Puffer jackets—those warm, puffy coats for cold days—provide more than just a stylish look. Wondering about the craftsmanship behind them? These jackets blend style and functionality, making them perfect for winter escapades.

Unique construction makes puffer jackets stand out from regular coats. Instead of flat layers, they have tiny compartments filled with down feathers or synthetic fluff. Imagine tiny pockets of warm air wrapped around you! This special design is what makes puffer jackets so snuggly. It’s like having a personal cloud to cuddle up in.

Let’s explore how these cozy garments come together. Breaking down the materials, construction, and essentials of a great puffer jacket will reveal their magic. Whether you’re a designer or a fashion enthusiast, diving into these winter essentials is a journey worth taking.

Understanding puffer jacket manufacturing

Imagine shivering in the cold. A puffer jacket is your cozy escape. Aside from boosting your style; it also protects against winter’s chill. Imagine wrapping yourself in a warm embrace, not just wearing a fashionable item.

Originally crucial for explorers in harsh winters, puffer jackets have since become a fashion staple. These early jackets were simple but effective. Over time, they transformed from survival gear into stylish pieces. Seeing puffer jackets is now a common sight in both busy city streets and snowy mountain peaks.

What makes a puffer jacket truly valuable is its versatility. Wear it alone on mild days or layer it for extreme cold. Adapting to various needs, they’re a must-have in any wardrobe.

Designing the perfect puffer jacket

Designing a puffer jacket involves several key steps. Every step in the process guarantees the final product reaches top quality. Setting clear goals begins the journey, leading to a completed design.

Steps on designing a puffer jacket

Designing involves several crucial steps to ensure the final product meets your objectives and connects with your target audience. Understanding these essential steps will guide you in creating the ideal puffer jacket.

1. Know why you’re creating this jacket

Before jumping into the exciting design phase, think about the purpose behind your puffer jacket. Are you starting a new clothing line, adding a cozy item to your collection, or crafting something unique for your brand?

Having a clear goal helps guide your design. Also, think about who you’re making this jacket for. Looking to appeal to sporty folks or trendy city dwellers?

Understanding your purpose will guide the process and make sure the final jacket aligns with your goals and satisfies your customers.

2. Gather ideas that inspire your vision

Inspiration is the foundation of great design. Begin by collecting ideas that align with your vision for the jacket.

What colors, shapes, or even logos pop into your head? Collecting pictures, sketching ideas, or crafting a mood board can spark inspiration. Platforms like Pinterest and Instagram offer endless possibilities to refine your style.

3. Decide how to design it

With your goals set and inspiration in place, the next step is to focus on designing your puffer jacket. Consider who will create the final design. You have three options:

-

Design it yourself

This option works best if you have design tools and skills. It’s cost-effective but time-consuming since you handle all aspects of the design.

-

Template magic

Many free or paid customizable templates are available online. These templates offer a starting point and can be personalized to fit your brand.

-

Ask a designer to help you

Looking for someone else to bring your design to life? Seek out a talented designer who can make your vision a reality. Speeding up the process is possible, but clear communication is key to success.

Creating something special that resonates with people involves having fun and letting creativity flow. Embrace the process and let your imagination take charge!

Types of puffer jackets

With a design concept in hand, selecting the right style for your puffer jacket is next. Many styles offer distinct vibes. Let’s check out some popular options.

1. Long Puffer Jacket

Source: Brandsloft

Long puffer jackets reach below the hips, offering ultimate warmth and a touch of sophistication. Designed for the coldest days, their length complements neutral tones well.

2. Short Puffer Jacket

Source: wconcept

Seeking a blend of casual comfort and versatility? Short puffer jackets, ending at the waist or just below, offer warmth and ease of movement. They are perfect for daily wear and can be styled for any occasion.

3. Hooded Puffer Jacket

Source: Lululemon

A classic choice, hooded puffer jackets combine style and practicality. With various design options, from matching to contrasting colors or even faux fur trims, the hood adds a touch of personality while providing protection from the elements.

4. Belted Puffer Jacket

Source: Moncler

Adding a belt to a puffer jacket gives it a tailored flair. This design accentuates the waist, creating a sleek and feminine silhouette. Match with leggings, jeans, or knee-high boots for a chic, polished outfit.

5. Oversized Puffer Jacket

Source: Martin Valen

Oversized puffer jackets offer a bold and trendy look with their relaxed, roomy fit. Perfect for those who enjoy making a striking fashion statement, their exaggerated proportions stand out.

6. Cropped Puffer Jacket

Source: Be Activewear

Cropped puffer jackets offer a modern twist with their waist-length cut. This style not only gives an edgy look but also highlights your outfit perfectly. Embrace contemporary fashion with this shorter design.

7. Reversible Puffer Jacket

Source: Pinterest

Two styles in one? That’s the beauty of a reversible puffer jacket! With different colors or patterns on each side, you can effortlessly change your look without needing multiple jackets.

8. Lightweight Puffer Jacket

Source: Heat Holders

Milder weather calls for lightweight puffer jackets. Thinner than their bulkier counterparts, they work well alone on warmer days or layered for extra warmth when temperatures drop. Enjoy their flexibility for varying weather conditions.

Different styles offer their own distinct charm, whether focused on warmth, fashion, or flexibility. Knowing the options lets you create a puffer jacket that excels in both function and style.

Anatomy of garment

To craft the perfect puffer jacket, understanding its structure is essential. Each part plays a role in the jacket’s look, feel, and warmth. While designs vary, most share these basic elements. Let’s break down the key components of a puffer jacket.

What are the parts of puffer jackets?

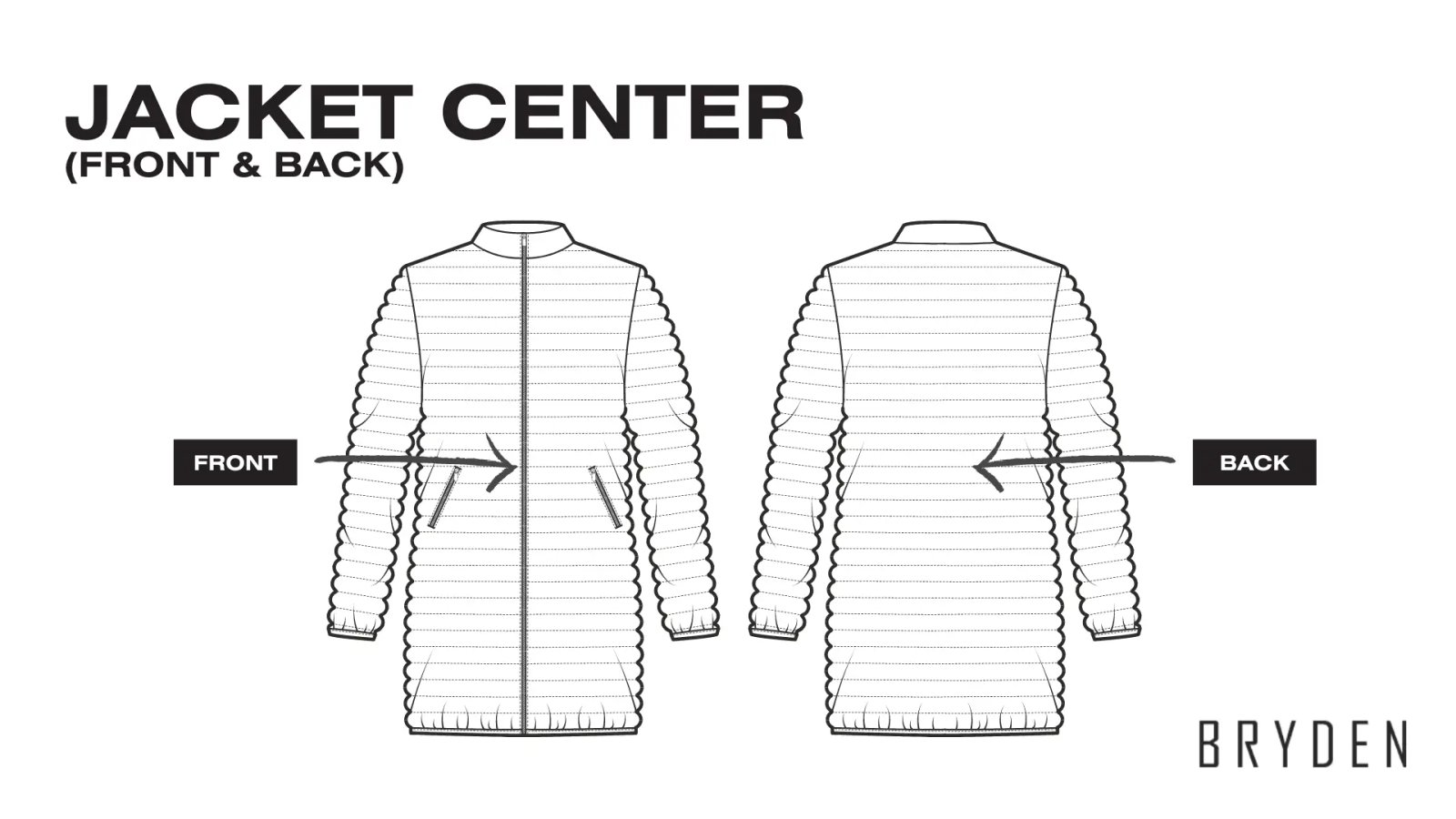

1. Jacket center front and back

Picture the jacket’s front and back as its spine. The center front line runs straight down from the collar to the bottom. The center back is the middle part of the jacket’s back. These parts are super important because they shape the whole jacket.

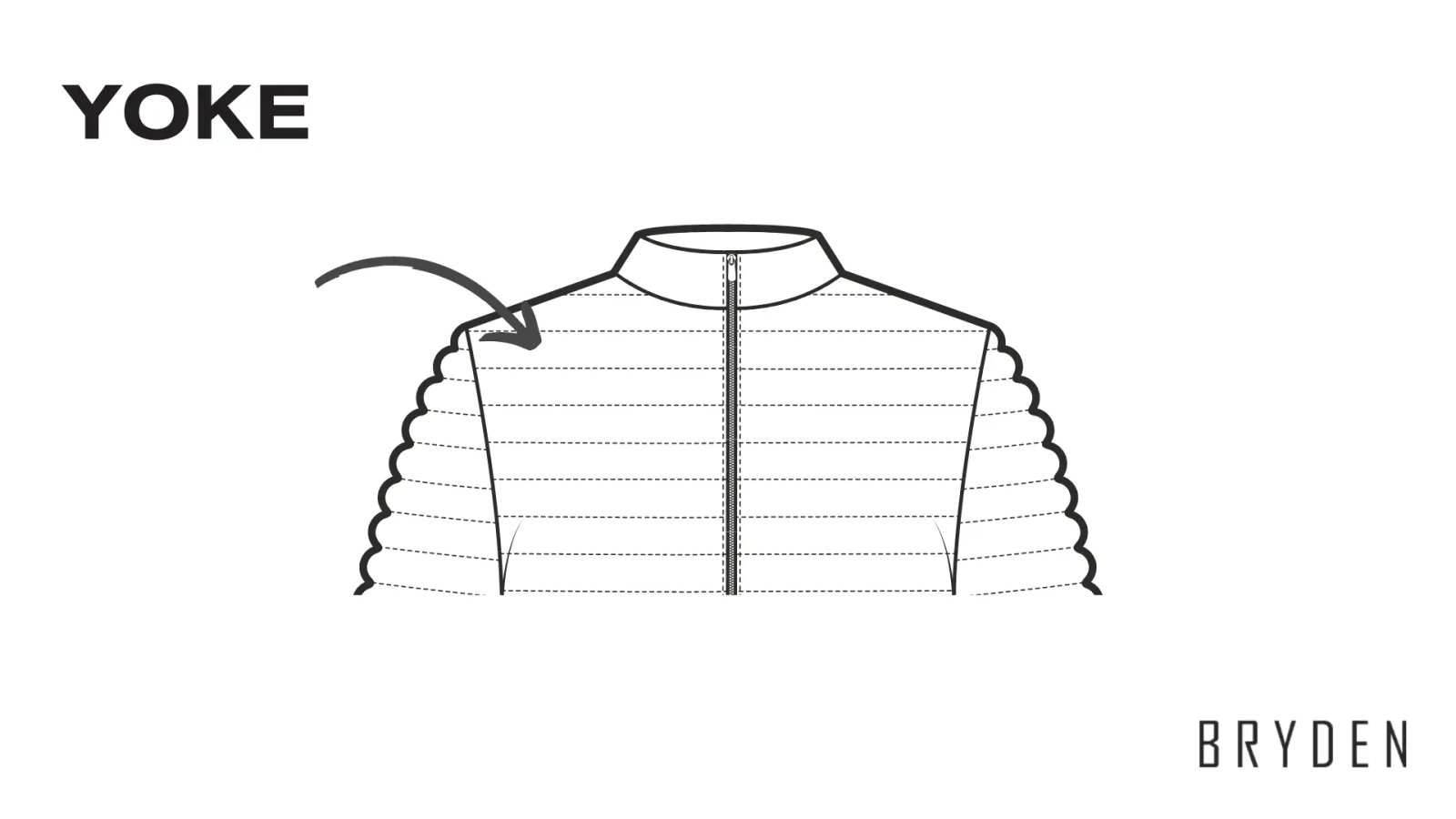

2. Yoke

Not all jackets have a yoke, but it’s like the jacket’s shoulder support when it does. It’s usually on the shoulders or waist. The yoke makes the jacket look good and feel comfortable. It also helps the jacket keep its shape.

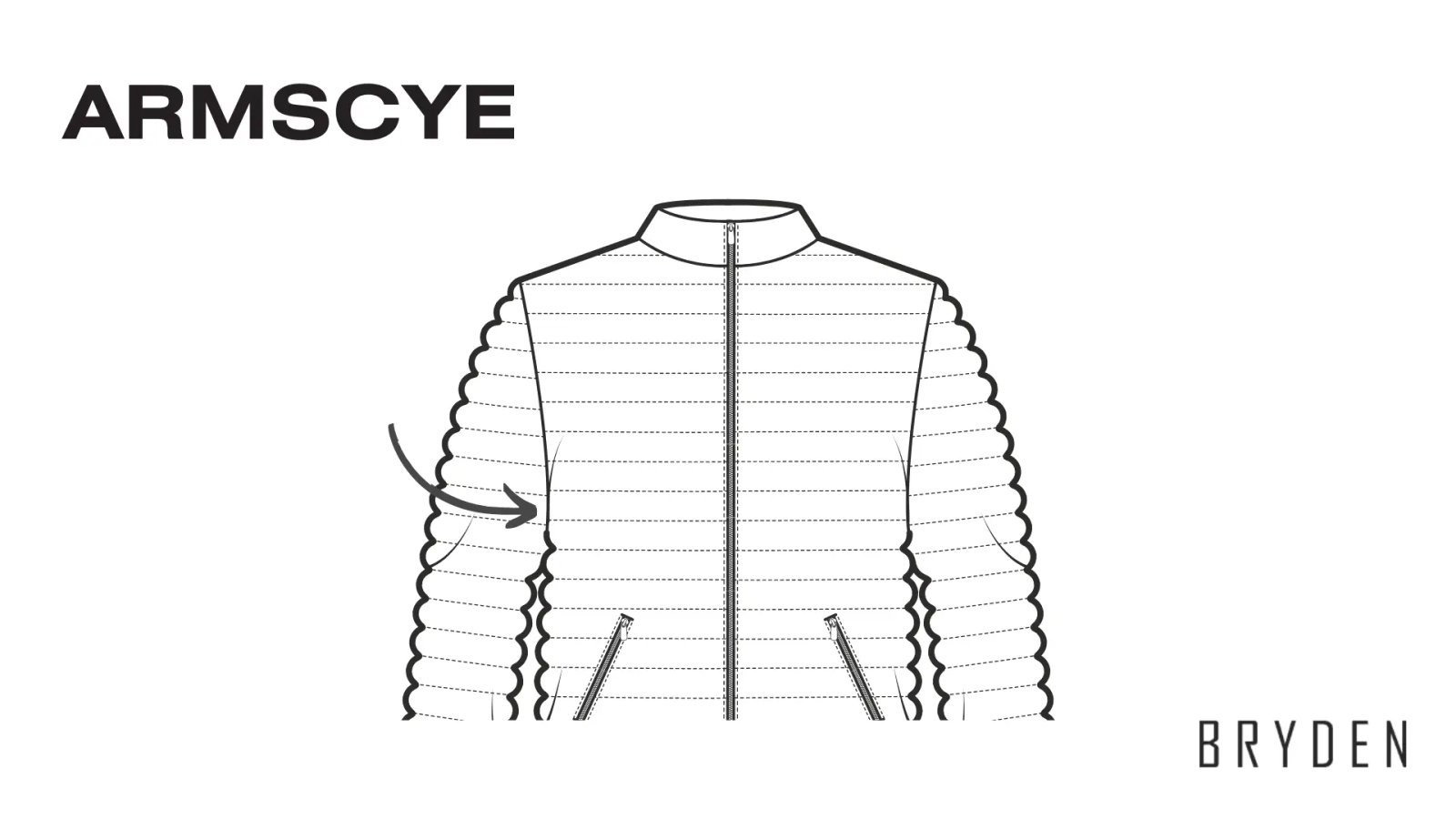

3. Armscye

Imagine the armscye as the jacket’s doorway for your arms. This curved opening connects the sleeve to the body, making sure you can move freely.

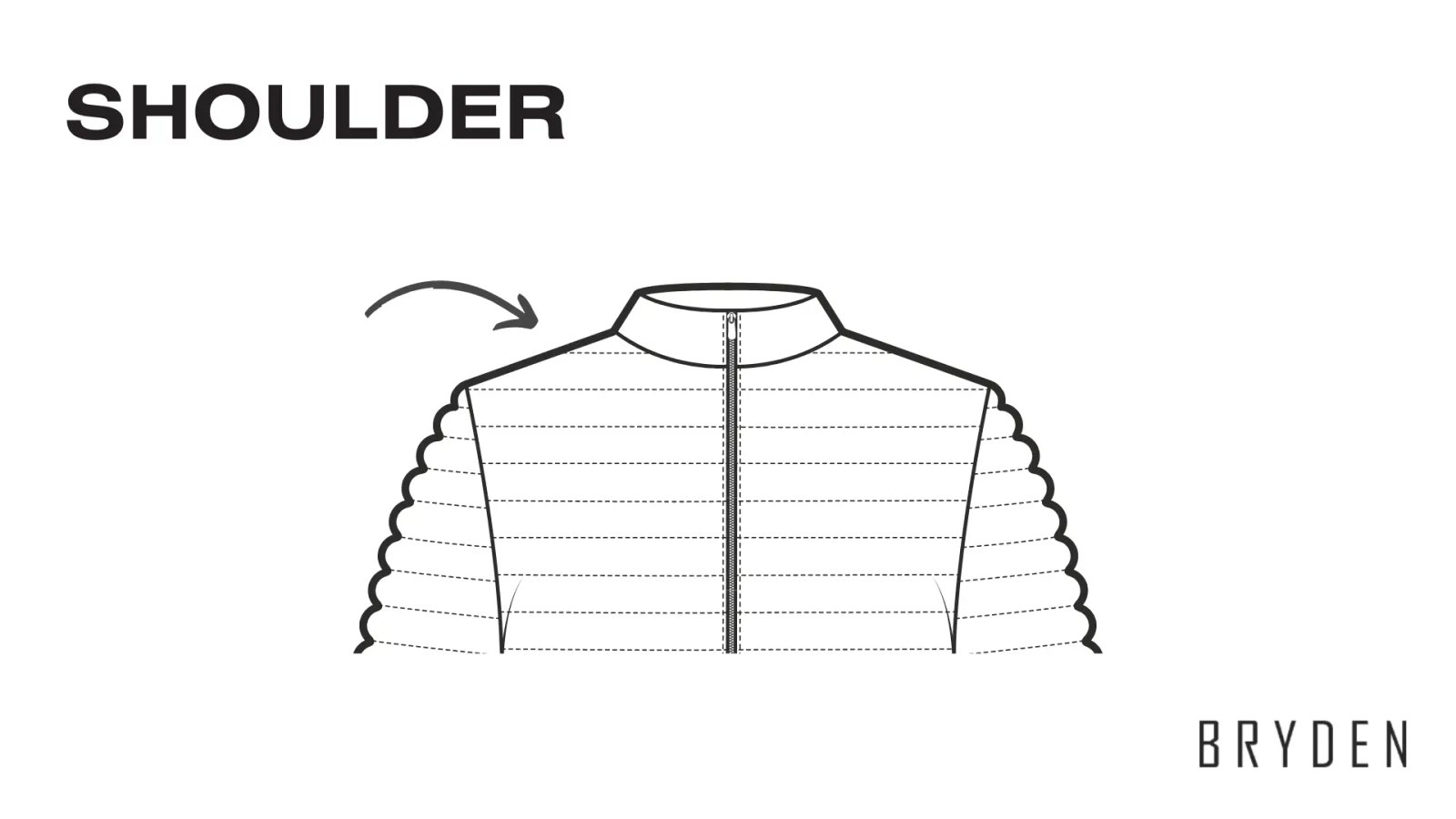

4. Shoulder

The shoulder seam connects the sleeve and the neck. This part is very important for a jacket to fit well. The shoulder seam works with other parts to make sure the jacket fits the upper body correctly.

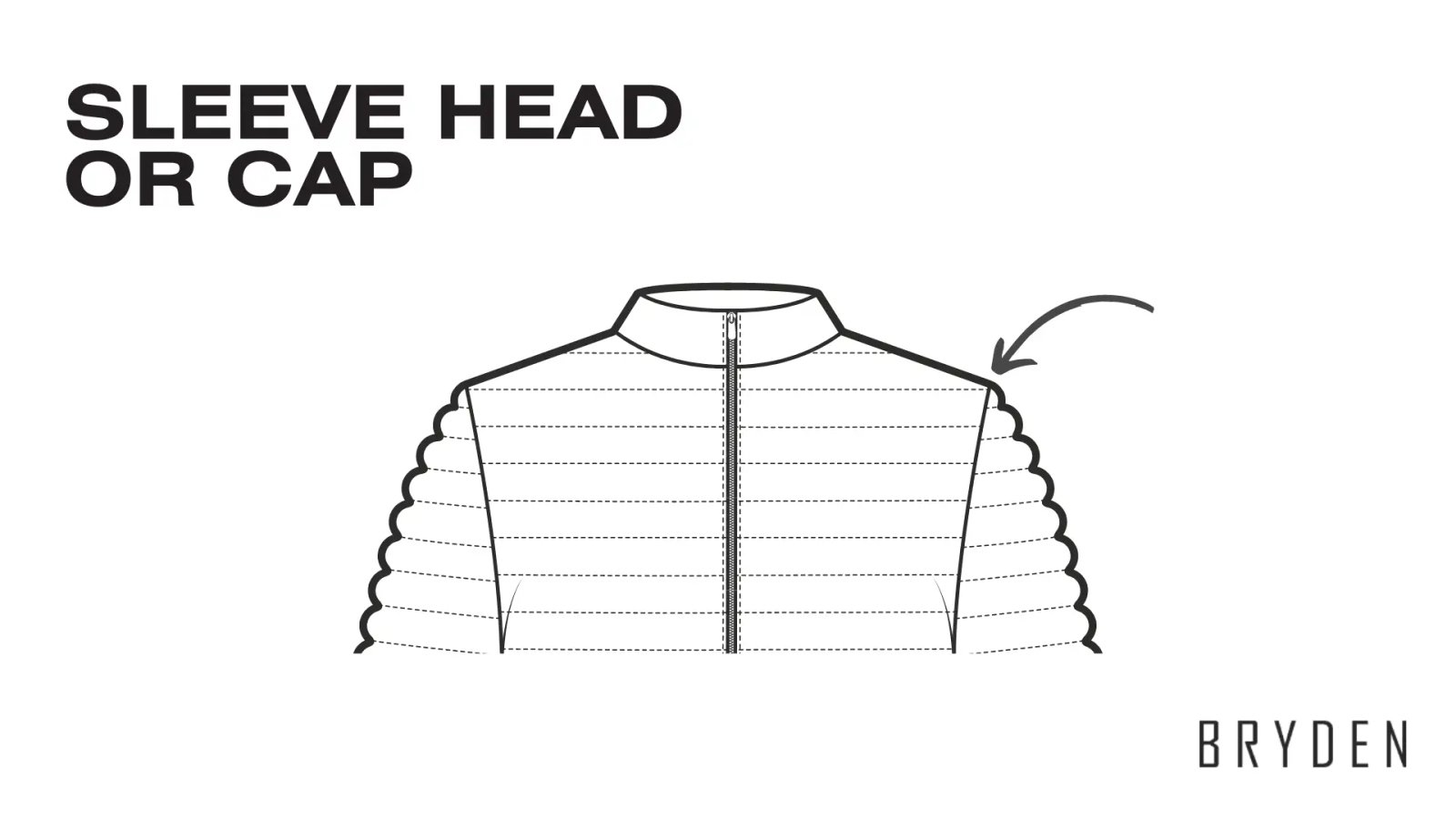

5. Sleeve head or cap

The sleeve head, or cap, is the top section of the sleeve. People sew it into the armscye. Extra fabric in the sleeve head allows for movement. This extra fabric makes the shoulder area comfortable.

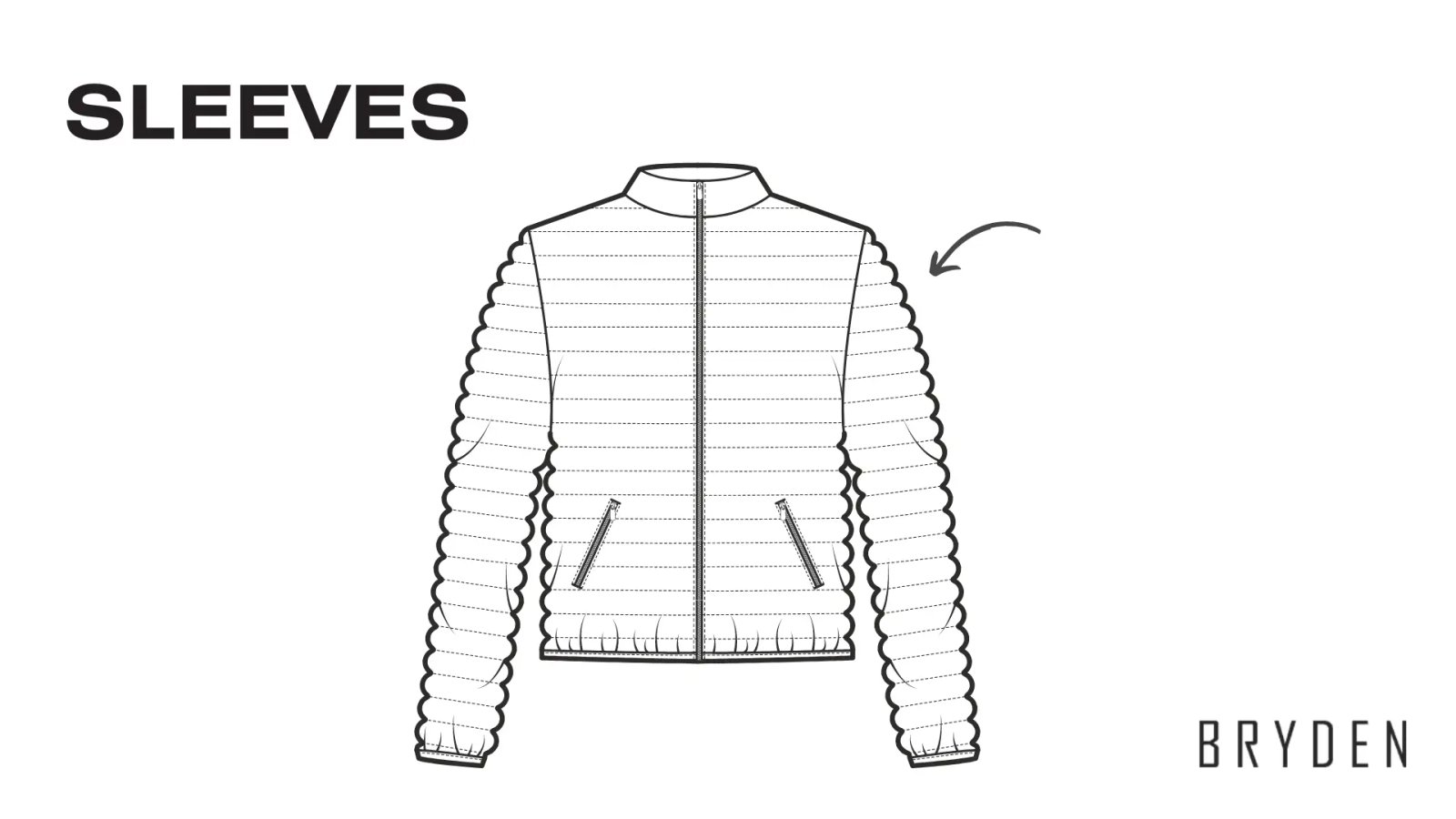

6. Sleeves

Puffer jacket sleeves keep you warm and comfy. They protect your arms from the cold.

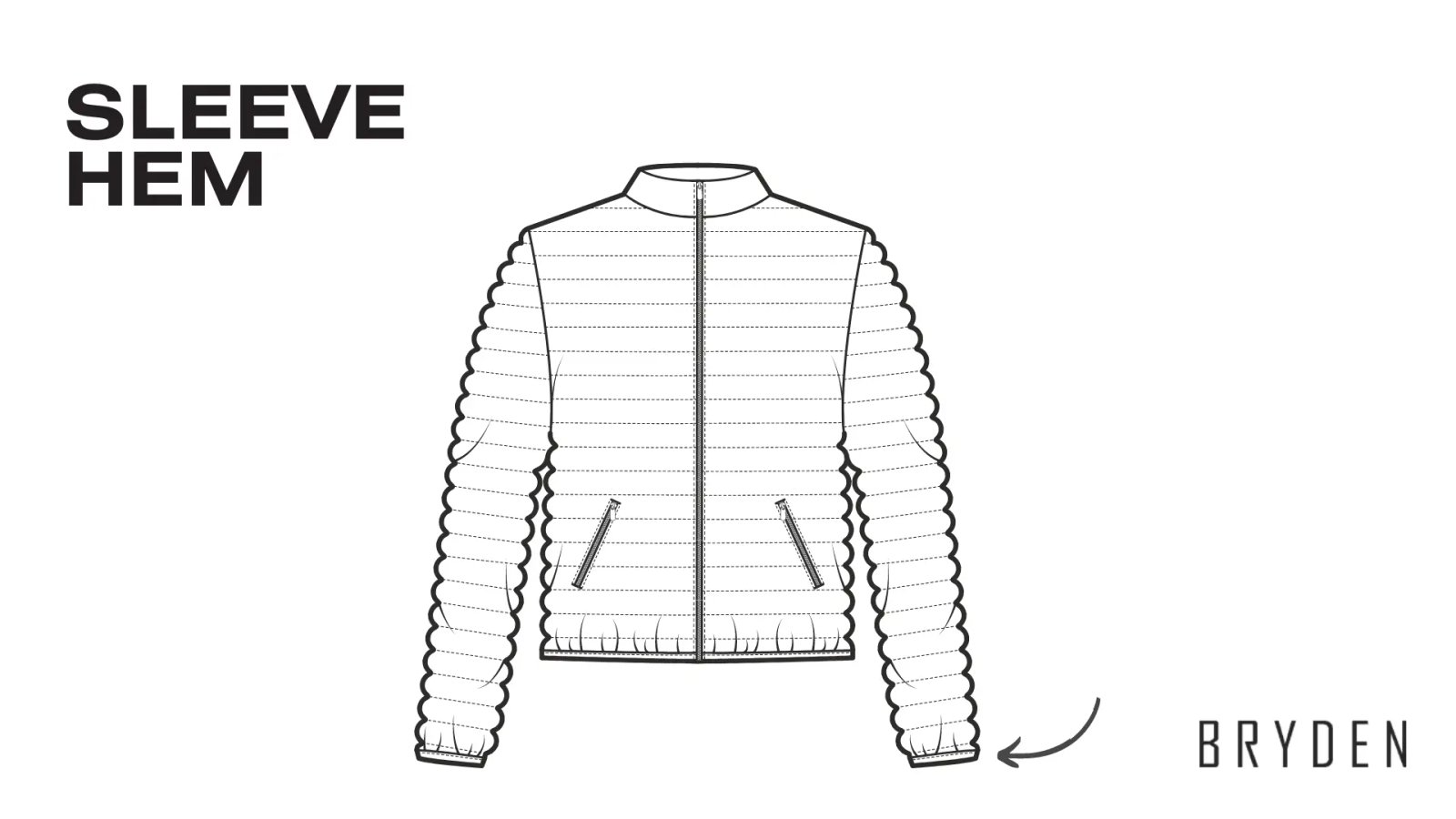

7. Sleeve hem

The sleeve hem is the bottom part of the sleeve. It is near your wrist. Some puffer jackets have elastic or ties at the sleeve hem. These keep cold air out and make the jacket fit snugly.

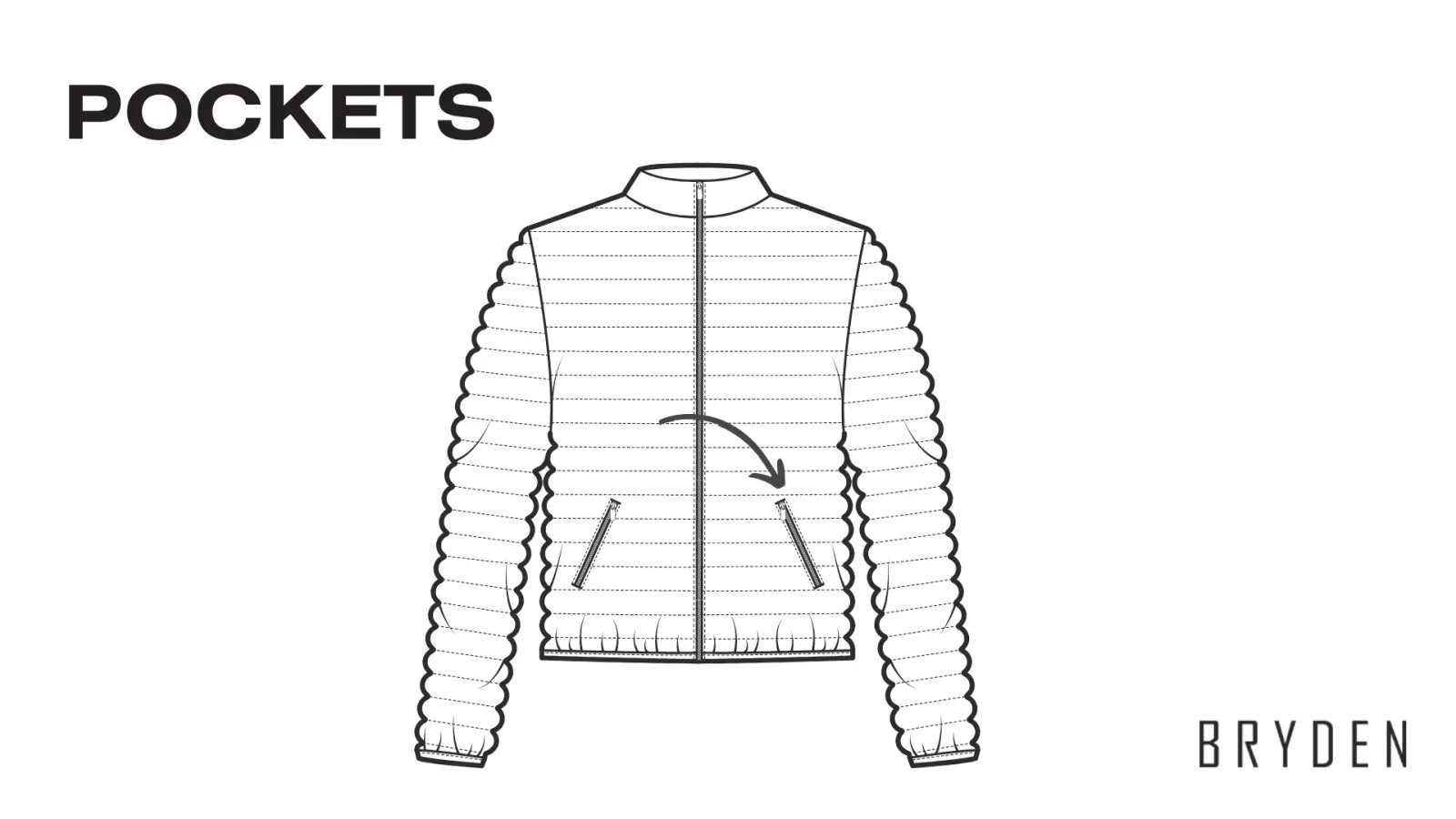

8. Pockets

Puffer jackets have pockets. Pockets keep your hands warm. They also keep your things safe. Some pockets have zippers or snaps. These things make the jacket useful.

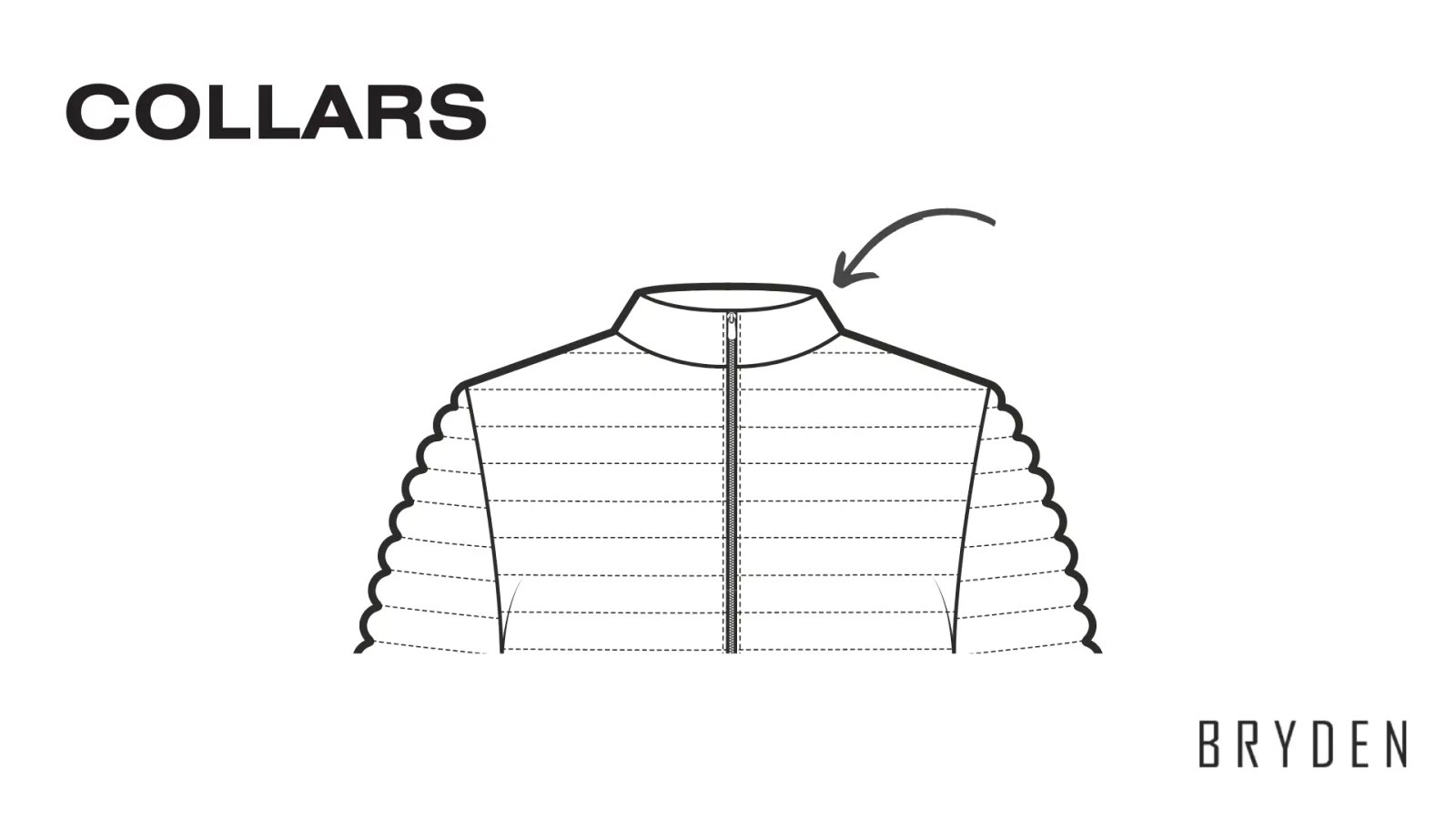

9. Collars

Collars come in different styles. You can find stand collars or hoods on many jackets. Collars keep you warm and look nice.

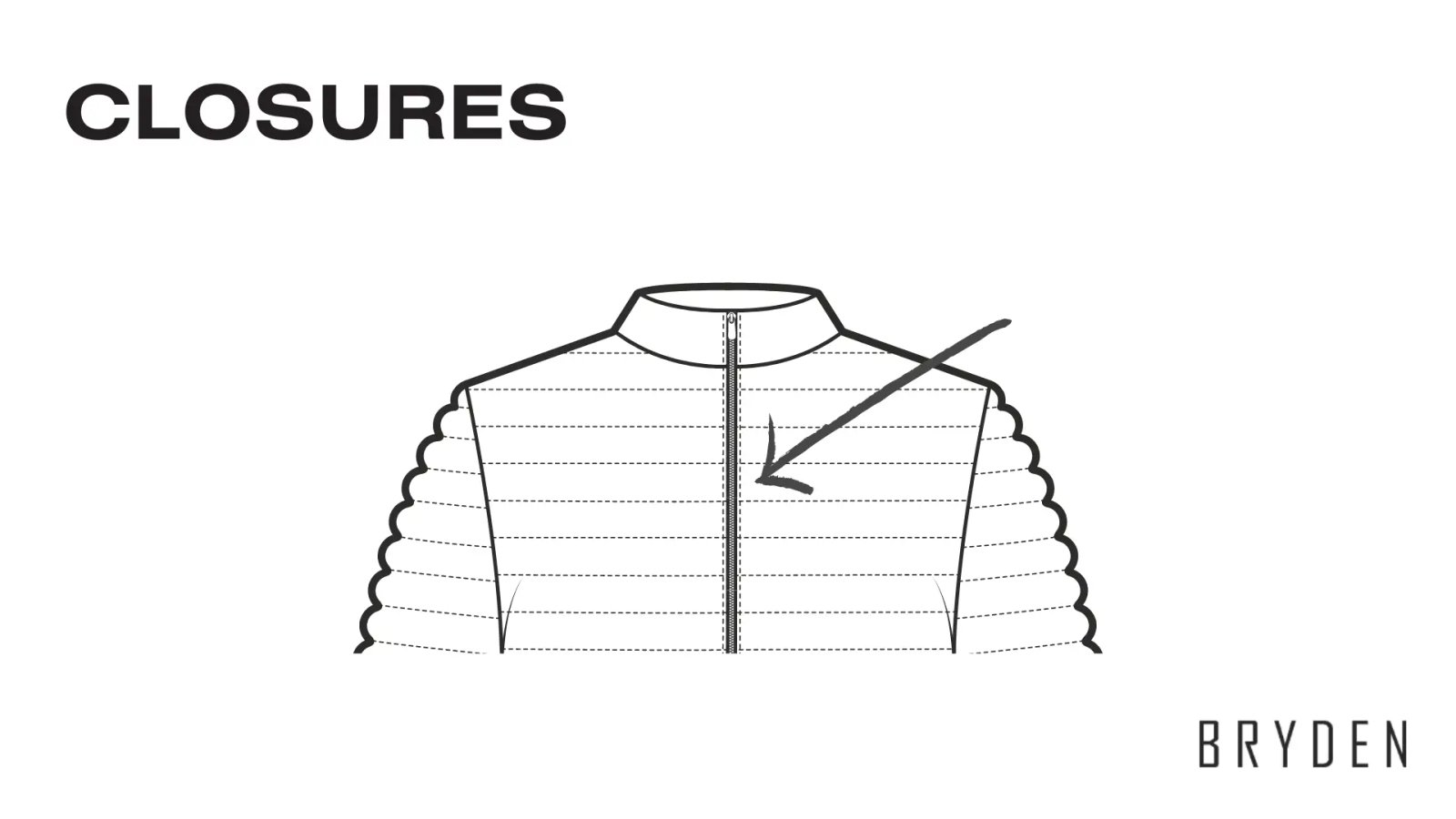

10. Closures

Closures keep your jacket closed and keep cold air out. A zipper is popular. It is easy to use and keeps things closed. Jackets and pockets use zippers.

These are the main parts of a puffer jacket. Some jackets have extra things, like drawstrings or belts. These extras depend on the jacket’s style. Knowing these parts helps make a jacket that works well and looks good.

Choosing quality fabrics

Fabric forms the foundation of any puffer jacket. It defines the jacket’s appearance, comfort, and how well it shields against the cold. Serving as the first line of defense, the outer layer of a puffer jacket is crucial for weather protection.

The best fabric depends on what you’ll use the jacket for. Adventurers might need a tougher fabric than someone who just wants to stay cozy on cold days.

1. Nylon

A popular choice for many reasons. Strong yet lightweight, nylon excels in outdoor adventures. Available in various colors, it maintains its hue over time. Plus, it’s tough without being heavy. On the downside, nylon can feel stiff and doesn’t breathe as freely as some other fabrics.

2. Polyester

With sturdy fibers, polyester resists tears, stretching, and fuzz. Water rolls right off polyester, keeping stains at bay. Mixing it with cotton enhances durability and reduces wrinkling. Offering better airflow than nylon, polyester provides comfort for long wear, though it might not withstand extreme conditions as well.

3. Fleece

Fleece introduces a different texture to puffer jackets—cozy and lightweight, it’s ideal for casual wear. Its softness provides warmth without adding bulk. Despite its comfort, fleece lacks the toughness and water resistance of other materials, making it more suitable for everyday wear than severe weather.

4. Suede

Adding a touch of luxury, suede enhances puffer jackets with its strength and softness. The unique texture brings visual interest and sophistication to your outerwear. Unfortunately, it’s more likely to stain and might not be the best choice for unpredictable weather. Suede puffer jackets are all about style rather than heavy-duty use.

5. Recycled materials

Recycled nylon and polyester are now popular for eco-friendly puffer jackets. These materials provide the same durability and water resistance as traditional fabrics while supporting environmental sustainability. Although recycled options might cost more, they attract eco-conscious buyers.

Selecting the perfect fabric is crucial for designing a puffer jacket that appeals to your audience, whether they value adventure or style. The right fabric enhances functionality and overall appeal, making the jacket stand out.

Choosing the perfect insulation

Source: Alpkit

What makes a puffer jacket truly cozy? The answer lies in its insulation. This fluffy fills, tucked into little pockets is the secret to warmth. There are three main types: down, synthetic, and a mix of both.

1. Down puffer jacket

Incredibly light and compact, down keeps you warm like the fluff beneath a duck’s feathers. Imagine the comfort of that soft warmth wrapped around you. While it’s amazing, not all down comes from ducks or geese. Down shines in cold, dry weather, and it’s known for its exceptional warmth-to-weight ratio.

2. Synthetic puffer jacket

Synthetic insulation is the human-made alternative. It might not be as fancy as down, but it holds its own, especially in wet conditions. Easier to maintain, this style suits various climates and conditions. A great choice for many different weather scenarios.

3. Hybrid puffer jacket

Blending the warmth of down with synthetic fill’s water resistance creates a versatile jacket. This combination means you can tackle various weather conditions without constantly layering up. Plus, they often have stretchy parts for easy movement.

Adding water-resistant coatings to the outer shell boosts a puffer jacket’s functionality. While these coatings handle light rain, sealed seams and waterproof zippers become crucial for severe weather.

Warmth in a puffer jacket largely depends on its insulation level. The type and amount of insulation used determine how well the jacket performs in various climates.

Pattern making and cutting

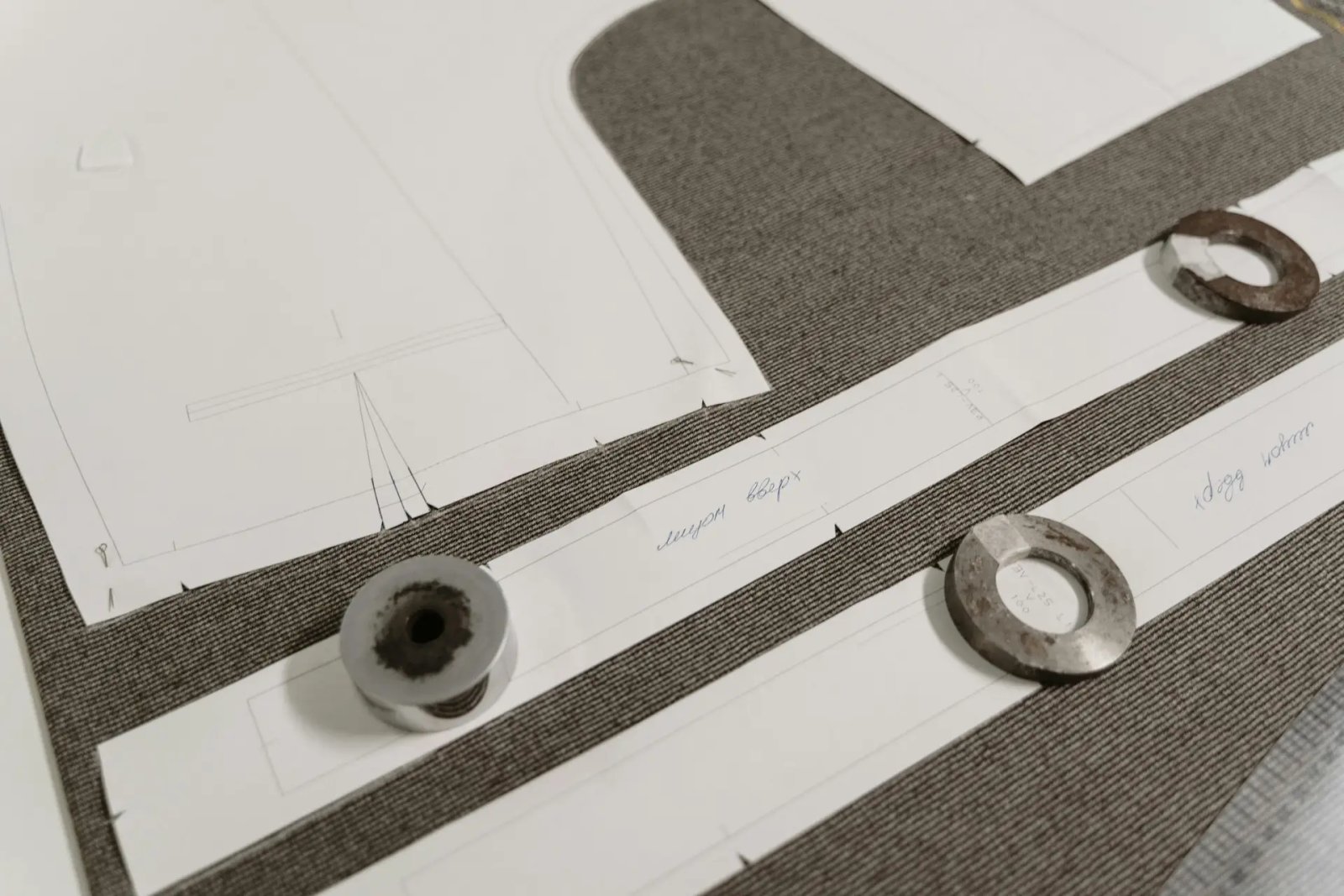

Building a puffer jacket starts with a plan and some serious cutting. It’s like creating a puzzle where every piece counts. First, we design the jacket’s shape. This blueprint, called a pattern, guides us in cutting the fabric.

Picking the right pattern is crucial. It needs all the right pieces – front, back, sleeves, and collar. Sometimes, we need to tweak the pattern a bit to make it perfect. This means adjusting sizes or lengths to fit the design.

Once the pattern is perfect, it’s time to cut the fabric. Each piece of the pattern is a puzzle piece. They carefully slice through the fabric to create these pieces. Skilled hands or precise machines can do this job. It’s important to cut accurately, so everything fits together smoothly later on.

Pattern making and cutting are the first steps in bringing a puffer jacket to life. These early stages establish the foundation for the entire manufacturing process.

Pattern making (how to with samples)

Creating the perfect puffer jacket starts with a detailed blueprint: the pattern. Each style demands a unique approach. Let’s break down two popular designs.

1. Reversible cropped puffer jacket

Source: Papercut Patterns Ltd.

A reversible cropped puffer jacket needs a special pattern. Imagine a mirror image; that’s how we design it. The jacket is shorter, ending above the waist for a modern look. Both the front and back look identical to allow for flipping. Even the sleeves and collar are reversible. They add special marks to guide our team when cutting and stitching.

2. Long belted hooded puffer jacket

Source: Vikisews

This requires a more complex pattern. It’s longer, with a belt to cinch the waist. The hood is made from several pieces for the best fit. We carefully measure and mark the pattern to ensure the belt matches the jacket perfectly.

Precision is key. Puffer jacket manufacturers carefully consider each jacket’s style and function to create a pattern that will result in a fantastic final product.

Marking tips for cutting patterns on fabric

Accurate fabric marking is crucial for achieving a high-quality puffer jacket. This step ensures that all components align correctly during the sewing process.

1. Marking with the right tools

Using the appropriate marking tools is essential. Fabric markers, tailor’s chalk, or water-soluble pens are commonly used to indicate key points such as notches and darts. These markings serve as guides for precise assembly.

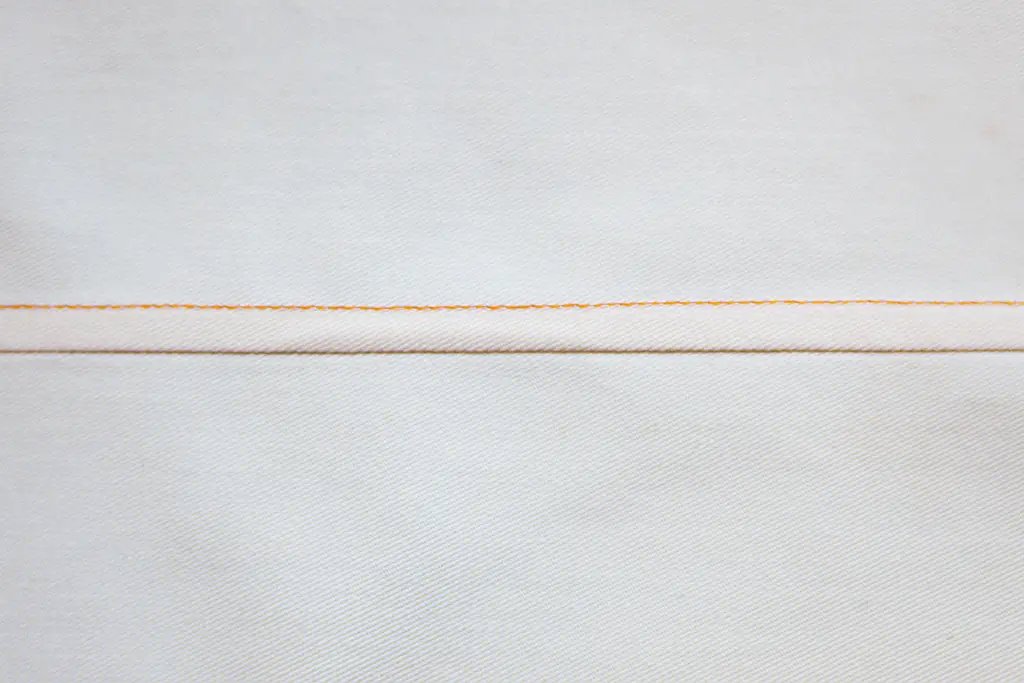

2. Quilting lines

For creating quilted sections, using a quilting ruler is essential. Straight lines marked on the fabric guide the quilting process.

3. Consistent spacing

Consistency is key for quilting lines. Decide how far apart you want each line and stick to it. This gives your jacket a polished look and ensures it’s warm everywhere.

4. Proper pinning of layers

To prevent fabric shifting during the marking and sewing process, the use of wonder clips or pins is recommended. These tools help secure the fabric, insulation, and lining in place, ensuring accurate placement of markings.

By following these guidelines, manufacturers can achieve precise fabric marking, leading to a well-constructed and visually appealing puffer jacket.

Cutting and sewing in puffer jacket manufacturing

Transforming fabric into a puffer jacket requires precision and skill. The process begins by carefully cutting out the pattern pieces from the chosen fabric. These pieces serve as the foundation for the jacket.

Sewing the outer shell and inner lining together requires meticulous attention. Every detail matters here to ensure a perfect fit and finish.

Adding functionality and style comes next with the careful attachment of zippers, buttons, or snaps. Cuffs, collar, hood, and sleeves are then sewn in, defining the jacket’s unique shape.

To achieve the signature puffiness, insulation is carefully inserted into the jacket. Filling the jacket with down feathers or synthetic material ensures warmth and comfort. This step is crucial for making the jacket cozy and functional.

Final touches involve precise stitching of remaining seams and adding any last embellishments. The result is a puffer jacket that’s both high-quality and ready to keep you warm.

How to cut the puffer jacket

Precision cutting is the foundation of a well-made puffer jacket. This process involves transforming the fabric into the individual components outlined by the pattern.

Two main methods exist for cutting fabric: manual and computerized. With manual cutting, pattern pieces are carefully placed and cut out by hand, requiring skill and precision.

In contrast, computerized cutting utilizes advanced technology. A machine processes the pattern data to cut the fabric with precision. Opting for this method not only speeds up production but also ensures consistency, especially in large quantities.

Precision in cutting fabric is crucial for a smooth assembly process. No matter which technique you use, accurate fabric pieces make a big difference.

Different types of seams for puffer jackets

In a puffer jacket, seams are more than just stitches; they determine its strength and look. Selecting the right seam type hinges on the design, fabric, and intended use.

-

Plain seam

Source: Ageberry

This is the most basic seam, formed by stitching two fabric edges together. While simple, it’s often used in areas that experience minimal stress.

-

French seam

Source: In The Folds

French seams create a polished finish by encasing raw edges within the seam. Ideal for lightweight fabrics, they are perfect when a clean appearance is essential.

-

Flat felled seam

Source: Seamwork

For durability in high-stress areas like side seams, flat felled seams are your go-to. By folding and stitching down the seam allowance, they provide added strength and longevity.

-

Bias bound seam

Source: Closet Core Patterns

A bias bound seam involves encasing raw edges in a fabric binding. This method provides a neat finish and extra durability, making it suitable for areas prone to wear and tear.

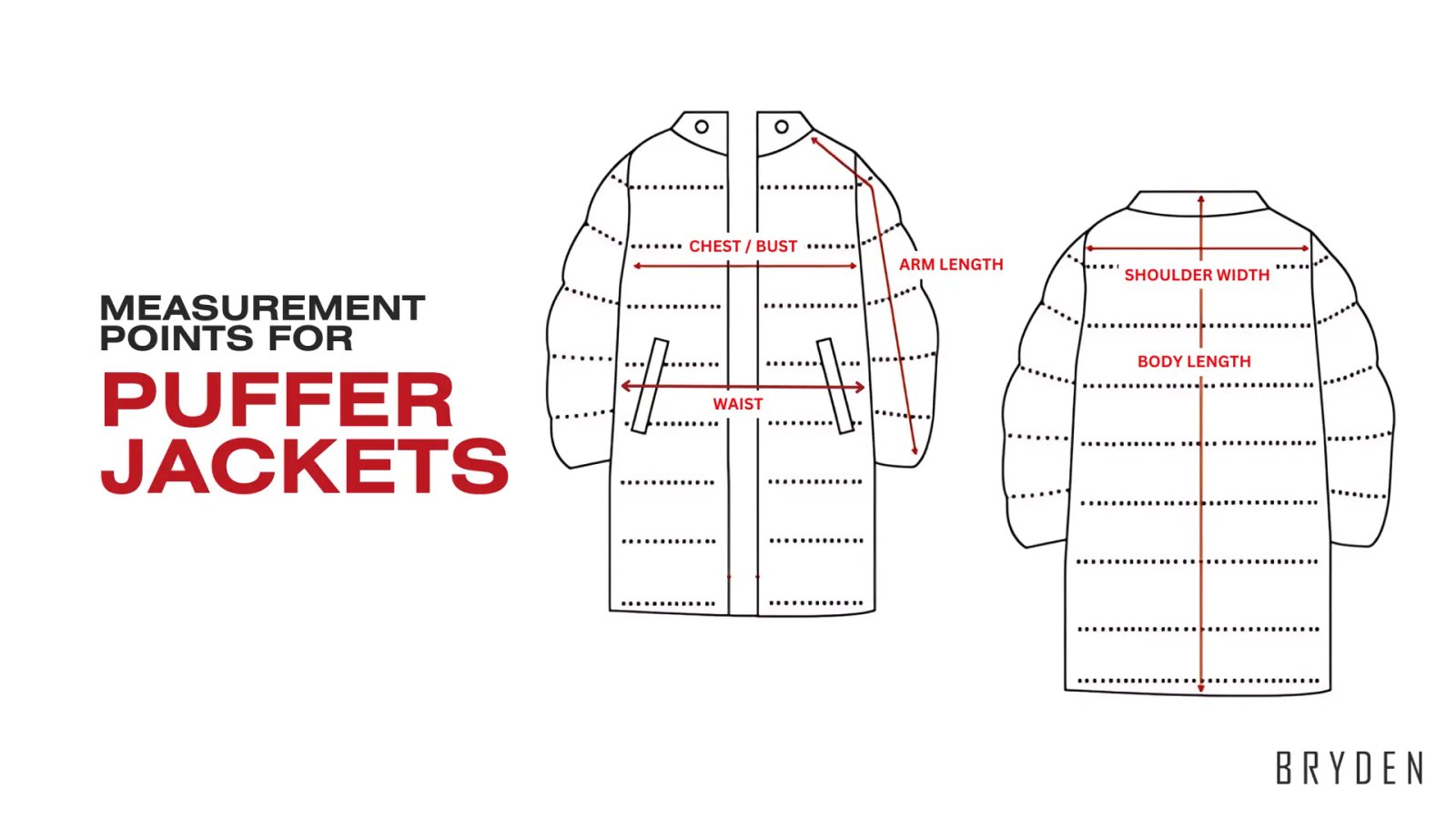

Measurement points for puffer jacket

Getting precise measurements is crucial for crafting a puffer jacket that fits perfectly. These key points guide the design process to ensure optimal comfort and style.

1. Chest/Bust

Chest circumference is taken at the fullest part to ensure a comfortable fit around the torso.

2. Shoulder Width

Measured from one shoulder tip to the other, shoulder width influences the jacket’s overall balance and drape.

3. Arm Length

To determine sleeve length, measure from the shoulder point to the wrist. This ensures the sleeves provide adequate coverage and comfort.

4. Waist Measurement

Measured at the narrowest part of the waist, this dimension is crucial for jackets with a defined shape or cinched fit.

5. Body Length

Defining the jacket’s overall style and coverage requires measuring from the base of the neck to the desired length.

Using these measurements forms the basis for a puffer jacket that combines both style and comfort.

The art of printing

Printing transforms a puffer jacket from a basic garment into a fashion statement. Understanding different printing methods helps in choosing the right technique for your design. Let’s look at the common methods used in puffer jacket manufacturing and their effects.

Common printing techniques used for puffer jackets

1. Sublimation printing

Source: FARTECH

Sublimation printing, or all-over print, covers the whole jacket with a design. Heat and pressure embed the pattern into the fabric, making it a durable option. Prints created this way remain vivid and permanent, resisting fading and cracking over time.

2. DTG printing

Source: JW Anderson

For detailed images and photographs, Direct-to-garment (DTG) printing offers an ideal solution. By spraying ink directly onto the fabric, this method ensures precision and vividness in every design. The result is a soft finish that works well for complex images.

3. Screen printing

Source: Ade Dehye

Ink flows through a mesh screen in screen printing, thanks to a stencil and squeegee. This technique provides vibrant colors and works wonders, particularly on dark fabrics.

Different techniques offer unique benefits based on design needs and fabric type. For more information or specific questions about these methods, contacting a puffer jacket manufacturer can be helpful.

Different types of garment washing for puffer jackets

Garment washing transforms the look, feel, and durability of puffer jackets. Each method gives a unique finish and texture to the fabric. Choosing the right wash can enhance your jacket’s appearance and performance. Here’s a look at different types of garment washing for puffer jackets.

1. Garment Wash

Source: thisisneverthat

A garment wash refreshes the fabric, giving it a smoother, more polished appearance. This process cleans away impurities and enhances texture. Using mild detergent and cold water preserves both the structure and insulation of the jacket.

2. Acid Wash

Source: Nuuly

Want a jacket with a faded, retro vibe? Acid wash might be the perfect choice. This method involves chemicals that create a distressed, worn look. The result can range from subtle fading to a bold bleached white effect, depending on the chemical mix.

3. Enzyme Wash

Source: CLOTHBASE

Imagine a fabric that feels softer and looks more refined. Enzyme wash achieves this by using biological enzymes to reduce pilling and enhance comfort. The result is a jacket with a smoother texture while retaining its durability.

4. Pigment Wash

Source: ILLICIT BLOC

A pigment wash adds a faded, vintage charm to the fabric. This technique uses pigment dyes applied to the surface, creating a unique, worn-in texture. The end look is relaxed and stylish, perfect for a casual, standout appearance.

5. Sand Wash

Source: Garmentory

For a touch of luxury, sand washing does the trick. Abrasives like sand smooth the fabric, giving it a soft, suede-like feel. This process not only creates a distinct distressed look but also adds a refined, plush texture to the jacket.

Each washing method brings something different to the table, impacting the final look and feel of the puffer jacket. Exploring these options helps in crafting a jacket that perfectly aligns with your design vision.

Fabric dyeing technique for puffer jackets (add images)

Dyeing brings a new dimension to puffer jackets, turning them from simple to spectacular. Each method offers a unique touch, turning a standard jacket into a standout piece. Here’s a glimpse into some creative fabric dyeing techniques used in puffer jacket manufacturing:

1. Dip Dyeing

Source: Target

Colors merge seamlessly from dark to light with dip dyeing. The technique involves partially dipping the fabric into a dye bath, creating a smooth gradient effect. This method gives jackets a stylish, dynamic look as colors transition effortlessly.

2. Tie-Dyeing

Source: PROJECTISR

Swirls, pops of colors, and playful patterns define tie-dyeing. By twisting, folding, or tying the fabric before dyeing, you get intricate designs that burst with personality. This method turns puffer jackets into vibrant canvases of unique, eye-catching style.

3. Shibori

Source: ModeSens

Shibori’s resist dyeing technique creates exquisite patterns on fabric. Before dyeing, fabrics undergo folding, stitching, or clamping to prevent the dye from reaching certain areas. This traditional Japanese craft infuses any puffer jacket with an artisanal and refined charm.

4. Marbling

Source: Spliff Tees

Swirling, marbled patterns come to life through marbling. Dyes float on water’s surface and transfer their intricate designs to the fabric. Each puffer jacket becomes a unique work of art with mesmerizing, swirling patterns that capture attention.

5. Overdye

Source: Amatera

Layering multiple colors with overdyeing gives jackets a rich, textured appearance. This technique enhances the fabric with complex, multidimensional hues. The result is a puffer jacket with depth and character, making a bold, stylish statement.

Exploring these dyeing techniques offers endless possibilities for creating striking and personalized puffer jackets. Understanding these methods helps in selecting the best approach to make your design stand out.

Quality control measures

Ensuring quality is a top priority in puffer jacket manufacturing to meet high standards for durability, functionality, and appearance. Through careful checks during production, each jacket can be reliable and stylish. Here’s a glimpse into the quality control process:

1. Material Inspection

First, examine all materials meticulously. The outer shell fabric, insulation, and lining should be free from defects like tears or stains. Fasteners, including zippers and buttons, need to be tested for proper function and secure attachment. Any issues with these elements can impact the jacket’s usability.

2. Sizing and Fitting

Accuracy in size and fit is crucial. Verify that each jacket aligns with the intended size chart. Consistent measurements ensure a proper fit, contributing to overall comfort and satisfaction.

3. Stitching Quality

Focus on the stitching to confirm its strength and consistency. Look out for loose threads or uneven seams and ensure that all seams are finished correctly to prevent fraying. Properly spaced and secure quilting lines are essential to keep insulation evenly distributed.

4. Performance Testing

Perform a final inspection to assess whether the jacket meets performance standards. Tests should check for warmth retention, water resistance, and durability to ensure the jacket holds up under various conditions.

For maintaining a stellar reputation and satisfying customers, strict quality control is essential. Manufacturers who focus on these elements consistently produce puffer jackets known for their durability and top-notch performance.

Packaging and branding

In the world of puffer jackets, packaging and branding are essential. Good packaging safeguards the jacket during transit and makes the unboxing experience memorable. Branding builds a distinct identity that resonates with customers.

Packaging

Packaging has two key roles: safeguarding the jacket and making a strong first impression. Branded boxes or poly bags with logos add a professional touch. Eco-friendly materials show a commitment to sustainability. Extras like branded tissue paper, custom tags, and care instructions enhance the jacket’s appeal, while flyers or stickers boost brand visibility.

Source: Moncler

Consider Moncler’s approach. Their minimalist box with a garment bag, adorned with the logo, embodies elegance and sustainability. Such thoughtful packaging not only ensures the jacket’s safety but also elevates the customer’s unboxing experience.

Branding

Branding crafts a unique identity that resonates with customers. Creating a distinctive logo, choosing a color scheme, and developing a consistent brand voice are key steps. Customization options, such as embroidery or screen printing, reinforce brand recognition.

Source: Lyst

The North Face shines as an example of powerful branding. With a prominent logo and a blend of premium and recycled materials, these puffer jackets draw the eye of fashion enthusiasts. Eco-conscious shoppers also find them appealing. Effective branding helps differentiate the product in a competitive market.

Memorable products emerge when packaging and branding work seamlessly together. When executed thoughtfully, they enhance customer satisfaction and strengthen brand reputation.

Conclusion

Puffer jackets blend style and warmth, with their production involving careful fabric selection, precise cutting, sewing, and finishing. Each step, including quality control and packaging, ensures a high-quality final product.

To find the right partner, focus on those who offer excellent comprehensive puffer jacket manufacturing services. Look for attention to detail and quality throughout the process.

Ready to begin your puffer jacket project? Contact us for top-notch fabrics and expert guidance.