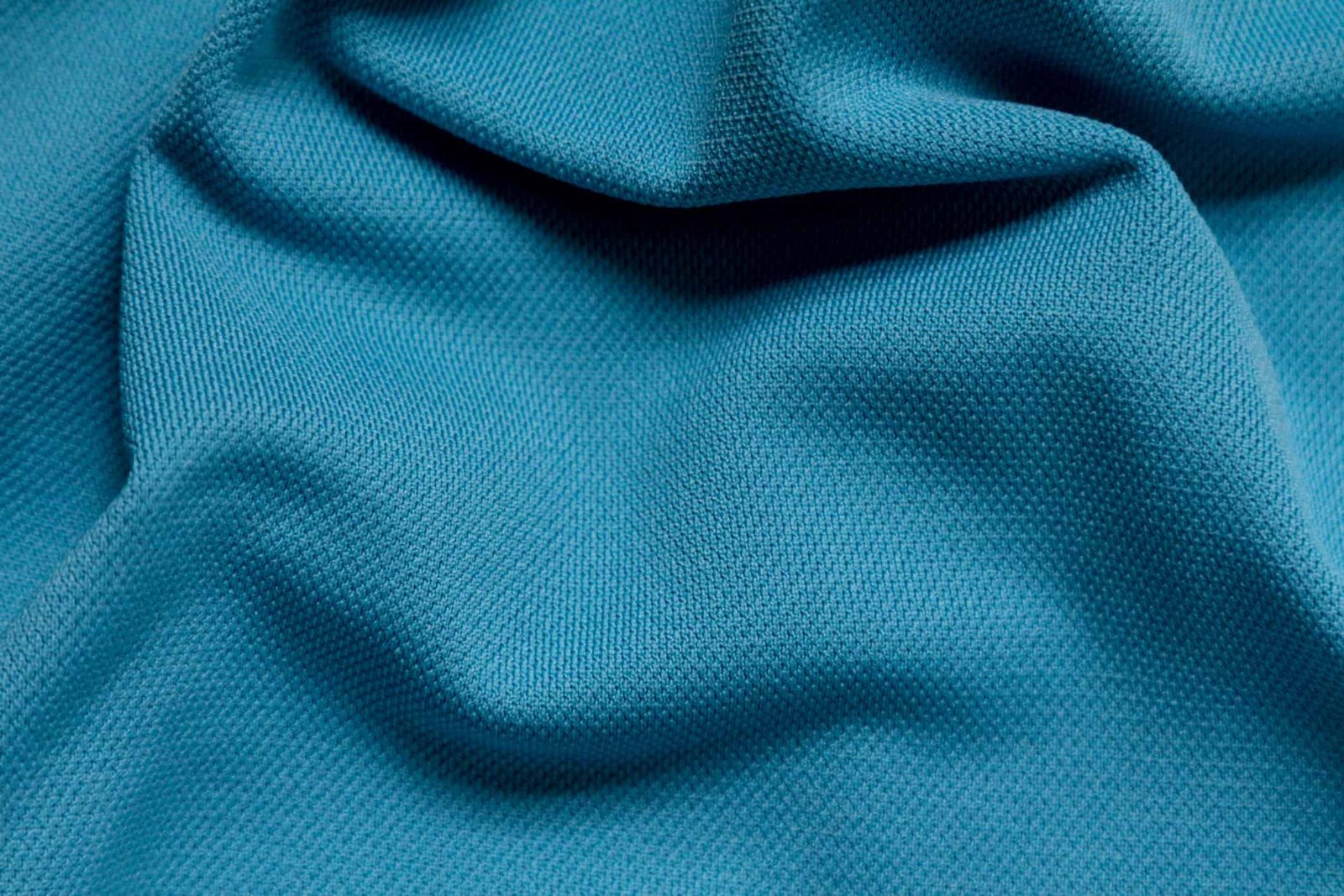

What Is Nylon Fabric?

Nylon is a synthetic material that was introduced as a replacement for silk, which was scarce at the time.

Nylon can stretch and bend without easily breaking. Bugs, chemicals, or mold do not damage it. Nylon is typically used to make clothes, bags, ropes, and car parts.

Additionally, fabrics made of nylon are resistant to heat, chemicals, and abrasion. Because of its various qualities, nylon textiles became popular. It soon found its way into other textile applications.

Properties of Nylon Fabrics

Nylon fabrics are used in many different fields because it has a lot of good qualities. Some of the distinctive characteristics of nylon textile include:

- Strength

- Durability

- Resistance to abrasion

- Lightweight

- Moisture resistance

- Easy to care for.

What Are The Different Types Of Nylon Materials?

There are many different types of nylon, which can be used for a variety of things. Primarily used to make ropes, fishing lines, carpets, tire cords, and parachutes. However, nylon found a way into fashion.

To choose the right nylon cloth for your project, it’s important to know each type available:

Nylon 6,6

This nylon is the most common type of fabric made from hexamethylene diamine and adipic acid. It is waterproof by nature, making it a popular choice for swimwear.

Nylon 6,6 is also good for outdoor gear like tents, backpacks, and sleeping bags due to its water and heat-resistant nature.

Nylon 6

Caprolactam is the material used to create a durable nylon 6 fabric. Nylon 6 is lightweight yet tough, making it perfect for high-impact and stress-resistance applications.

Nylon 6 makes thin and comfy threads for breathable apparel. It is suitable for activewear and undergarments because of its moisture-wicking properties. Additionally, its strength and durability make it ideal for bags and outdoor equipment.

Nylon 6,10

Nylon 6,10 fabric is made by combining hexamethylene diamine and sebacic acid. It is very strong, doesn’t rub much, and can withstand chemicals and abrasion.

People use it in cars, electronics, and sports gear. It’s not great for clothing because it’s rough and can melt at high temperatures. Still, it can work in special clothing for hazardous jobs or the military.

Nylon 4,6

Nylon 4,6 is really strong and can take heat and chemicals well. It is used to make car parts, electrical items, machines, and fibers/films for safety gear and medical devices.

It feels rough and isn’t comfortable to wear on the skin like other nylons. People don’t use Nylon 4,6 as much for clothing.

Nylon 12

This nylon fabric is flexible and has low moisture absorption. It’s a popular choice for electrical cable insulation and tubing.

Nylon 12 is not often used alone in clothing because of its special qualities. But it can be used in specific clothing types, like protective gear for workers in dangerous places or military uniforms.

What Is Nylon Fabric Made Of?

Nylon fabric is made from a special kind of material called a polymer. This polymer is made by mixing two chemicals: adipic acid and hexamethylenediamine.

A mixture is melted and then forced through a spinneret machine to make this fabric. This machine creates long fibers that can be woven together to create fabric.

The fibers are stretched to make them stronger and then spun into yarn. Different types of nylon textiles feel and look different after treating the thread with chemicals or twisting it.

Although the manufacturing process is complex, it results in a durable and reliable product that is highly valued.

What Is Nylon Fabric Used For?

Various applications use nylon fabric due to its properties and characteristics. Some of the applications of this fabric include:

Clothing and apparel

Nylon fabric’s tough and resilient nature makes it an ideal choice for clothing items. This fabric is stretchy and can fit well on the body. This is why it’s often used for swimwear, hosiery, and lingerie.

Industrial uses

The toughness and strength of nylon textiles make them ideal for industrial products. Conveyor belts, ropes, and safety harnesses are some of the industrial products that can be made using this fabric.

Outdoor gear

Nylon fabric can resist moisture. It is an excellent choice for creating outdoor gear like tents, backpacks, and sleeping bags.

Upholstery and home furnishings

Nylon textile is suitable for upholstery because it is durable and resistant to wear and tear. You can use this fabric to make both carpets and sofa covers.

Luggage and bags

Nylon is resilient and resists water damage well. That’s why it’s an excellent choice for making luggage and bags. You can get nylon bags in many styles, like backpacks, duffel bags, suitcases, and tote bags.

Advantages and Disadvantages of Nylon Fabrics

Nylon fabrics are used in various industries for its strength and durability. Here are the pros and cons of nylon fabric and how they can impact its use in different applications.

Advantages of nylon fabrics

Nylon textiles have several advantages that make them ideal for many applications. These include:

- durability

- lightweight nature

- water-resistance

- and versatility.

Nylon fabric is strong and can be used for outdoor clothes and gear because it doesn’t easily get damaged. It is very light and easy to carry around, and it can also stop water from getting in.

It is perfect for raincoats, umbrellas, and other items that need to keep you dry.

This fabric can be used for a variety of applications, including clothing, backpacks, and tents.

It is easy to clean and dries quickly, making it a great choice for outdoor gear and clothing. Its low moisture absorbency also means that it is less likely to develop mold or mildew.

Disadvantages of nylon fabric

Nylon fabric is useful in many ways. If you plan on using nylon fabric, here are some of the cons that you have to be aware of:

Nonbiodegradable

Nylon textiles take a long time to decompose, so it’s not biodegradable. That is why nylon textiles can cause pollution and environmental damage.

It can melt or burn.

Nylon fabrics are flammable and can melt or burn when exposed to heat. This can pose a safety risk for clothing or industrial products.

Prone to static electricity buildup

Nylon clothes can create static electricity that causes discomfort due to shocks or clinginess. To prevent it, anti-static treatments can be applied.

Skin irritation.

It can cause skin irritation in some people with sensitive skin, especially those with eczema. It has the ability to trap moisture and heat against the skin.

Susceptible to pilling.

Nylon fabrics can be prone to pilling. It is the formation of small balls or fibers on the material’s surface. This can reduce the durability of the fabric over time.

It can absorb moisture.

Nylon fabrics can absorb moisture. It can make it uncomfortable to wear or use in specific environments. This can also contribute to bacteria or mold growth in some applications.

Conclusion

Nylon is tough, long-lasting, and water-resistant and are still popular for making apparel. However, as people care more about the environment, sustainable options are used.

Nylon’s future is uncertain as sustainability gains importance. Collaboration and eco-friendly processes can address the environmental concerns of this fabric.

Nylon fabric manufacturers should evolve and meet market needs with sustainable solutions.