The jacket manufacturing industry is important for the fashion world because it serves as an accessory to become more stylish. Manufacturing a jacket has various processes and designs that suit the jacket for your brand.

Jackets have evolved beyond mere protection from the weather, they become an integral fashion identity for many, especially millennials.

In this comprehensive guide, we will discuss the different processes used for manufacturing jackets, their patterns, seams, and even the anatomy of jackets.

It is a common misperception that jackets and hoodies are just the same, but they are different in style. Hoodies typically do not have a zip but contain a hood. However, unlike most of these items, some jackets have hoods, while others do not.

By diving into this article, you will learn the necessary information you have to know if you plan to start your own jacket brand and how manufacturers of jackets can help you. Moreover, this article will also help you understand why jackets are trendsetters.

Understanding The Jacket Manufacturing

Source: Women’s Health

Jackets provide comfort and a sense of fashion. It comes in different styles with different fabrics suitable for specific seasons, and it has different cuts and details to suit your taste.

Furthermore, the primary purpose of manufacturing jackets is to provide garments that can protect you and give you comfort. In addition, jackets can be used as an accessory for another set of garments, like what we see in magazines.

If you are planning to start your brand centered on jackets, this article is for you. As you dig deeper into the content of this article, you’ll understand the essence of the jacket manufacturing industry.

How to design the perfect jacket?

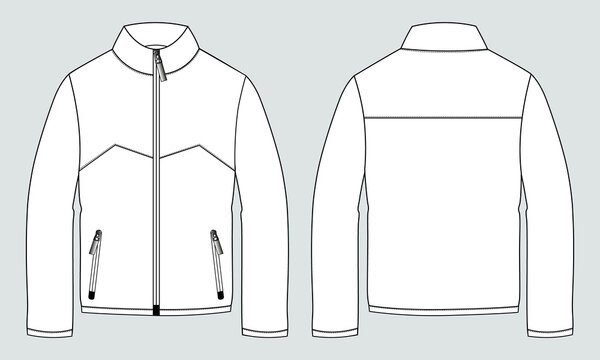

Source: Adobe Stock

Learning about how jackets are made gives you the freedom to have complete creative control over your jacket designs. You can bring your unique vision to life, from choosing the perfect fabrics and patterns to adding custom details like prints and logos.

Partnering with a jacket manufacturer lets you focus on your brand vision while they handle the production expertise. This frees you up to concentrate on marketing, sales, and other aspects of building your brand, without the added stress of managing a complex manufacturing process.

You need to understand that there are different types, cuts, and designs of jackets. And you have to think of something new that can make your brand stand out in the market.

Hence, these are the following steps you have to take note of in creating the perfect design for your jacket:

What are the steps for designing a perfect jacket?

One of the most important things about jacket manufacturing is the design. With that, here are the steps you need to keep in mind:

1. Establish your objectives

Before anything else, you have to establish your objectives. Think of the reasons why you want to ask for help from jacket manufacturing experts. Remember that your goal will serve as a guide for the manufacturer to properly create the design you want.

Moreover, you might as well ask yourself questions like:

- “What is the primary goal of my jacket design?”

- “Is the design suitable for the season?”

- “Is the design practical and cost-efficient?”

- “On what occasions can my customers wear this jacket?”

Moreover, open communication is important between you and your jacket manufacturer. Your jacket manufacturer can help you think of a way to lower the cost of production. Further, if you are not confident in your objectives, you can ask for the insights of your jacket manufacturer.

Lack of ideas and an unsure budget allocation for your brand are some of the reasons why you need the best jacket manufacturer.

2. Widen your view and apply your imagination

Once you’re done establishing your objectives, it is now time to use your imagination for your design.

Normally, people who are not art-inclined struggle with sketching. However, this can be solved with the help of a jacket manufacturer or jacket designer. With a jacket manufacturer, you can rest assured that all your ideas for your perfect jacket will not be wasted.

To start, try to ask yourself the following questions:

- “What color suits my skin tone?”

- “Should I add logos and words to it, or just a minimalist design?”

- “Is the design appropriate for the season I’m in?”

- “Can I match this design to my sandals and t-shirts?”

The most important part of conceptualizing your design is allowing your imagination to do its job. Be as creative and unique as possible, since you aim to create a design that can stand out in the market.

3. Sketch

Sketching is indeed a crucial step, which is why you have to carefully sketch your design. Additionally, for those startup business owners, we highly encourage them to use durable materials for their sketches.

Moreover, if you are not confident with your sketch and you think something is off, you might as well contact a designer who can help you.

4. Choose your fabric

Consider this step as a tip. Since every person has different skin types, you might as well raise it with your jacket manufacturer to get the perfect jacket. Indeed, open communication with your manufacturer is what you’ll need, particularly in this matter.

5. Decide who will design your jacket

With the right people, your dream will come true. In the manufacturing industry, you have to remember to set aside your doubts and learn to trust. Here are the platforms where you can find experts who can help you manufacture your jacket:

- Fiverr

- People Per Hour

Design your jacket with a customizable template

Technological innovations are just around the corner, so why not make use of them? To take advantage of your ideas, you can use customizable templates downloaded on your phone or laptop.

Once you gather all of them, you can now give them to your jacket manufacturer or the designer you hired.

Tips for designing the perfect Jacket

This section of the article aims to provide a comprehensive guide to help you make your way into the jacket manufacturing industry. With that, even the tips are provided here!

Get your pen and paper and start jotting down all the tips below:

1. Decide On The Placement

Source: Kick Print

The location of the logo plays a pivotal role in making the jacket look perfect. It is usual for makers of jackets to have their logos or designs on the front body, sleeve, back body, and even on the cuffs.

2. Pick The Color For Your Jacket

Colors attract attention, which is why choosing the best color for your jacket is important. Jacket manufacturers normally use one color for the jackets. However, to make your jacket unique, you can mix the colors and add them to your design.

If you are hesitant when it comes to picking the color, you can always ask for assistance from the jacket manufacturer you hired.

3. Add visuals and graphics

Source: Pinterest

To enhance the design of the jacket, you can make use of graphics and visuals. Make the fabric your canvas, and apply anything that comes to mind.

4. Make Use of Typography

Source: Pinterest

If you think graphics and visuals are overrated, why not try to use typography? You can ask your jacket manufacturer where the best placement is for the typography, which can highlight the jacket.

Further, you can also incorporate it into yourself. The market already has statement t-shirts, so why not create a jacket version of it?

8 types of jackets to add to your brand

You might get confused about what jacket is appropriate based on your gender. Worry no more because the following are the types of jackets suited for both genders:

1. Peacoat Jacket

Source: Pinterest

The peacoat jacket is a heavy wool jacket detailed with large buttons on the front. This type of jacket is perfect for winter and stormy seasons since it provides warmth. In addition, peacoat jackets are water resistant and perfect for a rainy season.

2. Blazer

Source: Pinterest

A blazer is a solid color jacket with metal buttons. This type of jacket has different styles and cuts suited for both males and females. If you need to attend casual events, go grab some blazers since they are naturally worn during casual events. Despite this feature being similar to a suit, a blazer is cut more casually.

3. Leather Jacket

Source: Pinterest

Leather jackets are a good addition to your brand! Black or brown dyed animal skin makes up a leather jacket which is usually trendy. This jacket was also known as a biker jacket in the early 1920s and it was designed for the US Air Corps during World War I.

If you want something warm that will last longer, then consider getting yourself a leather coat. Further, this can be worn during winter or autumn to go to casual or official ceremonies.

4. Trench Coat

Source: Pinterest

Trench coats are a type of jacket that can withstand the wind and rain. It is water resistant due to the fabric used for making it. Normally, trench coats have adjustable belts and flattering shapes.

In addition, this type of jacket is very popular with movie characters, who typically wear trench coats due to their cool vibe.

5. Duffle Jacket

Source: Peter Christian

A duffle jacket is made from duffle cloth and is characterized by toggles, pockets, and large hoods. It is primarily worn during the winter and for informal events.

6. Denim Jacket

Source: Pinterest

The fabric used to make denim jackets, as the name implies. Jacket manufacturers of these types of jackets use denim fabric because it is durable and easy to care for.

7. Parka Jacket

Source: Pinterest

A parka jacket is a padded coat during winter seasons and cold weather activities. Do not forget to take a parka jacket with you whenever you want to travel to the Arctic Circle. This way, it will ward off the heavy cold that would trigger an illness or actual cold.

Further, you can dig deeper into what parka jackets are by visiting the 9 types of Parka Jackets for men.

8. Cardigan

Source: Pinterest

One of the most popular types of jackets is the cardigan. It is made of a knitted sweater that has an opening in the front, and it may come with a button or zipper.

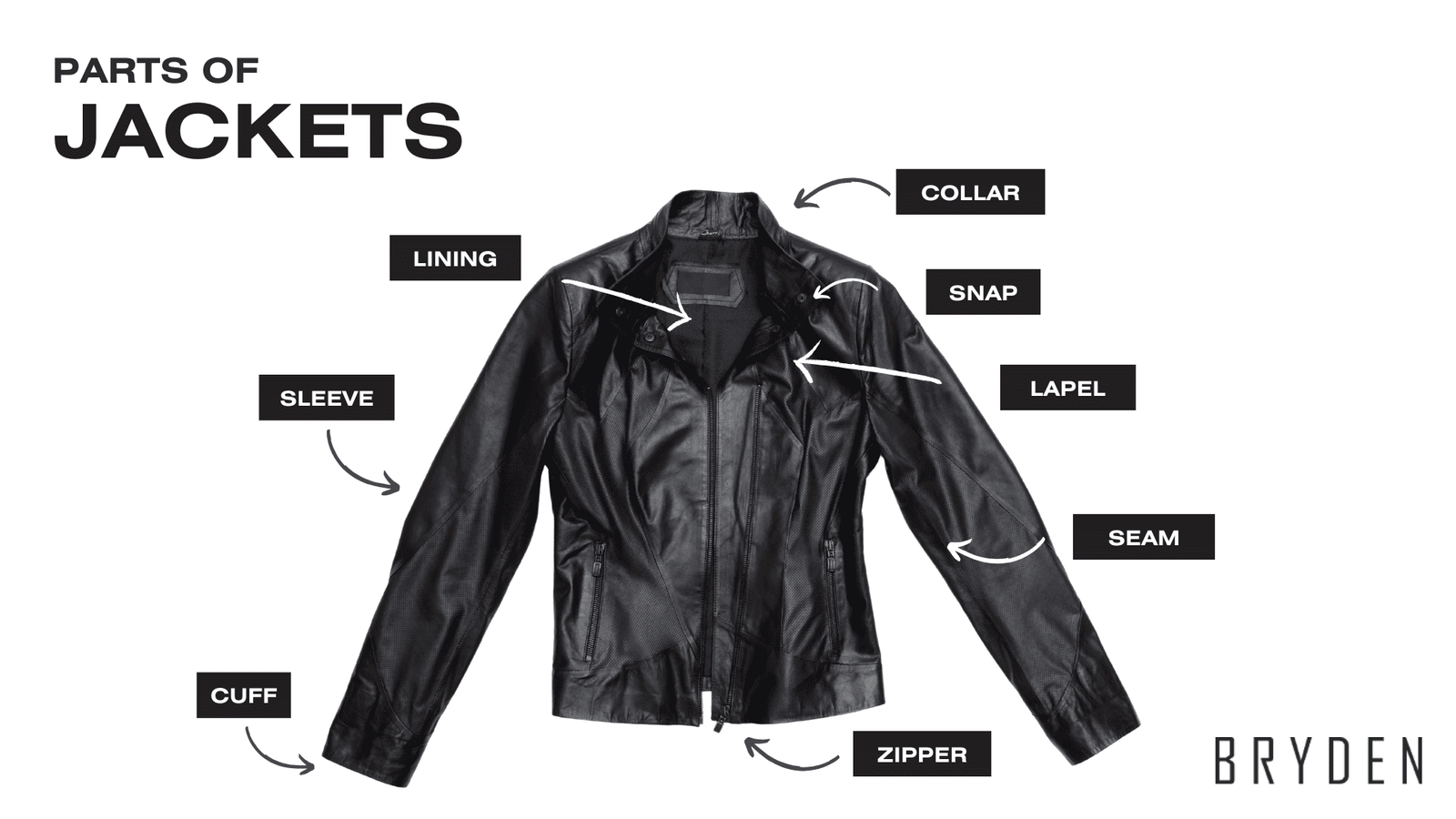

Anatomy Of Jacket That Jacket Manufacturers Consider

The jacket manufacturers as well as the designers make use of each part of the jacket. They are aware that the parts of the jacket may vary depending on what they will make.

With that, you need to emphasize to your manufacturer what you want to add to your product so that the manufacturer can list down the parts of the jacket needed.

What fabrics do jacket manufacturers use in manufacturing jackets?

Source: The Last Stitch

Jacket manufacturers carefully choose what fabric is most suitable for a certain type of jacket; this requires careful analysis and effort. Remember, the fabric is one of the foundations of the jacket, which is why the fabric must be perfectly matched with the design.

What is more, the manufacturers relate the material to the goals and designs given by their clients.

In regards to that, you ask your manufacturer to use a fabric that suits your taste and style. In that way, the jacket will be aligned with your personality.

To give you an overview, we prepared a list of normally used fabrics by manufacturers in making a jacket.

1. Polyester

This is often used to create coats and jackets since it is less expensive than the other fabrics. In addition, polyester has durable fibers that can make the jacket last a long. Choosing polyester is a good thing to do since you can have a durable jacket at a lesser cost.

2. Acetate

Acetate is made up of cellulose, which makes it smoother and softer than the other fabrics. Moreover, acetate is perfect for the lining of the jackets. However, acetate is a delicate fabric that needs to be properly taken care of, particularly in terms of how to wash it.

3. Silk

Unlike the others, silk is a delicate and expensive fabric. Normally, it is used to create high-end coats and jackets.

4. Cotton

Jacket manufacturers choose between Pima, organic, upland, and polycotton to make a jacket suited for summer. Due to the comfort and breathability of cotton, manufacturers consider it the perfect fabric for the warm season.

5. Linen

Linen is a lightweight fabric perfect for coats and jackets that are usually used in everyday chores. Further, it is durable and easy to dry up, which makes it perfect for jackets meant for outdoor activities.

6. Denim

Jacket manufacturers love to use denim fabric for manufacturing jackets due to its durability. Moreover, this fabric perfectly matches any design of the jacket, whether it has visuals or typography. This is why denim jackets are a part of many fashion styles.

7. Wool

Wool is a fabric that is commonly used for coats and jackets meant for winter. This fabric is thick and water-resistant. If you plan to add a jacket made of wool to your collection, you can choose between the following:

Cashmere Wool

This wool came from cashmere goats; it is considered a luxurious wool due to its rarity. Moreover, it is soft and warmer than the normal sheep wool used for jackets.

Cashmere wool comes from cashmere goats that can be found in China, Nepal, Mongolia, and India. Jacket manufacturers considered this a luxurious one due to its rarity. Further, cashmere wool is softer and warmer than the casual sheep wool.

Alpaca Wool

Alpaca wool comes from alpacas. If you have sensitive skin that can be triggered by fabric fibers, you might as well go for alpaca wool. This fabric has hypoallergenic properties that can protect the skin. In addition, alpaca wool offers warmth and a silky texture, making it perfect for manufacturing jackets.

How Does the Jacket Manufacturing Industry Make Patterns?

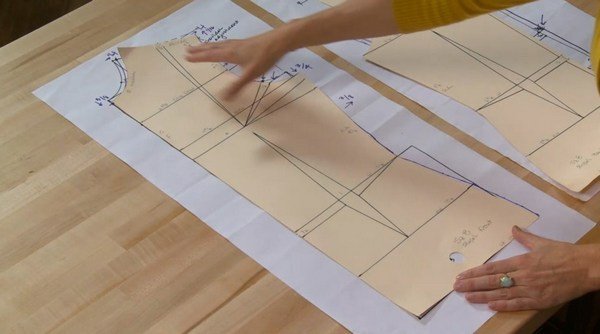

Source: Made/in

The jacket manufacturing industry uses patterns to make their jackets accurate and aligned to their designs. In your case, if you plan on starting your jacket collection, you have to make sure that you have the right pattern.

This is also the most essential duty of a jacket manufacturer so better hire the best one!

What is pattern making for a jacket?

Source: Bourne Crisp

Pattern-making serves as the stage where the blueprint for the jacket is created. Since this is somehow tricky, you indeed need a manufacturer to help you. Further, you have to remember that in making a pattern, all pattern pieces must be accurate and based on the measurements taken.

With that, here are the steps in pattern-making for a jacket:

1. Choose The Type Of Jacket

Source: Freepik

Like I said, choose the type of jacket you want your jacket manufacturer to create that best suits your brand. Try to consider the climate of your target audience location, height, and body figure.

2. Think Of A Design And Sketch it.

Source: Extreme Design

After deciding what type of jacket you want, it is now time to gather your ideas and create your design. Sketch your desired design and allow your mind to imagine. After you finish your sketch, you can add colors to it. That way, you can get a glimpse of the result you want.

After sketching, get your fabric, pins, rulers, French curves, and the marking tools essential for pattern making.

3. Take Accurate Measurement

Source: Canvas ETC

Normally, inaccurate measurements lead to the wrong pattern and size of the garment. It is essential to accurately get the measurements for your jacket. You have to make sure that you send to your manufacturer the accurate measurement to avoid wasting time and fabric.

However, if you are not confident enough to take your measurements, jacket manufacturers usually have standard measurements that they can use. This is also important since the manufacturer knows the ins and outs of body measurements.

4. Decide How To Make The Pattern

Source: ICF

There are 2 ways to make a pattern: Pattern drafting and Draping

Pattern Drafting

This is a method for creating basic blocks for your design based on specific body parts such as the waist, hip, thigh, knee, and leg.

Draping

This technique is a 3D technique that creates patterns by placing the fabric directly on the human body. It allows the manipulation of different fabrics to achieve different effects.

5. Add Details

To make the pattern accurate, the presence of curves and notches is important. Having these details can prevent misshapes that might affect the entire jacket.

6. Digitize Your Pattern

Once you have your pattern, you can reproduce it through an online copy. You can add a description, name, and price to it since you can sell it to other aspiring entrepreneurs.

Remember that the pattern must be accurate in any aspect. The pattern is the blueprint of the whole manufacturing process, which is why it has to be correct.

Marking Tips for Cutting Patterns on Fabric

With regards to the preparation for fabric cutting, here are the tips:

How Do Jacket Manufacturers Cut and Sew the Fabric?

Source: Adobe Stock

After drafting the pattern on the chosen fabric, it is now time to cut the fabric and later sew it. In this phase, the different cuts necessary for manufacturing jackets must be considered. Above all, the cutting tools needed for cutting and sewing the fabric must be properly prepared.

How do I cut a jacket?

Jacket manufacturing requires two specific ways of cutting, and these are the following:

1. Cutting The Pieces

It is a given that the jacket, like the other garments, has parts, and these parts can be cut separately to use the time efficiently. The following are the parts of the jacket that can be cut separately:

- Sleeve

- Colar

- Body

2. Cut According to Style

The second way is by cutting according to style. This involves consideration of the types of jackets since not all jackets have the same pattern of cutting. Further, the measurements of the jackets must be followed correctly to avoid miscuts that might affect the size and fit of the jacket.

How do I sew the jacket?

Source: The Daily Guardian

Sewing the fabric pieces together allows you to have an overview of the results of your design, pattern-making, and cutting.

Furthermore, here are the steps on how jacket manufacturers sew a jacket:

What Are the Different Types of Seams Jacket Manufacturers Use?

The pieces of fabric cannot be put together without seams. In the jacket manufacturing industry, seams may vary depending on what type of jacket you want to create.

Also, we want you to note that you can ask your jacket manufacturer to use different types of seams in one jacket. Doing so will strengthen the attachments between fabrics.

Hence, these are the different types of seams for jackets:

Plain seam

The most common type of seam is a plain seam; it’s all about putting two pieces of fabric together. You can use plain seam for jackets made up of linen, such as blazers.

Double-stitched seam

If your fabric is thick, you might as well use a double-stitched seam. It has the nature of strengthening the pieces of fabric, which is why it is commonly used for denim jackets and parka jackets.

Flat-felled seam

Another seam is needed if you want to have a long-lasting seam on the jacket. This seam is commonly used for thick fabrics such as denim, wool, and leather.

What are the measurement points for jackets?

The right measurements can prevent you from wasting money and manufacturing time. You can ask your jacket manufacturer to take your body measurements to ensure accurate measurements.

Further, if you plan on establishing your brand centered on a jacket, you also need to consider the standard sizing and measurements of the jacket for other people.

To highlight this, jacket manufacturers use these main measurement points as their foundation:

Taking measurements is a vital process in creating a jacket since this will be the basis for your accurate design. You have to keep in mind that one wrong measurement can ruin the jacket’s style and aesthetic.

The Printing Techniques Jacket Manufacturer Use

Jacket manufacturers use a wide range of methods to boost the uniqueness of jackets. You have to make sure that your jacket is unique and this is where having jacket designers is important

Moreover, the following are the printing techniques jacket manufacturers use to boost the style of a jacket:

1. Screen Printing

Source: T Shirt Plus

One of the most basic and oldest methods of printing designs onto fabric is what we call screen printing. This method uses an inkjet printer and ink with various colors. It also uses a tunnel dryer to secure the placement of the design.

Jacket manufacturers prefer this method of printing due to its longevity. However, this method causes fabrics to be rough and hard in texture since the ink dries together with the fabric, causing it to stiffen.

2. Embroidery

Source: Leslie Fehling

Have you seen a cardigan? You can notice the unique printing method that it has; that method is called embroidery. So, embroidery is all about using colorful thread to add the design to the jacket.

Further, this method also takes a longer time, unlike the others, since some embroidered garments, like cardigans, are handmade. On the other hand, embroidery machines can be used for this.

3. Heat Transfer

Source: Impact Northwest

This method is commonly used for leather jackets. This is all about transferring the dye through heat. Unfortunately, the designs created through heat transfer have a shorter lifespan than the other designs carried out through other methods.

4. Direct To Garment Printing (DTG)

Source: MonsterPrints

This method is up to date since it needs technology such as a digital printer. Basically, it is used for the easy and fast production of jackets.

It uses a specialized digital printer and ink. The design will enter the machine and be directly put into the fabric using ink. Imagine printing office documents with pictures on them; this method looks exactly like that.

Today, jacket manufacturing industries prefer to use DTG printing since it’s more convenient to use than the others. However, the design might be less durable than the other designs carried by the other methods.

What Are the Different Types of Garment Washing for Jackets?

Taking care of your jackets is important to extend their fabric and design lifespan. Here’s a list of types of garment washing for jackets.

1. Garment Wash

This is the most common type of washing for any garment. It is all about the normal process of washing, which includes the use of heat, water, detergent, and a washing machine.

2. Bleach Wash

Bleach wash uses a bleaching agent and water to clean the jacket. It can be associated with garment washing; however, unlike garment washing, bleach washing affects the design and texture of the fabric.

Make sure to add the washing procedures for the jacket in your packaging. This will help your customers take care of the jacket well to make it last longer.

Fabric Dyeing Techniques For Jacket

To elevate the design of your jacket, you can ask your jacket manufacturer to add dyes to it. Further, both of you can choose between the various dyeing techniques that will surely make your jacket interesting.

With that, take a look at the following fabric dyeing techniques you may use for your jacket:

1. Tie-dye

Source: Prima

The tie-dye technique involves twisting and tying fabrics and later squeezing a bottle of dye onto the fabric. This method allows the division of colors into the fabric; you can also use different colors for one garment.

2. Ice dye

Source: bp impex

The ice dyeing technique is all about letting the ice melt to resist the color distribution on the fabric. If you want a technique related to science, go for the ice dyeing technique.

3. Shibori

Source: Heddels

The shibori dyeing technique originated in Japan. It is about using resist dyeing with the use of bands and traditional motifs put into the fabric. After that process, the fabric will be put in the shibori bath and allowed to absorb the dye.

Quality Control Measures For the Jacket Manufacturing Industry

To manufacture high-quality jackets, their quality must meet the standard. The purpose of ensuring the quality of the jacket is to secure the loyalty of your customers. Of course, you don’t want to receive negative feedback from them. That is why your jacket must undergo different quality control tests.

With regards to that, these are the procedures to ensure the quality of your jacket:

- Evaluate the size and features of the jacket to see if it’s accurate to the pattern you created.

- Fabric testing and seam inspection are necessary to make sure the fabrics are properly intact. If the seam is tight enough to hold the fabric pieces and if the seam can last even in harsh conditions.

- Product design analysis to ensure that the design is accurate and that the color is right, particularly if dyeing techniques are involved.

Sizing and Fitting

A sizing and fitting test of the jacket is required to make sure that the jacket has an accurate measurement. This procedure might be time-consuming but it can help you ensure that your jacket meets quality standards when it comes to size and fitting.

Things to Remember in Packaging And Branding

Source: Textile Industry

Another factor that will make your jacket stand out is your packaging and branding. You have to create unique and eye-catching packaging for your brand.

Therefore, take a look at the following tips for packaging and branding:

- Labeling: Your jacket label should clearly display essential information like brand name, size, and care instructions. The design should be eye-catching and reflect your brand’s unique identity.

- Tags: Tags provide essential information to your customers and elevate the perceived value of your brand. Typically, a jacket tag includes the brand name, size, care instructions, and fabric content, ensuring that your customers have all the details they need to care for and appreciate their purchase.

- Packaging: The last stop is packaging; think of something convenient to use. Easy to carry and cost-efficient. Jackets are commonly packaged in poly bags to protect them from dust and moisture during transit and storage. These bags are often transparent, allowing customers to see the product without opening the packaging. For a more premium feel, some brands opt for branded boxes or garment bags, which can also be reused by customers for storage.

Jacket manufacturing demands skills, creativity, time, and funds, which is why some aspiring brand owners have a hard time with it. That is why we encourage you to reach out first to jacket manufacturers or designers in the jacket manufacturing industry. Through that, you can start your own brand with the right people by your side to guide and help you.

In Conclusion

Launching a successful jacket brand requires a combination of creativity, expertise, and meticulous attention to detail. By partnering with experienced jacket manufacturers, you can leverage their knowledge and resources to bring your brand vision to life.

Remember, building a brand takes time and effort, but with the right guidance and support, you can create a jacket collection that resonates with your target audience and stands out in the competitive fashion market.

With that, we are here to provide the support you’ll need. Don’t hesitate to contact us, and let’s make your brand successful.