Corporate apparel serves as a mobile branding platform, directly influencing brand perception and employee engagement. Professionally engineered business shirts reinforce organizational identity while meeting functional demands across industries.

Strategic Design Framework

Effective corporate tee design integrates brand guidelines with technical specifications:

- Brand DNA Integration: Logo placement scaling ratios (1:10 chest-to-garment ratio)

- Color System: PMS matching with ΔE≤2 tolerance

- Typography: Minimum 8pt font for readability

- Imagery: 300dpi resolution for print clarity

Demographic and industry considerations require specialized approaches:

- Age Cohort: Millennials prefer modern cuts; Gen X favors classic silhouettes

- Gender-Specific: Contoured vs. straight fits with 7-12cm differential

- Industry Compliance: Healthcare requires antimicrobial finishes; construction needs high-visibility options

Technical Implementation

Color & Brand Identity

Color psychology impacts brand recall: Blue (trust) dominates 53% of corporate brands. Sublimated prints maintain color accuracy through 50+ washes when executed via Ludyway’s Sublimation Printing Services.

Typography Engineering

Font selection affects legibility: Sans-serif (Helvetica) maximizes readability at distance. Embossed lettering adds 0.8mm depth for tactile branding.

Performance Fabrics

Industry-specific fabric selection:

| Industry | Fabric | Weight | Features |

|---|---|---|---|

| Hospitality | Poly-cotton blend | 160-180gsm | Wrinkle-resistant |

| Construction | Ripstop polyester | 210-240gsm | Abrasion-resistant |

| Tech | Micro-modal | 130-150gsm | Moisture-wicking |

Precision Sizing

Global sizing compliance requires ASTM/ISO grading. Ludyway’s Custom T-Shirt Manufacturer division offers 12-size matrices with 3D fit mapping.

Design Portfolio

Subtle Branding

- Tone-on-tone embroidery (0.3mm stitch density)

- Sleeve taping with 1.5cm wide branding

- Neck label customization

Typography Systems

- Die-cut vinyl lettering (0.5mm raised effect)

- Reflective ink applications for safety sectors

Pattern Integration

- Seam-to-seam repeats at 30cm intervals

- Pixelated brand elements at 120ppi resolution

Structured Styles

- Twilled cotton (140-160gsm) with double-needle stitching

- Custom collar stays with laser-etched branding

Performance Polos

- Jacquard-knit collars with color-blocked panels

- 3-button placket with hidden snap closures

Technical Apparel

- ANSI-compliant reflective striping

- Mesh ventilation zones with 40% airflow increase

Production Best Practices

Strategic Brand Placement

- Left Chest: 8-10cm below shoulder seam, 3-5cm from center

- Full Back: 15-18cm below collar, centered alignment

Embroidery Specifications

- 40,000-60,000 stitches for 10cm logos

- Underlay stitching at 45° angle for stability

Printing Techniques

- Discharge printing for vintage effects

- High-density ink (1.2mm) for tactile logos

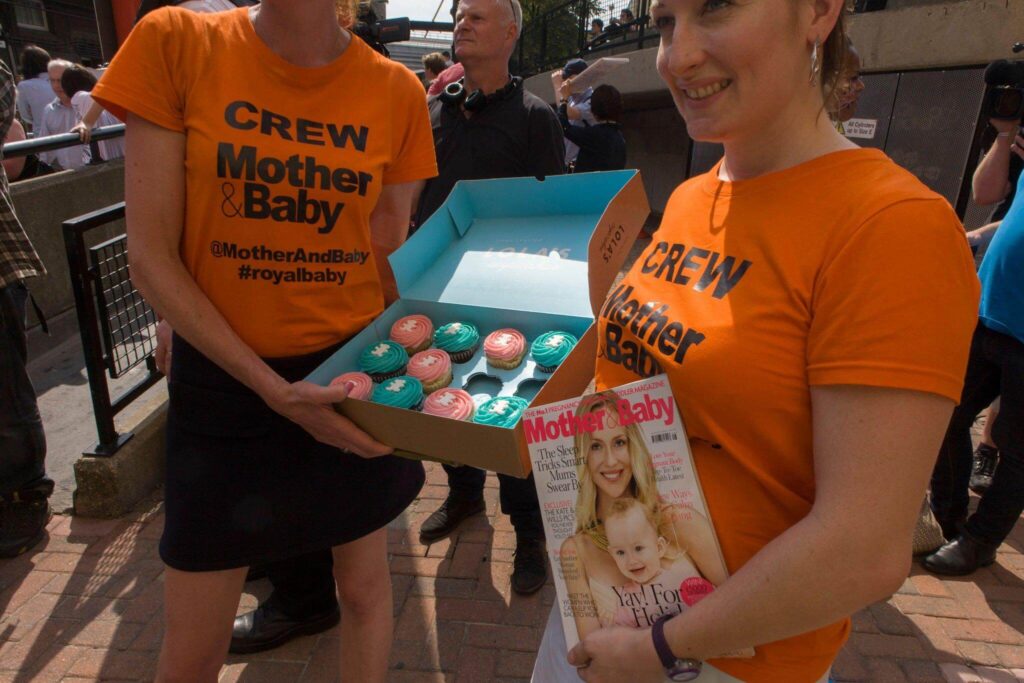

Call-to-Action Integration

- QR codes (2×2cm minimum) with 30% quiet zone

- Shortened URLs (max 18 characters)

Conclusion

Corporate apparel engineering balances brand visibility, wearer comfort, and production feasibility. From minimalist polos to technical performance wear, each design requires specialized fabric engineering and decoration techniques. Ludyway delivers turnkey solutions through integrated Private Label Clothing programs and Clothing Embroidery services. For technical specifications or bulk production quotes, contact info@ludyway.com.