Taslan fabrics are well-known for their versatility and durability. It is a popular choice for outdoor and performance apparel, including footwear, pants, jackets, and other types of outerwear. These garments are designed for activities such as skiing, hiking, and camping.

In the 1940s, the American textile company DuPont created the fabric for the first time. It was designed to provide durable and water-resistant garments for military and outdoor applications.

Since then, advancements in textile technology have facilitated further improvements in this fabric. Taslan fabrics are versatile and dependable materials that are highly valued by both designers and outdoor enthusiasts.

What Is Taslan Fabric?

Taslan fabric is typically made from polyester, nylon, or a blend of both fibers. The fabric is created using a specific weaving technique called “taslanizing.”. This technique involves using a special textured yarn.

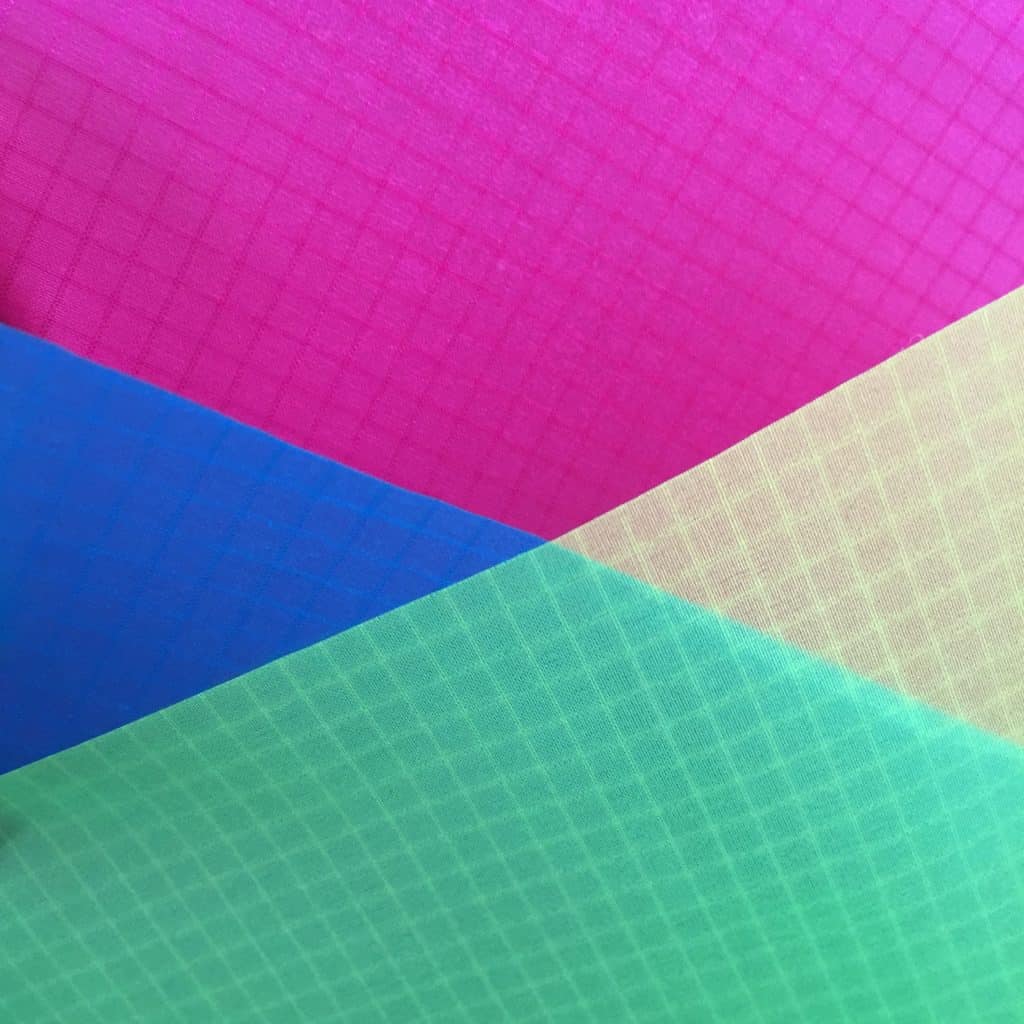

This type of fabric is known for its distinct texture and appearance, achieved through high-temperature treatments or specialized texturing machinery.

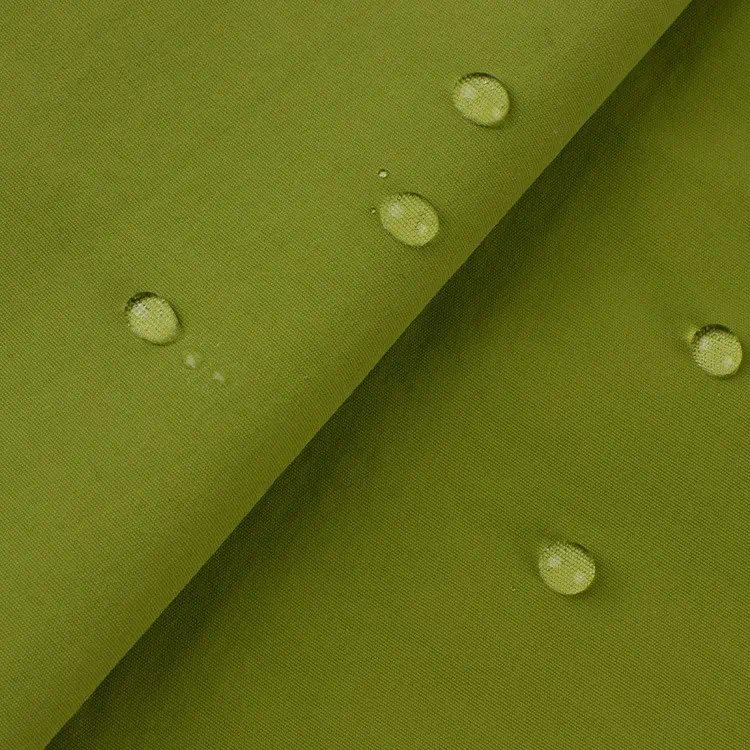

It is also known for its durability and resistance to water, making it a popular choice for outdoor clothing and gear.

Characteristics of Taslan Fabrics

The taslan fabrics have the following distinctive characteristics that contribute to its popularity and practicality:

- Durability

- Water Resistance

- Quick-drying

- Color Fastness

- Breathability

- Lightweight

Taslan fabrics are strong and durable, with a high strength-to-weight ratio that is perfect for performance apparel that requires durability and freedom of movement without added bulk.

How Taslan Fabrics are Made

The manufacturing process for taslan fabrics varies depending on the specific manufacturer and the desired properties of the fabric.

However, the key steps generally involve texturizing the fibers, spinning them into yarn, weaving the yarns in a specific pattern, and applying finishing treatments to enhance the fabric’s performance and aesthetics.

Taslan textiles are made through specialized weaving techniques that use synthetic fibers such as polyester or nylon.

- The yarns are texturized first through heat treatments. Specialized texturing machinery is also used.

- The texturized synthetic fibers are spun into yarns of various thicknesses and strengths. Multiple yarns may be combined to create different effects.

- Once the yarn is ready, it undergoes the weaving process to form the taslan fabrics.

- After the fabric is woven, it goes through various finishing treatments to enhance its properties. These treatments can include waterproofing or water-repellent coatings, UV protection, and anti-microbial treatments.

Uses of Taslan Fabrics

Taslan fabrics have diverse applications in various industries due to their good characteristics. Here are some common uses of the fabric:

● Outdoor Clothing and Sportswear

Taslan textiles are commonly used in outdoor clothing, sportswear, and activewear for their water resistance, breathability, and durability. These are also found in jackets, pants, parkas, raincoats, athletic shorts, shirts, tracksuits, and performance-oriented outerwear. Taslan provides comfort and protection during rigorous physical activities and outdoor sports.

● Footwear

Taslan fabrics are used in footwear for their water resistance and durability, which help keep feet dry and protected in wet or rugged conditions.

● Upholstery and Home Textiles

This fabric is durable and commonly used for furniture and car interiors. It can withstand frequent use while still maintaining its appearance. This fabric can also be used for home textiles like curtains, pillows, and bedding.

● Travel and protective Gears

Taslan fabrics are versatile. It can be used in luggage, suitcases, travel bags, and accessories like toiletry bags. It is also great for workwear, safety garments, and protective covers, keeping workers comfortable and protected in different industries.

How to Clean and Care for Taslan Fabrics?

To prolong the life of taslan fabrics, machine wash the fabrics using a gentle or delicate cycle with cold or lukewarm water, and avoid harsh detergents or bleach that could damage the fabrics.

Dry the fabric using low heat or air-dry settings, as high heat or direct sunlight could cause damage.

This fabric is typically wrinkle-resistant, but if necessary, iron on a low or synthetic setting with a pressing cloth or use a steamer for wrinkle removal without direct contact with the fabric.

FAQ

Is Taslan stretchable?

Taslan isn’t typically stretchable but can be made elastic by incorporating spandex or elastane. This enhances flexibility and freedom of movement.

Is Taslan good for cold weather?

Taslan fabrics are a great option for cold weather. It repels water and wind, acting as a barrier against both. It can also be combined with insulation for extra warmth.

What is the texture of Taslan fabric?

Taslan fabrics have a rough, grainy texture from their unique weaving technique. This texture serves both functional and aesthetic purposes.

What is a Taslan jacket?

A taslan jacket offers protection, durability, and comfort in various styles, including parkas, rain jackets, windbreakers, and lightweight jackets for different weather and activities.

Is Taslan fabric waterproof?

Taslan fabrics repel water and keep the wearer dry in light to moderate rain. However, it is not completely waterproof, and prolonged exposure to heavy rain may lead to some moisture seeping through the fabric.

Conclusion

Taslan is a synthetic textile known for its durability, water resistance, and texture. The fabric provides comfort, protection, and long-lasting performance. Thus, it is a popular choice in various industries and for outdoor enthusiasts. Proper care and maintenance can help prolong the lifespan and performance of the fabric.

The importance of taslan fabrics lies in their ability to provide durable, water-resistant, breathable, and versatile solutions across different industries. Its combination of functional properties and aesthetic appeal makes it a preferred choice for numerous products.