When delving into the world of ladies’ top manufacturing, a multitude of critical factors must be taken into account to establish a seamless and highly efficient production process. Every stage is pivotal in determining the quality of the final product, from the initial selection of high-quality materials to ensuring precise measurements and accurate cuts.

✨ Tees vs. Ladies’ Tops: Decoding the Difference

While both tees and ladies’ tops are wardrobe essentials, they offer distinctly different vibes. Think of the classic T-shirt as the laid-back, crew-neck staple, typically featuring short sleeves and prioritizing comfort. In contrast, ladies’ tops represent a broader, more fashionable category. These garments are characterized by a diverse array of shapes, sizes, and design elements such as intricate pleats, elegant ruffles, and varying necklines, all designed to help women express their unique sense of style.

This comprehensive guide will immerse you in the fascinating world of women’s top manufacturing. You will gain invaluable insights into every phase of the process, transforming an initial creative concept into a beautifully finished garment.

Understanding the Ladies’ Top Manufacturing Process

Crafting a stunning lady’s top is a unique synergy of artistic creativity and technical expertise. The process begins with Designers who conceptualize the initial idea, sketch styles, and meticulously select visually appealing and performance-ready fabrics. The critical next step involves Skilled Pattern Makers, who are essential in bridging the gap between design and reality. They translate the initial sketches into precise, technical blueprints, ensuring that each garment is structured to fit and flatter the female form perfectly.

Once the patterns are finalized, the professional clothing manufacturer team takes the lead. Highly trained technicians proceed to meticulously cut the fabric, adhering strictly to the precise patterns. Following this, the pieces are expertly assembled, with necessary details—such as custom buttons, zippers, or unique embellishments—being incorporated. The final, yet crucial, step is a rigorous quality check to ensure the top is flawless before it is prepared for its journey to fashion-forward consumers.

This collaborative effort, from the initial creative spark to the final product, is what brings the vast diversity and style of ladies’ tops to life. It requires a high degree of expertise, unwavering precision, and a genuine passion for translating your unique design vision into a tangible reality.

Designing the Perfect Women’s Top: From Concept to Blueprint

The versatility of a well-designed ladies’ top is unmatched. Whether it’s a timeless, elegant blouse or a modern, trendy crop top, these pieces come in an endless variety of shapes and styles. They are the ultimate canvas for self-expression, easily dressed up for formal events or work, styled down for casual outings, or layered for added warmth and fashion flair.

However, before this blank canvas becomes a statement piece, it undergoes a structured design and development process that strategically merges creative concepts with specialized technical skills.

💡 Key Steps in Designing a Women’s Top

Designing a ladies’ top is a creative process driven by clear objectives and inspiration. Start by defining your goals:

- Target Audience Identification: Determine precisely who this top is for. What is their lifestyle and aesthetic?

- Design Message: What feeling, message, or style do you want the top to convey?

Once your target and purpose are clear, the brainstorming and development phase begins:

- Conceptual Sketching: Sketch your ideal top or partner with a professional designer. The possibilities range from a classic, enduring blouse to a cutting-edge cropped silhouette.

- Detail Customization: Personalize your design with the perfect neckline, sleeve style, and any specific finishing details (e.g., pocket placement, unique closures).

- Production Planning: After the design is finalized, explore the best printing options or production methods to bring your unique creation to life with exceptional fidelity.

Exploring the Diverse Types of Ladies’ Tops

Ready to significantly upgrade your top inventory? T-shirts are merely the starting point! The universe of ladies’ tops is brimming with styles, fabrics, and design possibilities. Let’s explore some of the most popular varieties to help you identify the perfect match for your brand’s aesthetic.

Core T-Shirt Variations

- Fitted T-shirts: Available in superslim, slim, or boxy cuts, these styles hug the body to create a sleek, streamlined silhouette.

- Cropped and High-Low T-shirts: These are contemporary options that may showcase the midriff (cropped) or feature a dynamic, asymmetrical hemline (high-low) for a modern, edgy touch.

- Longline T-shirts: Characterized by an extended length, providing extra coverage and enhanced versatility for pairing with leggings or skinny jeans.

- Oversized T-shirts: Offering a completely relaxed fit, these are ideal for ultimate casual comfort and are excellent for layering.

- Graphic T-shirts: Feature bold prints, logos, or unique designs, serving as a powerful medium for self-expression and showcasing brand individuality.

- Neckline Variations: Styles like the V-neck, scoop neck, and off-the-shoulder offer different looks that can enhance various body shapes and provide aesthetic variety.

Beyond the Tee: Fashion Tops and Blouses

Moving beyond the basic tee, the category expands to include a wide variety of fashionable tops:

- Peplum Tops: These feature a flouncy, gathered detail at the waist, which adds a distinct touch of femininity and tailored style.

- Wrap Tops: Designed with overlapping fabric, they create an incredibly flattering, adjustable, and comfortable silhouette.

- Tank Tops and Camisoles: Essential sleeveless options, perfect for warmer climates or as versatile layering pieces for a cool, comfortable fit.

- Halter Neck Tops: These tops feature straps that connect around the back of the neck, offering a unique, stylish, and often sophisticated look.

This extensive selection enables you to design unique pieces that cater to diverse customer preferences and needs. Remember, when working with a skilled clothing manufacturer, the creative possibilities for crafting the perfect ladies’ top are genuinely endless!

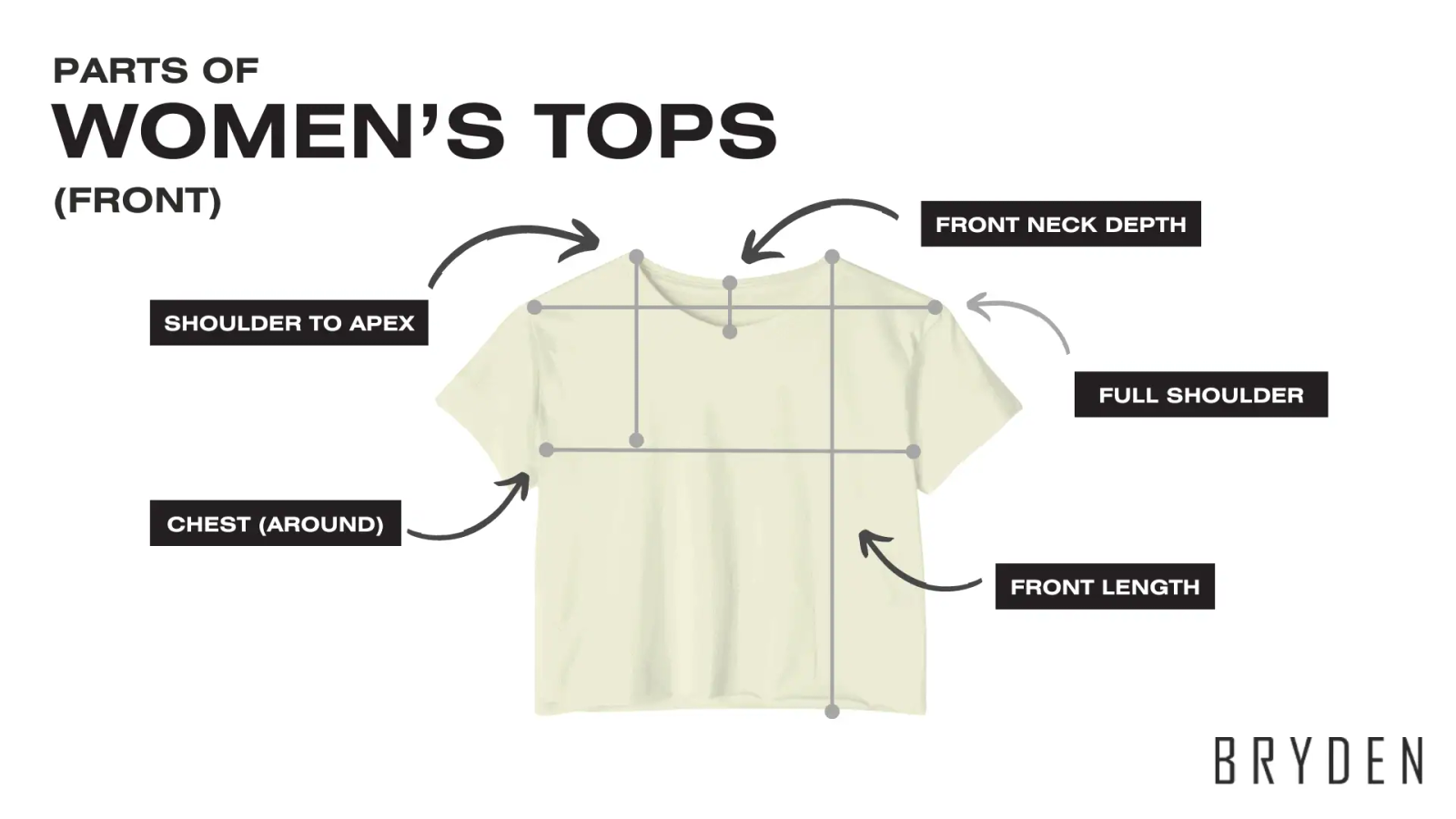

The Technical Anatomy of a Garment: Understanding Women’s Tops

Did you know that the distinct components of a top play a massive role in its comfort, fit, and overall style? A foundational understanding of these key garment parts is essential for both designers and manufacturers to ensure a premium product.

Essential Parts of Women’s Tops

| Component | Function and Styles |

|---|---|

| Neckline | Frames the face; styles include crewneck, V-neck, scoop neck, and more complex designs. |

| Bodice | Forms the main body of the top; can be fitted, loose, or feature shaping details like pleats or gathers. |

| Sleeves & Cuffs | Vary in length (short to long) and style (puffy, fitted). Cuffs finish the ends, often with buttons or elastic. |

| Armhole & Shoulder Seam | The armhole allows for movement. The shoulder seam connects the bodice to the sleeve/shoulder area. |

| Darts | V-shaped, sewn folds that are crucial for creating a tailored fit and enhancing the overall silhouette. |

| Hem | The bottom edge of the top; can be straight, curved, or deliberately asymmetrical. |

Designers leverage this technical knowledge to create precise patterns, while expert top manufacturers utilize it to construct the garment correctly. This harmonious integration ensures a comfortable, durable, and exceptionally well-fitting top for every customer.

Selecting Quality Fabrics for Women’s Top Production

The textile you select is the single most important factor influencing the look, drape, feel, and performance of your ladies’ top. Understanding the properties of common garment fabrics is essential for making informed decisions. Here are some of the most popular fabrics utilized in women’s top manufacturing:

🌿 Natural Fibers and Their Blends

- Cotton: The perennial champion of comfort. It is a natural, soft, and highly breathable fabric that is easy to care for and incredibly versatile.

- Linen: A strong, natural fiber fabric, prized for its cool and crisp hand-feel. While it wrinkles easily, it softens beautifully with regular washing.

- Silk: A luxurious natural fiber known for its soft, smooth texture and beautiful drape. It provides a high-end look but requires delicate, careful maintenance.

- Bamboo: An excellent choice if you are seeking a sustainable, breathable fabric that naturally wicks away moisture, making it comfortable for daily wear.

🧪 Man-Made & Blended Materials

- Polyester: A durable, versatile synthetic fiber, renowned for its wrinkle-resistant properties. It is often blended with other fibers to modify texture and functionality.

- Rayon: A man-made fabric with a soft, beautiful drape, often resembling silk. Its breathability and absorbency make it a great option for warm weather tops.

- Modal: Considered Rayon’s superior, ultra-smooth counterpart. Its exceptional softness and high absorbency make it comfortable for extended, everyday use.

- Tencel (Lyocell): A brand of rayon derived from wood pulp, highly popular due to its softness, inherent strength, and strong sustainability credentials.

- Jersey: A knit fabric that is soft, stretchy, and exceptionally comfortable. It is a fundamental fabric for casual tops, including T-shirts.

Understanding these diverse textile options empowers you to select the perfect fabric that aligns with your design vision, performance requirements, and desired customer experience.

Precision Pattern-Making and Fabric Cutting

Before any fabric is transformed into a fashionable top, it undergoes the meticulous processes of pattern-making and cutting. This crucial stage is the foundation that ensures each garment piece fits flawlessly, flatters the wearer’s silhouette, and maintains sizing consistency.

Creating a Precise Template

Pattern makers are skilled artisans who translate design concepts into technical blueprints. They factor in elements like “garment ease” (the allowance for comfortable movement) and “drape” (how the fabric falls on the body). This technical expertise is vital for achieving a perfect fit and a professionally polished finished product.

Pattern Customization and Development

Many professional top manufacturers offer an array of foundational patterns that can be readily customized for different styles and size ranges. If you have a unique vision, they can either work directly with your existing patterns or provide specialized services to develop brand-new patterns tailored to your exact specifications.

Ensuring Perfect Alignment (Truing)

Once the pattern is finalized, it undergoes a process known as “truing” to confirm that all corresponding pieces align perfectly. This meticulous attention to detail at this early stage is absolutely critical for manufacturing a flawless final garment, minimizing later errors.

A high-quality pattern is undeniably the bedrock of a beautifully crafted top. By grasping the significance of this initial step, you gain valuable insight into the craftsmanship and quality assurance that underpin the ladies’ tops you bring to market.

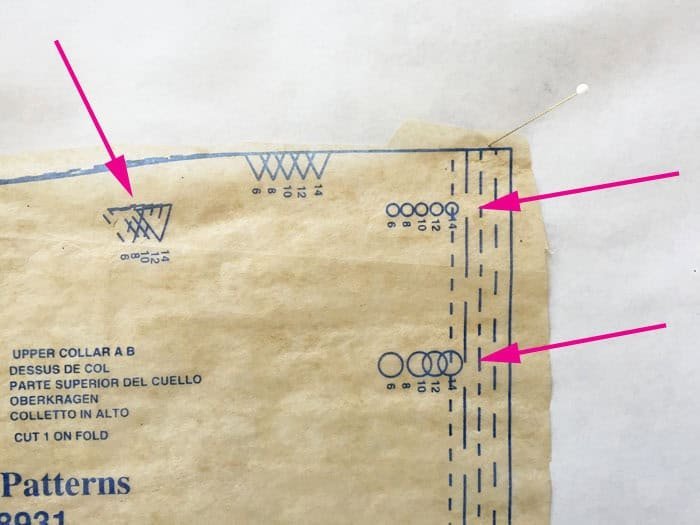

The Role of Accurate Marking in Pattern-Making

The pattern-making stage involves translating design ideas into precise templates, ensuring every piece fits together seamlessly. A vital component of this process is accurate marking. Without proper markings on the fabric, accurate cutting and subsequent sewing become nearly impossible.

Source: Craftsy

These markings act as the essential guide for the manufacturing team, guaranteeing that pieces align perfectly during the sewing process. Skilled technicians use a variety of tools, including marking pens, tailor’s chalk, and specialized rulers, to precisely transfer all necessary pattern details onto the fabric.

For instance, marking darts (the pointed folds that shape the bust or waist) ensures a clean, flattering fit. Similarly, correctly marking buttonholes and button placements guarantees precise alignment and proper functionality of the finished top. Crucially, accurate marking is also a key component of minimizing fabric waste, leading to more sustainable and economically efficient fabric utilization.

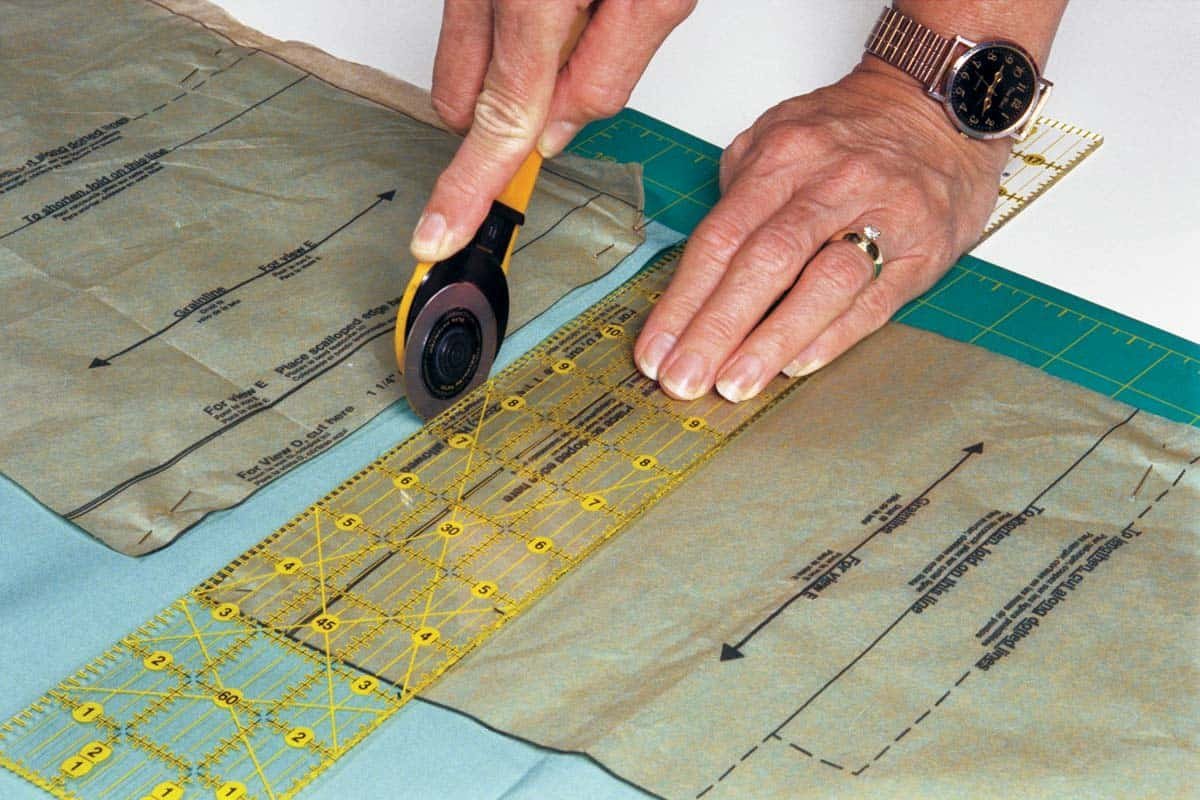

From Pattern to Product: Cutting and Sewing Women’s Tops

With the marked pattern as the detailed roadmap, the top manufacturer proceeds to meticulously cut the fabric pieces. Each component is carefully shaped to ensure they interlock perfectly, like puzzle pieces, to form the final garment structure. In this stage, precision is paramount, as even slight deviations can negatively impact the final fit and overall aesthetic appeal of the top.

Source: Threads

Following the cutting process comes the assembly stage: sewing. Experienced seamstresses carefully bring the individual pieces together, stitching them with high accuracy and consistency. This pivotal moment transforms the flat pieces of fabric into a three-dimensional garment, effectively taking your design from a theoretical concept to a wearable, stylish reality.

Different Types of Seams for Ladies’ Tops

Seams are the unsung heroes of garment construction, providing strength, integrity, and a polished finish. In ladies’ top manufacturing, various seams are employed, each offering distinct advantages:

- Plain Seam: The most fundamental and common seam, used for basic construction, creating a neat and secure join between two fabric pieces.

- French Seam: An exquisite, enclosed seam that effectively hides all raw fabric edges inside the garment. It is often used for sheer or delicate fabrics, providing a professional and highly durable finish.

- Flat-Felled Seam: A notably strong and durable seam, featuring two folded edges stitched flat. It is perfect for areas of the garment that experience high stress, such as side seams or pockets.

- Construction Seams: A broad term covering various specialized seams used to join different parts, create shaping (like darts), or attach unique trims and embellishments.

Selecting the appropriate seam type is essential to ensure that your ladies’ tops are not only aesthetically appealing but also comfortable, functional, and engineered for long-lasting wear.

Key Measurement Points for a Flawless Women’s Top Fit

Understanding and utilizing key measurement points is absolutely vital for crafting ladies’ tops with a consistently flawless fit. These precise points serve as the essential roadmap for the pattern-making and grading process, dictating how the final garment will drape and flow across various body shapes.

Different top styles necessitate different measurement priorities. For example, a fitted T-shirt will heavily focus on precise measurements for the bust, waist, and hips to achieve a close and comfortable contouring fit. Conversely, a loose-fitting blouse might place greater emphasis on shoulder width, sleeve length, and overall body length to achieve a relaxed, yet intentional, look.

By accurately incorporating these key points, professional clothing manufacturer partners can create reliable, consistent sizing charts that ensure a perfect fit across all styles and sizes offered. This level of consistency instills confidence in your brand and guarantees that the top will fit and look spectacular on your customers.

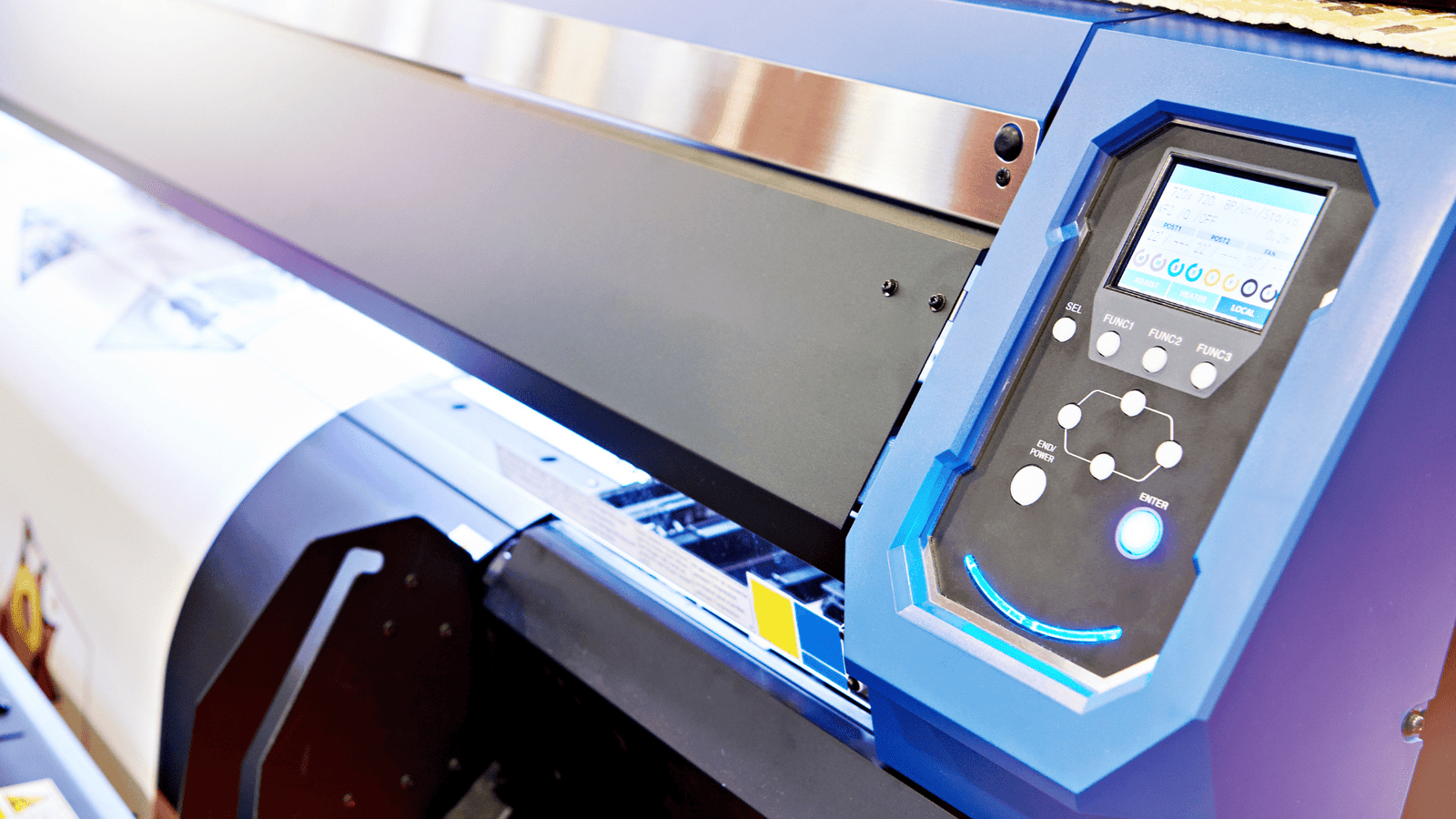

The Art of Garment Printing and Embellishment

Once a top is meticulously crafted, its visual appeal can be significantly enhanced through the dynamic processes of printing and embellishment. This allows for the incorporation of logos, complex designs, or unique patterns, adding a personalized, custom touch that brings your creative vision fully to life. Here are some of the most popular printing techniques available:

1. Screen Printing: Bold and Durable

Screen printing uses stencils to apply thick, vibrant layers of color onto the fabric, creating crisp, highly durable, and long-lasting designs. It is the go-to choice for bold, eye-catching graphics and is particularly durable and cost-effective for large-volume production runs.

2. Direct-to-Garment (DTG) Printing: Photo-Realistic Detail

DTG acts like a high-resolution digital printer for apparel. It uses specialized inks applied directly to the fabric, allowing for intricate details and photo-realistic images with an extensive range of vibrant color options. It is best suited for smaller batches or designs with high complexity.

3. Dye Sublimation: Seamless, All-Over Prints

This heat-transfer process permanently transforms solid dye into a gas, infusing it directly into the fabric fibers. It creates a vibrant, seamless look, ideal for all-over prints or designs that need to blend perfectly with polyester-based materials.

4. Heat Transfer: Versatile Application

Designs are pre-printed onto a special film, then adhered to the garment using heat and pressure—similar to applying a high-quality sticker. This method is highly versatile for various materials and applications, from simple logos to more complex, multi-colored designs.

5. Embroidery: Elegant and Dimensional

This classic technique adds a touch of elegance and tactile dimension using threads stitched directly onto the fabric. Embroidery is fantastic for high-quality, durable logos or patterns, giving your top a sophisticated, timeless, and luxury aesthetic.

Your choice of technique will depend on your design’s complexity, desired visual effect, and budget. Partnering with a skilled clothing manufacturer ensures you receive the best recommendation to execute your unique top design flawlessly.

Specialized Garment Finishing Techniques: Washing and Dyeing

Garment washing goes beyond simple cleaning; it is a finishing technique used to achieve a specific hand-feel, aesthetic, or distressed look.

- For Delicate Fabrics (e.g., Silk, Rayon): These materials require a gentle touch, ideally handwashing in cold water with mild detergent to protect delicate fibers from shrinking or fading.

- For Sturdier Fabrics (e.g., Cotton, Linen): A gentle machine cycle with cold water is generally suitable, though the care label should always be confirmed. Gentle washing significantly extends the lifespan of your tops!

Advanced Garment Washing Techniques

- Enzyme Washing: Uses enzymes to break down fabric fibers for an incredibly soft, broken-in feel, popular for achieving a worn look.

- Stone Washing: Typically used on denim, this technique employs pumice stones to create a vintage and casual, distressed aesthetic.

- Bleach Washing: Used to create a distinct, faded or lightened effect on tops and other apparel.

- Acid Washing: Often used to achieve a distinctive, edgy look with high-contrast fading patterns.

- Sand Washing: Utilizes sand particles to generate a gentle worn-out effect on the fabric’s surface.

Fabric Dyeing Techniques for Color Consistency

Manufacturers offer various fabric dyeing techniques to achieve vibrant and consistent colors:

- Yarn Dyeing: The individual threads are dyed before they are woven into the fabric. This method ensures that colors are consistent and deeply vibrant throughout the entire garment structure.

- Piece Dyeing: The fabric is dyed after it has been woven. This technique offers greater flexibility, allowing for a creative application of solid colors, bold prints, or intricate patterns on a single top style.

Selecting the correct dyeing method is crucial for achieving the exact color and design integrity you envision for your tops.

Rigorous Quality Control and Final Presentation

At every phase of the manufacturing process, we prioritize meticulous quality control (QC) measures. This commitment ensures that each ladies’ top not only meets our own high standards but also strictly adheres to your precise design specifications.

We thoroughly inspect every garment for stitching irregularities, fabric flaws, or any other imperfections. A crucial aspect of QC is sizing and fitting. We employ standardized size charts and fitting models to guarantee that all tops are consistently sized and fit well across the entire size range. This ensures your customers can purchase with confidence, knowing the top will look and feel great.

Packaging and Branding

The production journey concludes with a final, vital step: professional packaging and branding, which contribute significantly to the customer’s first impression.

- Packaging Options: We offer a range of options, from simple, elegant poly bags to custom-branded boxes. The choice allows you to select a presentation that best reflects your unique brand identity.

- Labeling and Tags: We ensure the inclusion of professional labels and tags that prominently display your brand logo and clear care instructions. This provides essential product information and powerfully reinforces your brand identity at every customer touchpoint.

By combining high-quality manufacturing with thoughtful packaging, we help you deliver a complete, professional product that truly delights your customers.

Conclusion: Partnering for Success in Women’s Apparel

The journey of transforming a creative fashion vision into a wearable reality is a rewarding one. From the initial design concept to the final, beautifully crafted top, a reliable clothing manufacturer is your essential partner every step of the way. Whether you are launching a new brand or are an established designer, achieving the perfect fit and seeing your designs realized in high-quality is the ultimate goal.

Our team of experts works in close collaboration with you to ensure that your ladies’ tops are both stunning and exceptionally comfortable. We are dedicated to creating garments that flatter every body type, ensuring your customers feel both confident and stylish in your apparel.

Ready to transform your dream top designs into a tangible success?

Contact us today and let’s discuss bringing your vision to life!

❓ Frequently Asked Questions (FAQ) About Top Manufacturing

Q1: What is the difference between a T-shirt and a ladies’ top in manufacturing?

A: While a T-shirt is generally a basic, crew-neck, short-sleeved staple, a ladies’ top is a much broader category. Ladies’ tops encompass a wider variety of fashion elements, including varied necklines (V-neck, scoop), unique structural details (peplums, ruffles), and diverse silhouettes (wrap, fitted, oversized), requiring more complex pattern-making.

Q2: Why is pattern-making so crucial in top manufacturing?

A: Pattern-making is the foundation of the garment. It translates the 2D design into a 3D blueprint, factoring in garment ease, drape, and body fit. A precise pattern ensures consistent sizing, minimizes fabric waste, and guarantees the final top fits and flatters the wearer correctly.

Q3: Which printing technique is best for a design with many colors and intricate detail?

A: Direct-to-Garment (DTG) printing is typically the best choice for designs with a high number of colors and intricate, photo-realistic details. It uses specialized digital inks to apply the design directly, offering excellent resolution and a full-color spectrum, though it may be less economical for extremely large batches compared to screen printing.

Q4: What are “darts” and what is their function?

A: Darts are V-shaped, sewn folds in the fabric. Their primary function is to remove excess flatness and build in a tailored, contoured shape to the garment, typically around the bust, waist, or hips. Darts are essential for creating a professional and well-fitting silhouette for women’s tops.

Q5: What is the most important factor when choosing a fabric for ladies’ tops?

A: The most important factor is a balance between the desired aesthetic (drape, texture) and functionality (comfort, breathability, durability). For instance, rayon offers great drape for a blouse, while cotton offers superior breathability for a casual top. Your final choice must align with the top’s intended use and your target market’s needs.