Source: Pexels

Polo shirt manufacturing originally started in India and came from the game polo. Normally, it is made of cotton and polyester, making it perfect for games like polo.

Cotton and polyester are the most commonly used fabrics for manufacturing polo shirts due to their durability. Moreover, because of the comfort and durability that polo shirts offer; players love to wear them during their games.

To make polo shirts unique, polo shirt manufacturers add collars to them. That unique trait of polo shirts makes them perfect for casual and formal events.

Despite its unique characteristics, many still consider polo shirts and golf shirts as one. To explain, polo shirts are more fitted and may or may not have short or long sleeves. On the other hand, a golf shirt is ordinarily loose and has shorter sleeves, perfect for moving around on the golf field.

If you are planning on having your brand that offers polo shirts but have limited knowledge about it. This article is perfect for you!

Understanding Polo Shirts Manufacturing

Source: Vecteezy

You can depend on polo shirts for comfort and style. Further, there are different types of polo shirts that the polo shirt manufacturing industry offers.

Polo shirts sometimes have minimal designs on the chest. However, most of the time, polo shirts come without graphic or embroidered designs. This trait of the polo made it suitable as professional attire.

How To Design Perfect Polo Shirts? The Procedures And Types

Source: Vecteezy

Various polo shirts are already on the market. The design and fabric dictate the price. If you plan to have your brand, you have to outsmart those established brands of polo shirts. Think of something that they don’t have. Try to build your image and style.

What are the steps for designing polo shirts?

Before establishing your brand, you need to have the best designs, and there are polo shirt designers to help you with that. Moreover, to give you a starting point, here are the steps for designing polo shirts.

1. Establish Your Objectives

Start creating the polo shirt design only after setting your manufacturing objectives. Since your objectives will determine what type of polo shirt your manufacturer will make, it’s important to assess yourself. To aid you in that, try to ask yourself these questions:

- “What type of polo shirts suit my body?”

- “How many times can I wear it?”

- “Will it be paired with my skirts, pants, or trousers?”

- “When can I wear it?”

- “Can I find that design on the market?”

Remember that your objectives will guide you in choosing the design that suits your polo shirt. Which is why you have to take it seriously.

2. Apply Your Imagination

The next step is where you need to put your imagination and ideas into one. Since you want to give the best design to your manufacturer, you have to dig deeper into the design part.

You may consider answering these questions to help you decide what designs you’ll put on your polo shirt.

- “What color will highlight my skin tone?”

- “What kind of design matches my personality?”

- “Is this design already available on the market?”

Why not incorporate your design with your personality to make it unique? Try to think about something similar to your name, your hobbies, or even what you dream about.

3. Do Your Sketch

Doing your sketch is a crucial step. Your sketch will serve as the blueprint that will guide the polo shirt manufacturer.

4. Choose The Fabric

The selection of the best fabric for your polo shirt should be done once your sketch is entirely completed. Remember that fabric is crucial in making a polo shirt. You must therefore choose the best fabric to use.

In choosing the fabric you’ll use for your polo shirt, you need to consider the skin types of the wearer.

Further, you can always ask for your manufacturer’s ideas. Remember that they are more knowledgeable when it comes to the fabrics used in polo shirt manufacturing. Which is why they can give you options when it comes to fabrics.

5. Decide Who’s Designing Your Polo Shirt

Designing polo shirts is much work; you must have the necessary knowledge and tools to accomplish it effectively. If so, why not consult those who know it?

Further, here are the platforms where you can find polo shirt manufacturer experts or polo shirt designers:

- Fiverr

- People Per Hour

Design your polo shirts with a customizable template

Technological innovation could help you elevate your designs through the use of customizable templates. Using a customizable template, you can design wherever you are. Once you gather the ideas for your polo shirt design, you can now send it to your polo shirt manufacturer.

Tips for designing polo shirts

To make your polo shirt more interesting, the following are some tips for designing your polo shirt:

1. Decide On The Placement

The placement of your design is important to consider since it aims to highlight the design itself. Polo shirt manufacturers prefer to put the design on the left side of the chest and in the sleeve part. Additionally, manufacturers also consider the nape part of the polo shirt for logo placement.

Moreover, if you are not confident with the placement of your design, your polo shirt manufacturer will do the job.

2. Pick The Color For Your Polo Shirt

The color of your fabric will depend on your objectives and your skin tone. You have to make sure that your chosen color is suited to your skin. In addition, when selecting the color for your fabric, try to think of an unusual color and add your style to it.

3. Add visuals and graphics

Source: Pinterest

Most polo shirts on the market have graphics and visuals on them; some have embroidered designs, so you can try to combine these two. Further, these details must also be included in your sketch to ensure you have a solid foundation for your polo shirt.

4. Make Use of Typography

Source: Behance

There are instances where a polo shirt has typography on it. Typography for polo shirts comes in minimal or large sizes; sometimes it’s paired with graphics.

Further, polo shirt manufacturers have different ways of putting typography on the polo shirts. Typography can be done through direct-to-garment printing or screen printing.

7 Types of Polo Shirts

Several types of polo shirts are available on the market. For you to become a trend maker, think of the most uncommon polo shirt on the market. It is necessary to ensure that your brand can stand out from the numerous designs that saturate the market.

Moreover, you may consider these seven types of polo shirts for your first polo shirt:

1. Classic Polo

Source: Pinterest

The classic polo shirt is made up of cotton fabric and has a collar that perfectly hugs the neckline. It has a buttoned placket for extra tightness, and it has shorter sleeves. Normally, this can be seen during casual events.

2. Short Sleeve Polo

Source: Pinterest

Short-sleeved polo shirts have short sleeves and are made up of cotton, perfect for summer. Normally, it comes in various colors that can be paired with shorts and pants.

3. Long Sleeve Polo

Source: Pinterest

The length of its sleeves makes it unique from the others. Long-sleeve polo shirts offer a classy vibe due to their long sleeves. In addition, the sleeves protect and keep the wearer warm and covered making it perfect for winter.

4. Rugby Polo

Source: Robb Report

Rugby polo shirts are used for rugby games. It is made up of cotton and polyester fabric, making it durable. Typically, people also wear this polo shirt for casual occasions; they mostly pair it with pants.

5. Golf Polo

Source: Pinterest

The polo shirt for golf proves that it can be useful in other sports as well. The reason why golfers typically wear a golf polo shirt is because of its stylish appearance and its suitability for playing.

Additionally, this type of polo shirt is made out of a very light material instead of being bulky like rugby ones.

6. Tennis Polo

Source: Pinterest

One more polo shirt for sports is a tennis polo shirt. It is made from light textiles to help the wearer feel more comfortable while moving. In addition, tennis polo shirts are appropriate for casual events because they are multifunctional as well as classic.

7. Pocket Polo Shirt

Source: Pinterest

Among all kinds of polo shirts, there is only one type with a pocket–pocket polo shirt. Normally, the pocket is located on the left side of the chest, making it stylish and functional. Further, The pocket polo shirt is a clear representation of smart casual wear in the fashion industry.

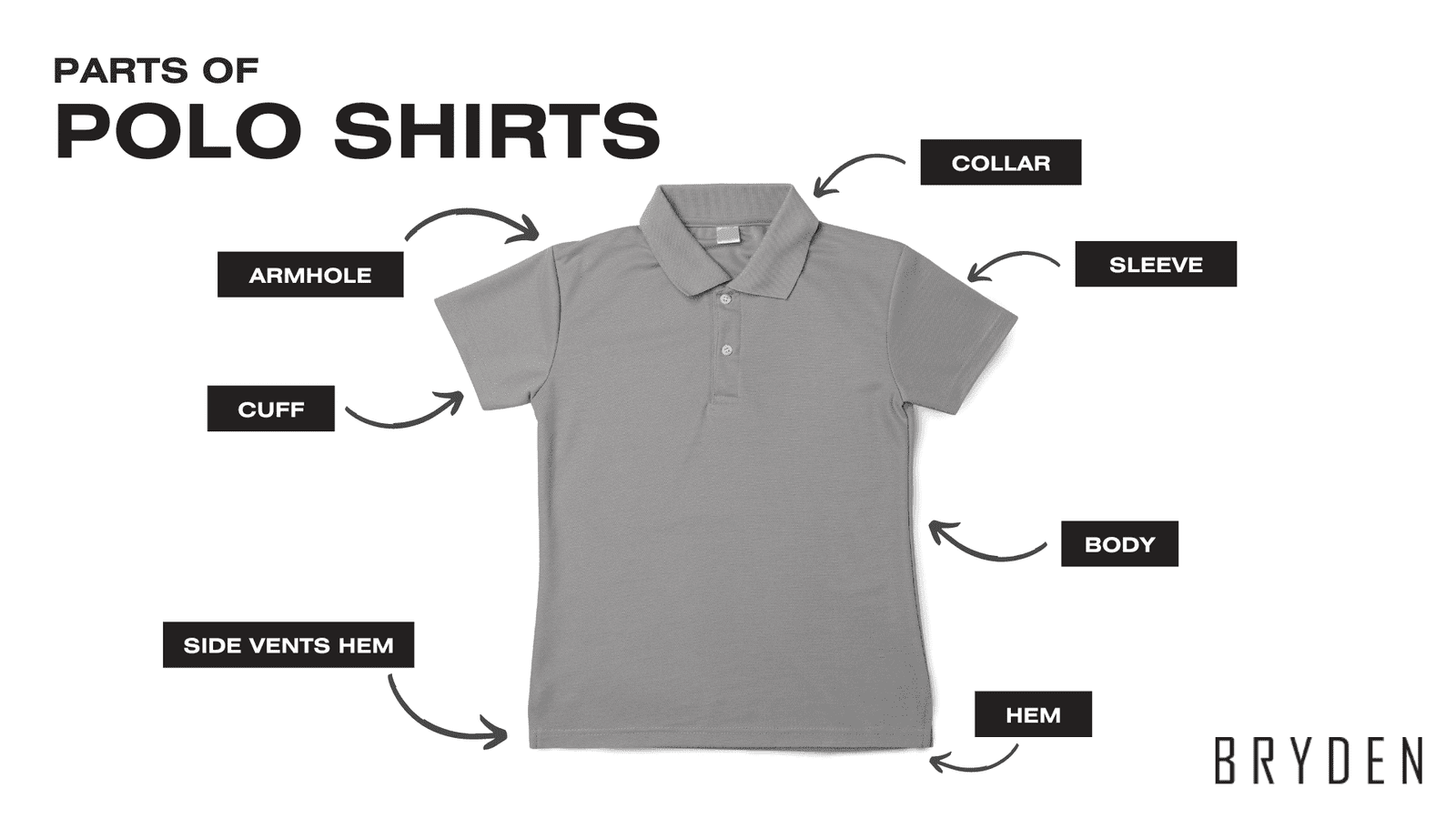

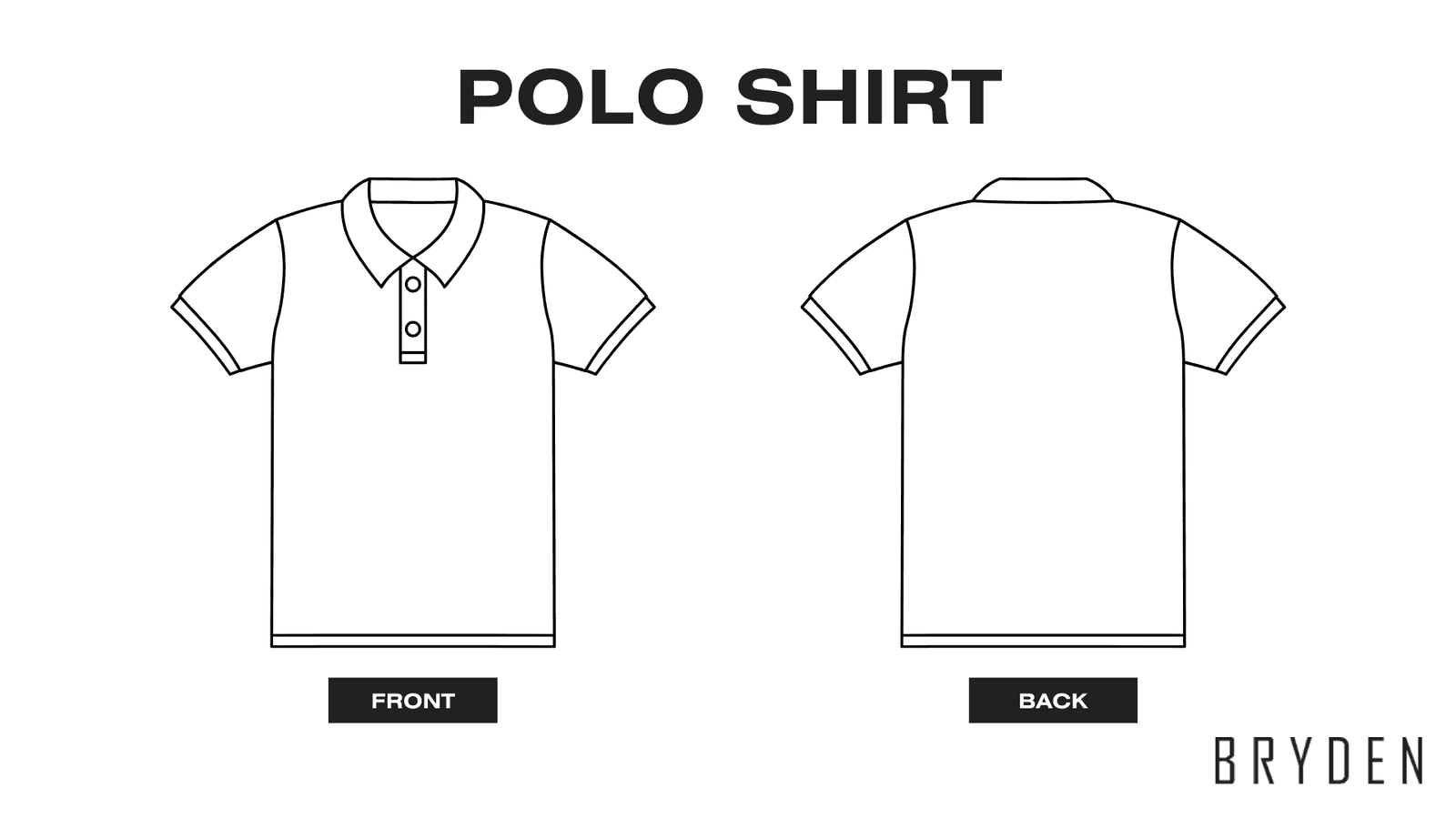

Anatomy Of Polo Shirts

Every part of the polo shirt has its function. When it comes to designing, you have to include all the parts necessary for the polo shirt. Additionally, you can add other parts based on your preferred designs.

Further, here are the parts of a polo shirt:

- Collar

This is a part of a polo shirt that fastens around the neck.

- Armhole

This part is the opening part for the arms.

- Sleeve

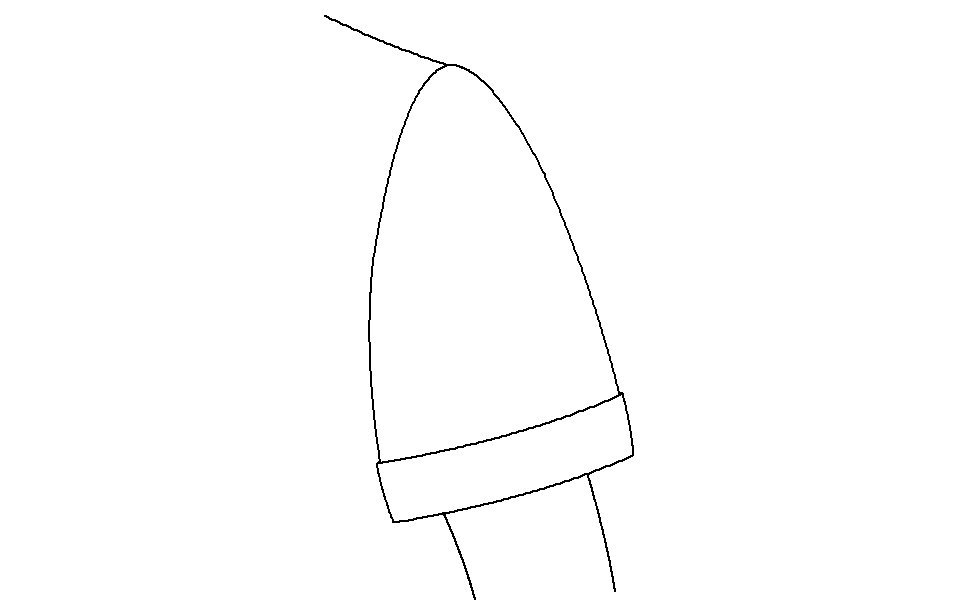

The part that covers the arm and shoulder.

- Placket

This is the slit or opening in the front body of a polo shirt. It is also where the buttons are placed.

- Cuff

This is the end part of the sleeve.

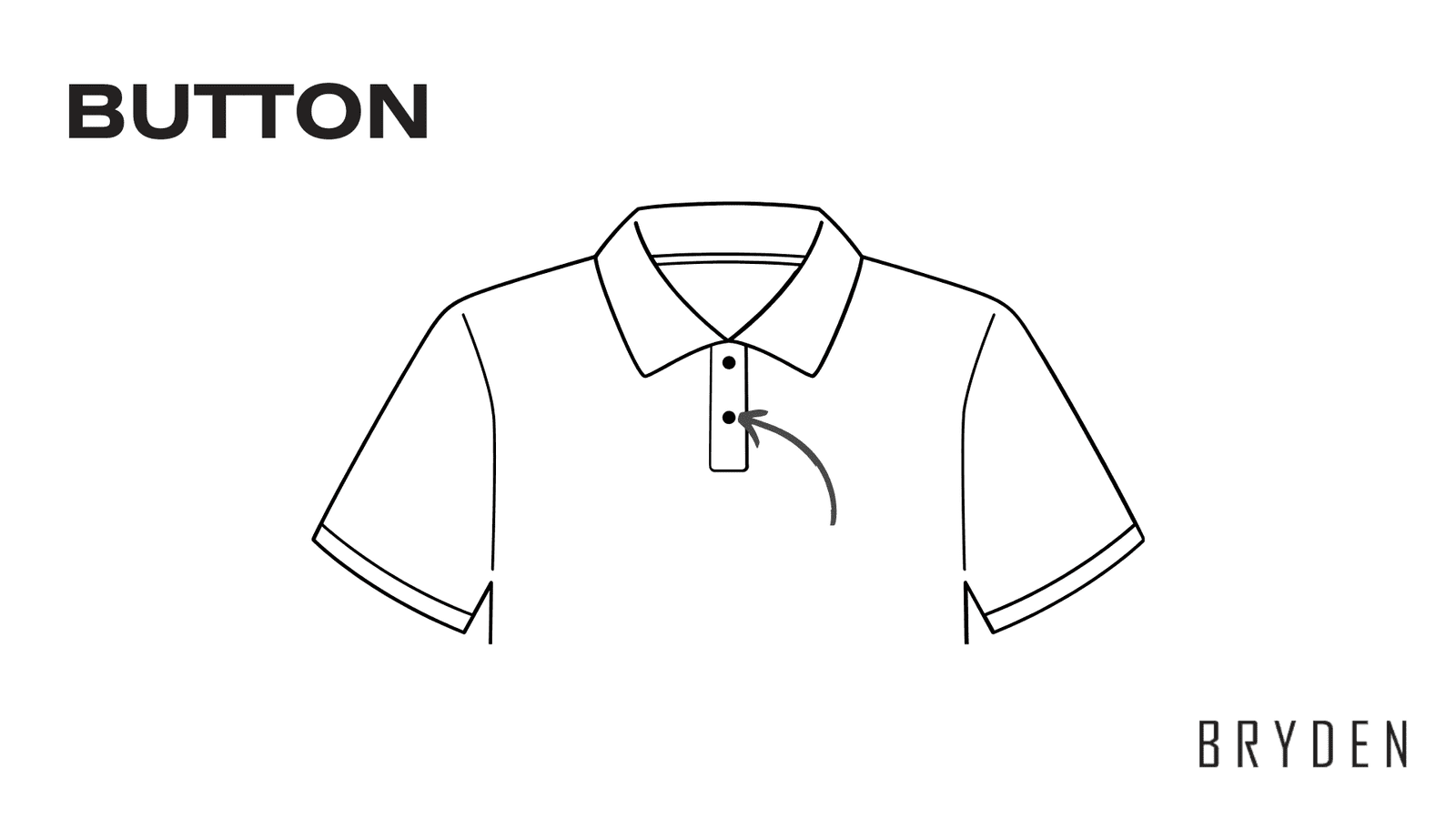

- Button

This is the one that fastens the slit of the front body.

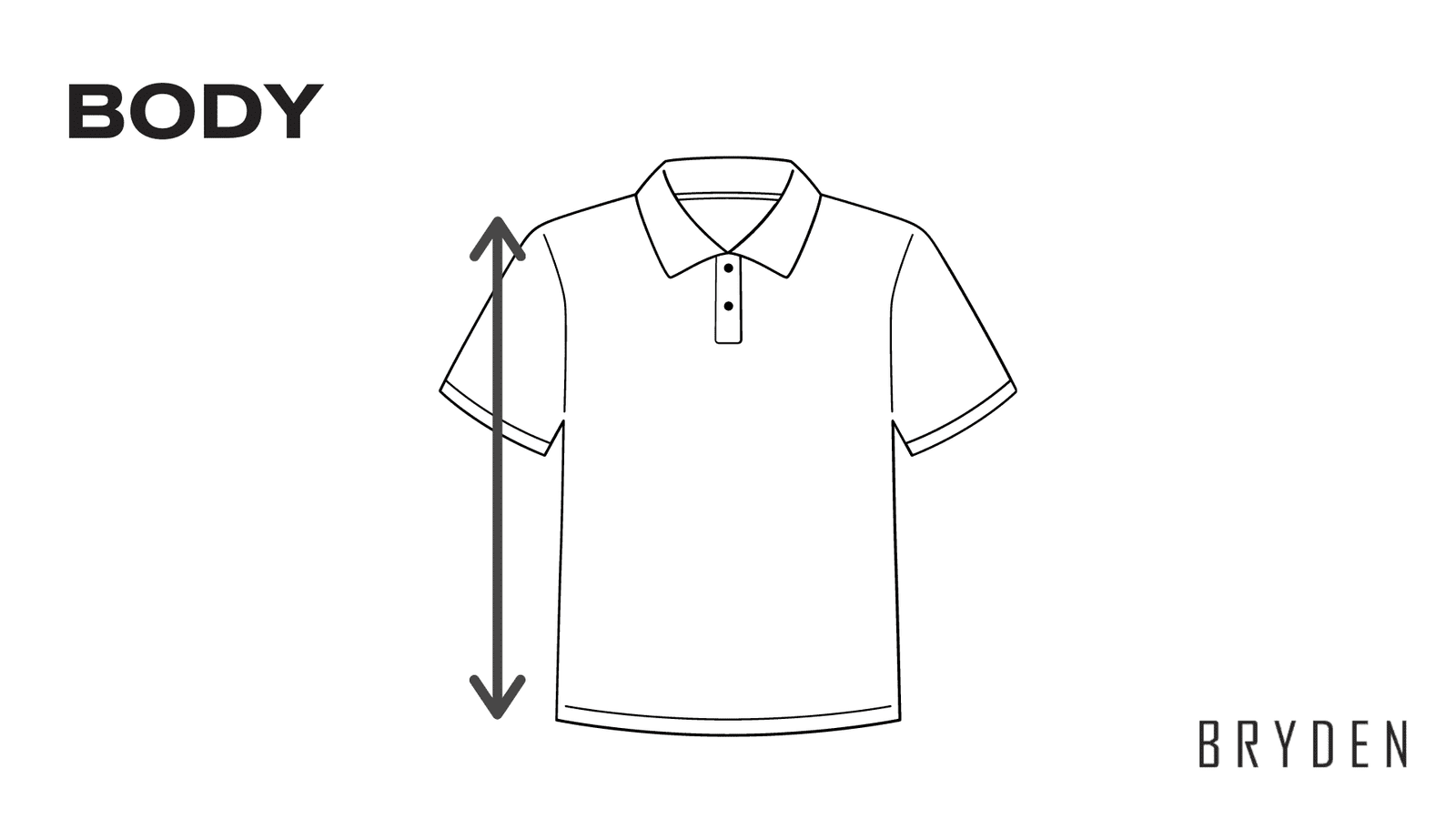

- Body

This is where the designs are placed, it also indicates the front and back bodies.

- Hem

This is the border of the body of the polo shirt.

Polo shirts may or may not have pockets.

Remember that in making polo shirts, your pattern as well as your design must accurately match each other.

What fabric is best for polo shirts?

Source: Contrado

Polo shirt manufacturers always consider the type of fabric when it comes to making a polo shirt. Manufacturers use the fabric as their canvas and your design will make it interesting.

Moreover, some fabrics might not suit your skin condition. Therefore, it is important to ask your manufacturer which fabric suits you.

1. Cotton

Polo shirt manufacturers use cotton because it is soft and durable. Manufacturers often choose between upland cotton, organic cotton, or pima cotton for the creation of polo shirts.

2. Polyester

To make polo shirts that do not easily shrink, polo shirt manufacturers choose polyester. Polyester is best for outdoor polo shirts like tennis polo shirts or rugby polo shirts due to its durable synthetic fibers.

3. A combination of polyester and cotton

If you want to have the breathability of cotton while having the durability of polyester, this is for you. The combination of polyester and cotton has a ratio of 50/50 or 65/35. It will depend on what you want.

Moreover, polo shirt manufacturing had two ways to enhance the strength and increase the weight of the fabric. These are through pique knit and jersey knit.

How Does The Polo Shirts Manufacturing Industry Make Patterns?

Source: LinkedIn

The polo shirt manufacturing industry provides various types of polo shirts with and without typography or visuals. To emphasize this, the role of the pattern is essential for the success of the manufacturing process. That is why you have to hire the right polo shirt manufacturer to help you.

The following are the steps in making a pattern for polo shorts:

- Sketch the design of the desired polo shirts.

- Take accurate body measurements.

- Prepare the materials for making patterns, such as the marking tools, illustration, and tape measure.

- Using the marking tools, apply the measurements to the illustration board or cardboard.

- Ensure the measurements are accurate using the measuring tape.

What is pattern making?

It takes a lot of effort and time to create a pattern to make a perfect polo shirt. In this case, you need to have the best polo shirt manufacturers. Your pattern is the blueprint for the creation of the polo shirt, so it must be stable and accurate.

With that, here are the steps for pattern-making of polo shirt:

1. Sketch Your Design

One of the keys to a perfect pattern is the sketch. Your sketch must include the type of polo shirt you want to make, the designs and the color of it. Further, make sure that your sketch is durable since you’ll need it for quite some time.

One of the keys to a perfect pattern is the sketch. Your sketch must include the type of polo shirt you want to make, the designs and the color of it. Further, make sure that your sketch is durable since you’ll need it for quite some time.

2. Make Accurate Measurements

Another factor that contributes to the successful manufacturing of polo shirts is accurate measurements. You have to take the measurements accurately, particularly in those areas that are delicate. Areas such as the waist, armhole, collar, chest, sleeve, and the back and front.

Measurement for waist

Source: NMUS

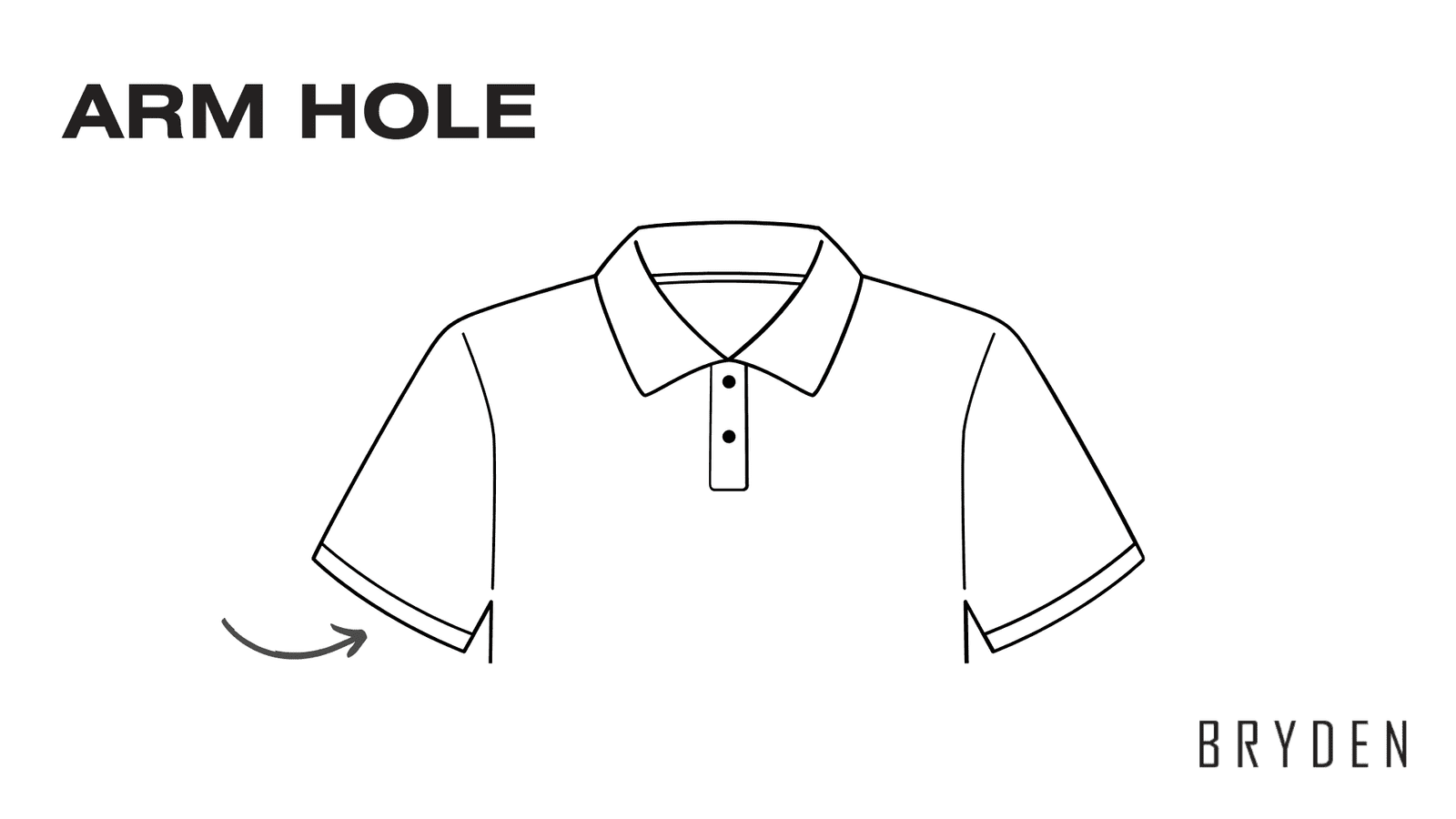

Measurement for armhole

Source: Brydealo Factory

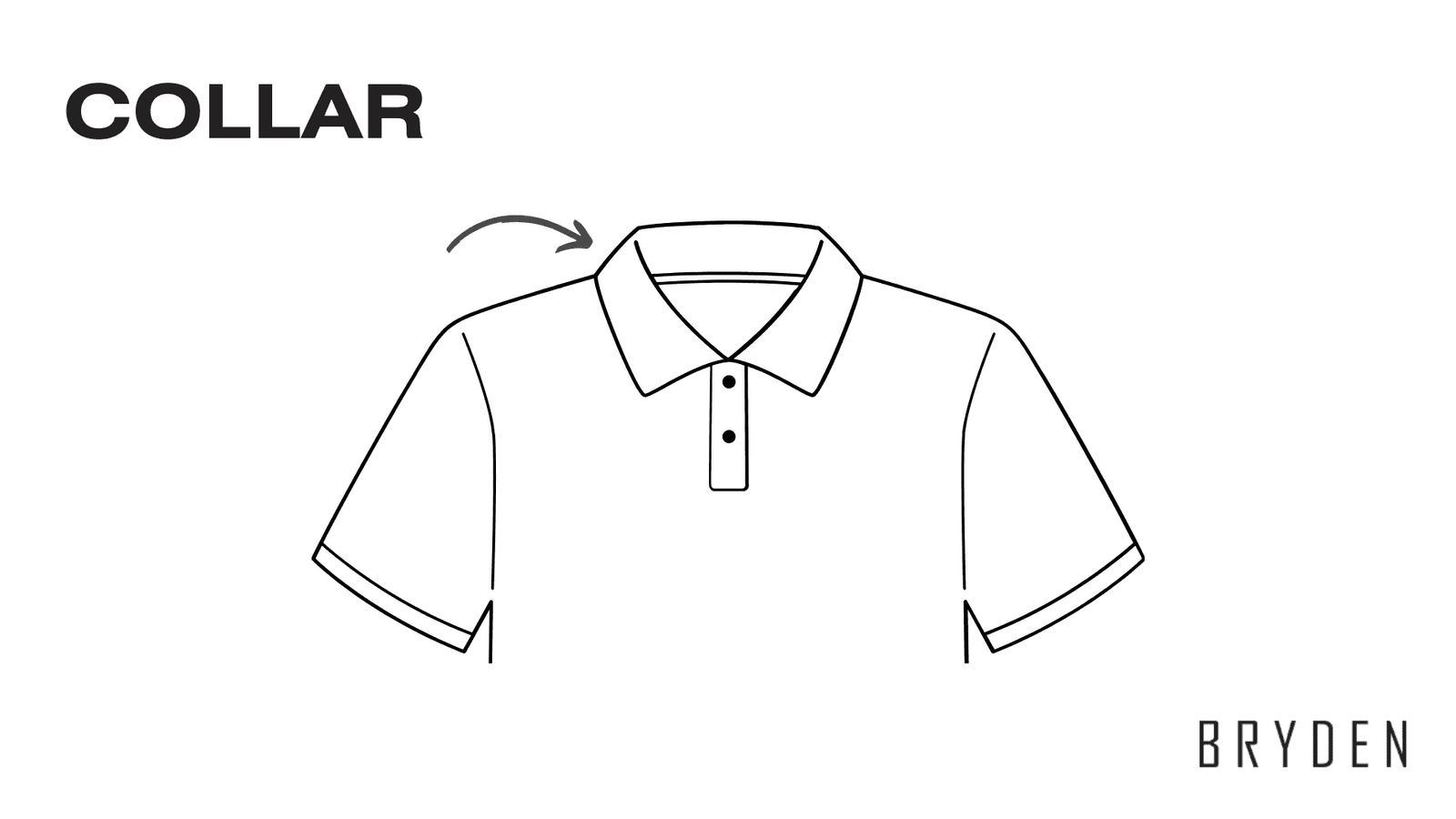

Measurement for collar

Source: Tapered Menswear

Measurement for chest

Source: Tapered Menswear

Measurement for sleeve

Source: Pinterest

Measurements for back and front

Remember that we want to avoid getting inaccurate measurements, so coordinate with your polo shirt manufacturer to take your measurements accurately.

Remember that we want to avoid getting inaccurate measurements, so coordinate with your polo shirt manufacturer to take your measurements accurately.

3. Decide How To Make The Pattern

Polo shirt manufacturers use two methods in making patterns and these are the following:

Pattern Drafting

Source: Sewport

This is a method for creating basic blocks for your design based on specific body parts such as the waist, armhole, chest, and shoulder.

Draping

Source: Sew Mega

This technique is a 3D technique that creates patterns by placing the fabric directly on the human body. It allows the manipulation of different fabrics to achieve different effects.

4. Add Details

Source: AllFreeSewing (Notches)

Source: Craftsy (Curves)

The pattern must be accurate and to do that, the pattern must have curves and notches.

5. Digitize Your Pattern

Once you have your pattern, you can reproduce it through an online copy. You can add a description, name, and price to it since you can sell it to other aspiring entrepreneurs.

Remember that the pattern must be accurate in any aspect. The pattern is the blueprint of the whole manufacturing process, which is why it has to be perfect.

Marking Tips for Cutting Patterns on Fabric

Source: Blueprints For Sewing

To make the polo shirt pattern accurate, it has to be marked properly. Hence, these are the marking tips for cutting patterns on fabric

- Lay the fabric on a flat surface.

- Put the pattern on top of the fabric and secure it using pins.

- Use marking tools such as tailor’s chalk and tracing wheel to trace the pattern into the fabric.

- Add seam allowances. Further, the standard seam allowance for polo shirts and similar garments is 1.5 cm.

Moreover, polo shirt manufacturers follow a measurement chart for manufacturing polo shirts.

- The chest must be 100 cm and half of it must be 50 cm.

- For the armholes, both must be equal to 40 cm with 2 cm sewing allowance.

- The standard length of sleeve for polo shirts is 25 cm but this depends on the type of polo shirt.

- Collar length is 48 cm with 6 cm height and 2 cm sewing allowance.

- The body side seams must have an equal allowance of 3 cm.

How Do Polo Shirts Manufacturers Cut And Sew The Fabric Pieces?

Source: Pexels

The cutting process is delicate, like pattern making. This process requires focus and sharp shears to avoid miscut. Furthermore, polo shirts manufacturers use sharp shears to avoid damaging the fabric. As delicate as it is, the cutting process is one of the ways to oversee the entireness of the sketch.

How do I cut polo shirts?

Polo shirt manufacturers use one method to cut the fabric for polo shirts, and this is through cutting the pieces.

Cutting The Pieces

Polo shirts have a few parts that can be cut separately. Since polo shirts aren’t like the other garments that have various styles with different parts. The manufacturer can cut the fabric through one method, regardless of its type. Further, polo shirt manufacturers separately cut the following parts: Sleeve, Collar, Front, and back

Sleeve

Source: The Measuring Tape

Pin the sleeve pattern to the fabric and cut along the sewing allowance of armholes.

Collar

Source: Vecteezy

Take the neckline measurement, estimate the length and width of the collar and then mark it and cut it horizontally.

Front and Back

Source: Professor Pincushion

Pin the front and back pattern to the fabric that includes the chest, shoulder, neckline, and cut along the sewing allowance.

Sewing the Polo Shirt

Source: Art News

This step is essential for your polo shirt manufacturing; this is where all your efforts can be seen.

The polo shirt manufacturers commonly use two types of sewing machines. These are the overlock sewing machine and the industrial sewing machine. Moreover, according to manufacturers, both machines can be used in one polo shirt.

Polo shirt manufacturers have the procedures for sewing a polo shirt, these are the following:

What Are The Different Types Of Seams For Polo Shirts?

According to polo shirt manufacturers, these are the most commonly used seams in manufacturing polo shirts:

1. Lapped Seam

Source: Things for Boys

Lapped seam is a type of seam for non-fraying fabrics like cotton. This seam involves the process of overlapping the edges of the fabric, making it more durable and preventing the fabric from fraying.

2. Flat-felled seam

Source: Itch to Stitch

A flat-felled seam is typically used for strengthening the edges of the fabric pieces. This can be used for the color and the hemline of your polo shirt.

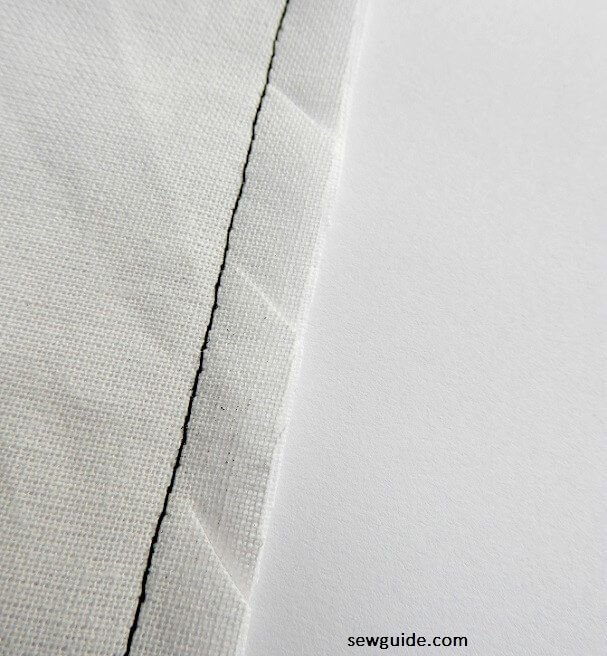

3. Plain seam

Source: SewGuide

The most basic type of seam is a plain seam, which involves the attachment of two fabric pieces. This seam is used for lightweight fabric such as cotton. Typically, this can be used for classic polo shirts.

What Are The Measurement Points For Polo Shirts?

Source: I’m So Fancy

Accurate measurements are important to ensure that the polo shirt fits your size. Normally, to ensure the accuracy of the measurements, polo shirt manufacturers use the standard size guide for polo shirts.

- People who have a chest measurement of 98 cm, waist measurement of 92 cm, and back length of 72 cm are extra small (XS) and size 36.

- People who have chest measurements of 104 cm, a waist measurement of 98 cm, and a back length of 72 cm are small (S) and size 37/38.

- People who have a chest measurement of 110 cm, a waist measurement of 104 cm, and back length of 74 cm are medium (M) and size 39/40.

- People who have a chest measurement of 116 cm, waist measurement of 110 cm, and back length of 76 cm are large (L) and size 41/42.

- People who have a chest measurement of 124 cm, waist measurement of 120 cm, and back length of 78 cm are extra large (XL) and size 43/44.

- People who have a chest measurement of 132 cm, waist measurement of 132 cm, back length of 80 cm are 2XL and size 45/46.

- People who have chest measurements of 140 cm, waist measurements of 140 cm, and back lengths of 80 cm are 3XL and size 47/48.

- People who have a chest measurement of 148 cm, waist measurement of 148 cm, back length of 82 cm are 4XL and size 49/50.

- People who have a chest measurements of 156 cm, waist measurement of 156 cm, and back length of 82 cm are 5XL and size 51/52.

Moreover, manufacturers follow a list of measurement points that are essential for creating the pattern for polo shirts. These measurement points are:

1. Chest Width

Source: Budd London

Chest width is the measurement across the front of the body from underneath the armpit.

2. Sleeve Length

Source: Tapered Menswear

Measurement from the top of the shoulder until the desired sleeve length.

3. Shoulder to shoulder

Source: Fitness Volt

The measurement was taken from one tip of the shoulder to the tip of the other shoulder.

4. Total Length

Source: A Tailored Suit

Measurement from the top of the shoulder until the desired polo shirt length.

5. Waist

Source: Health times

The distance around the waist, just above the hips.

6. Arm circumference

Source: Solo Abadi

The measurement is around the arm, just below the armpit.

These measurement points will guide the polo shirt manufacturers in taking the measurements for the pattern. Additionally, if you want to add other parts, such as the pocket, you may request it from your manufacturer. Let the polo shirt manufacturers know what your estimated size for the pocket is.

The Art Of Printing For Polo Shirts

The designs for the polo shirt can still be elevated by the following printing techniques:

1. Embroidery

Source: Pinterest

This is a popular printing technique for polo shirts due to its elegant style. This technique uses different colors of thread to put a design logo on the fabric. The threads can be stitched using embroidery machines to make the design as detailed as possible.

2. Screen Printing

Source: Pinterest

This technique is popular, particularly for customized polo shirts. This method uses a mesh screen, ink, and rubber blade to imprint the design into the fabric.

3. Direct To Garment (DTG) Printing

Source: Pinterest

One of the most convenient ways to transfer the design into the fabrication process is through DTG. This technique uses a specialized printing machine to transfer the design. Usually, this is used by manufacturers who manufacture bulk polo shirts to have faster production.

What Are The Different Types Of Garment Washing For Polo Shirts?

Source: Vanish

Polo shirt manufacturers encourage their clients to learn how to properly wash polo shirts. Remember that by properly washing the polo shirts you can maintain their durability and design.

Here are the 2 types of garment washing you can try to keep your polo shirt as good as new:

1. Garment Wash

A method that uses the natural way of washing. It uses water and detergent and can be done using manual or mechanical processes.

2. Enzyme Wash

This is a method that uses enzymes to soften the fabric and remove the stains as well as the odors. Further, this method cannot fray the fabric since it does not require high temperatures or chemicals.

You can use garment washing as your marketing tool for your brand. Why not add the details on how to wash the polo shirts to your packaging? Remember that you need to make your brand unique, and an informative approach may help you with that.

Fabric Dyeing Technique for Polo Shirts

Source: Pexels

Polo shirt manufacturers try various methods including dyeing to elevate the design of the polo shirts. Further, you can ask your polo shirt manufacturer what type of dyeing method is best suited for your chosen fabric.

Further, to give you an overview, here are the dyeing techniques you may add to your polo shirt:

1. Tie dye

Source: Pinterest

This is a technique that requires manual labor. It uses water, dyes, and rubber bands. You have to use the rubber bands to tie the fabric and eventually pour the dyes. Let the fabric absorb the dye and put it into the water to spread the colors.

2. Ice dye

Source: Pinterest

This technique requires dye and ice. The melting ice is responsible for spreading the dye into the fabric, which will eventually make a pattern.

3. Overdye

Source: ClothesEncounter

This technique uses multiple dye colors to create layering patterns in the fabric. This is perfect if you want to customize your polo shirts. The more layers of dye, the more interesting your polo shirts would be.

Quality Control Measures

Source: Pexels

One of the factors you need to make sure is the quality of your polo shirt. There are various methods polo shirt manufacturers use to ensure that the polo shirts meet the standard quality. Further, you can be involved in those methods so that you have enough knowledge when it comes to quality control.

Sizing and Fitting

The sizing and fitting tests are just some of the quality control tests your polo shirt must undergo. Your polo shirt must also undergo fabric testing, design analysis, and seam inspection.

These quality control measures aim to ensure that your polo shirt is of high quality and can make your brand remarkable.

Of course, you aim to encourage people to buy and patronize the brand you’re going to make. This is why, you must impress them not just when it comes to the design but the quality as well.

Packaging and Branding

Source: Freepik

Unique packaging and branding are important to make your brand shine. Therefore, you need to carefully consider what type of packaging and even the labels your brand will have. Further, you can ask for some assistance about this with your polo shirt designer.

You also need to consider the following:

- Labeling: Make your label as unique and eye-catching as possible. You can use your name on it or a creative label that can capture the interest of people.

- Tags: In making your tags, make sure that they are as durable and unique as possible. Try adding your logo to it or the description of your polo shirt.

- Packaging: You must think of something convenient to carry for your packaging. Easy to carry yet durable and attractive.

Polo shirt manufacturers are meant to help entrepreneurs be able to make their brands relevant to the market. Having the best polo shirt manufacturer by your side is the most efficient way to build your brand centered on polo shirts.

In Conclusion

The polo shirt manufacturing industry is a vibrant and ever-evolving landscape, offering opportunities for aspiring entrepreneurs. By understanding the ins and outs of the industry, from design and production to quality control and branding, you can equip yourself with the knowledge needed to create a successful polo shirt brand.

Whether you’re drawn to the classic appeal of a cotton polo or the sporty functionality of a polyester blend, the possibilities for creating unique and stylish designs are endless. By collaborating with experienced manufacturers, you can tap into their expertise and resources to bring your vision to life.

So, what are you waiting for? Contact us, and let’s make your dreams possible!