Parkas are more than winter wear. They’re a commitment to staying warm and stylish. Precision-crafted, they offer unmatched protection against the cold. Each detail, from the fur-lined hoods to the robust materials, serves a purpose.

While jackets are versatile and lighter, parkas go the extra mile. They extend beyond the waist, providing enhanced coverage. Built to withstand extreme environments, parkas masterfully blend insulation with weather-resistant fabrics, ready to brave harsh conditions.

Curious about what goes into crafting these resilient yet stylish outerwear essentials? Explore the entire process of parka manufacturing—from initial patterns to the final product. Dive into the fascinating world of parka manufacturing!

Understanding parka manufacturing

Winter’s arrival calls for a reliable defense against the cold, and parkas are the perfect solution. Lined with cozy down or synthetic fibers and topped with insulated hoods, they combine warmth with style. Durability and design make parkas an essential companion in freezing temperatures.

Parkas have roots in the Inuit of Canada, where surviving icy conditions was a daily challenge. These garments were more than warmth—they embodied human resilience against nature’s harshest challenges. Over time, rugged essentials transformed into fashion statements, especially popular with vibrant colors and lighter materials.

Today’s parkas blend tradition with innovation. Unlike lighter jackets, parkas are built to tackle extreme cold with added insulation and length. Creating a parka demands specialized techniques, ensuring each piece is both durable and weatherproof. Quality control plays a critical role, as rigorous testing ensures every parka can withstand the toughest environments.

Designing the perfect parka

Creating the ideal parka involves a mix of creativity and strategy. The process goes beyond simply choosing materials and adding features. It’s about blending style, functionality, and market insights to craft a garment that truly stands out.

Steps on designing a parka

Let’s dive into the essential steps of designing a parka that excels in both form and function.

1. Crafting your vision and audience

Start by clarifying your design goals. Are you introducing a new style, enhancing an existing collection, or addressing a specific market need?

Decide if the parka will focus on classic warmth or incorporate cutting-edge features. Next, identify your target audience—consider their age, lifestyle, and the climate they live in.

2. Trendspotting and market exploration

Delve into current trends and market demands by exploring what’s popular in fashion. Investigate consumer preferences and analyze how competitors position their products in the market. Identify any market gaps that your design could fill.

Create a mood board with inspirational images, colors, and materials. This visual aid will guide the design process and ensure it aligns with contemporary trends.

3. Visualizing your design

Bring your ideas to life through visualization. Outline key features such as insulation, waterproofing, and pocket placement. Sketch initial designs and produce digital renderings to see how the parka will look.

Ensure that the design fulfills all functional requirements for its intended use. This stage helps to refine the concept and make sure every detail is considered.

4. Perfecting the design

Transition from concept to detailed design. Develop comprehensive sketches and technical drawings that highlight proportions, features, and design elements.

Gather feedback from potential users or industry experts to refine the design. Whether adjusting the details yourself or with a designer, this step is crucial for achieving the best result.

5. Technical blueprint and materials

Create a detailed Tech Pack outlining specifications, materials, and measurements to minimize risks. Clearly defined requirements help streamline production. Also, sourcing high-quality materials ensures your final product meets the desired standards.

6. Final preparation and coordination

Coordinate with manufacturers to communicate design specifics clearly. Establish quality control measures to ensure the final product meets the highest standards.

Review prototypes thoroughly before moving to mass production. Discuss all aspects of the process, including steps and options, to ensure a smooth transition from design to finished parka.

Designing a parka is a meticulous process that blends creativity with practicality. By following these steps, designers can create parkas that not only meet market demands but also offer exceptional style and functionality.

Types of parkas

Designing a parka means more than picking out a few trendy fabrics—it involves choosing the perfect style for your needs. Parkas come in various forms, each crafted to meet specific requirements and preferences.

1. Classic parka

Source: MACKAGE

Embodying the essence of warmth, this parka features a long, insulated design perfect for extreme cold. Fur-lined hoods and multiple pockets enhance its practicality, making it ideal for harsh climates.

2. Puffer parka

Source: Moncler

The puffer parka stands out with its quilted, puffy appearance. Its insulated sections, filled with down or synthetic material, offer warmth without sacrificing mobility, perfect for casual wear or active adventures.

3. Hooded parka

Source: Stradivarius

Imagine a parka designed for snowy holidays—a hooded parka fits that description. Equipped with a fur-lined hood and and either down or synthetic insulation keep you cozy and stylish, even in the coldest conditions.

4. Duffle parka

Source: Macy’s

A shorter, a-line coat with toggle closures, the duffle parka makes a chic statement. Crafted from heavy wool or similar materials, it offers warmth and allows freedom of movement, making it a practical choice for casual settings.

5. Longline parka

Source: Phase Eight

Extending well below the hips, the longline parka delivers extra coverage against the cold. Whether fitted or relaxed, it’s a versatile choice for both urban and extreme environments.

6. 3/4 length parka

Source: Triple Fat Goose

Falling between the hip and knee, this parka blends coverage and mobility seamlessly. With a hood and adjustable cuffs, it adapts effortlessly to both city life and outdoor adventures.

7. Bomber parka

Source: Zavetti

Short and stylish, the bomber parka blends the classic bomber jacket’s charm with parka warmth. Ideal for urban environments and moderate temperatures, it offers a fashionable yet practical choice.

8. Fishtail parka

Source: Cockpit USA

Characterized by its distinctive fishtail hem, this parka offers both coverage and flexibility. Originally military wear, it’s now a favorite for casual outings, blending unique style with practicality.

9. Technical parka

Source: Rustan’s

Advanced materials give the technical parka superior protection against harsh weather. Prioritizing durability, outdoor enthusiasts often choose waterproof, breathable, and wind-resistant parkas for their high-performance features.

10. 3-in-1 parka

Source: Snowleader

Versatility defines the 3-in-1 parka, featuring a detachable liner and outer shell. Whether worn separately or together, it’s a versatile option for changing weather conditions.

Choosing the right type of parka hinges on its intended use and wearer. Each style offers unique benefits, so consider your needs and preferences carefully.

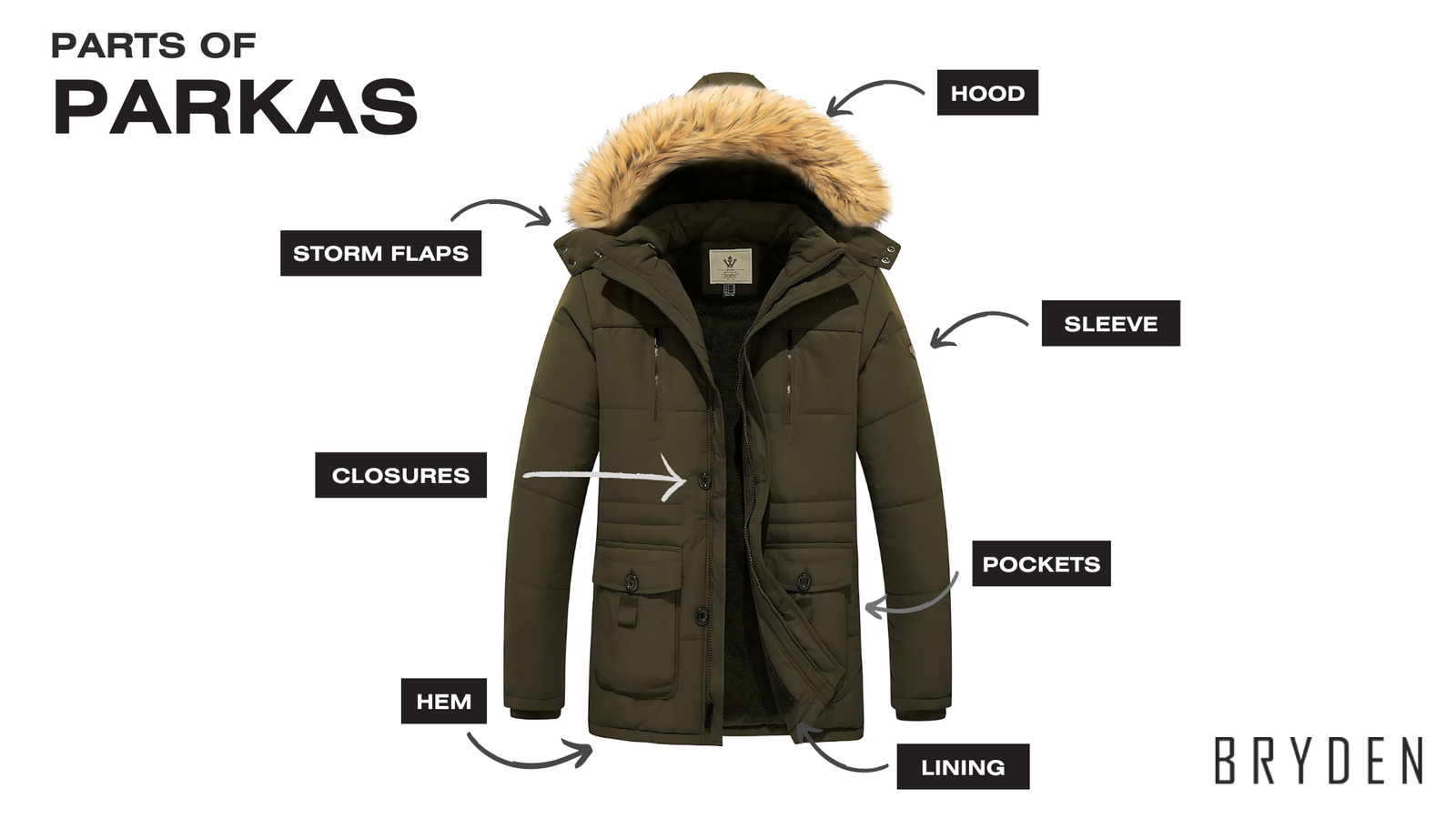

Anatomy of garment

Different styles call for varied components. Each component contributes to its overall functionality and style. Parkas come in various types, and their anatomy can vary significantly.

What are the parts of parkas?

Here are the essential parts of a parka, which are common across most styles:

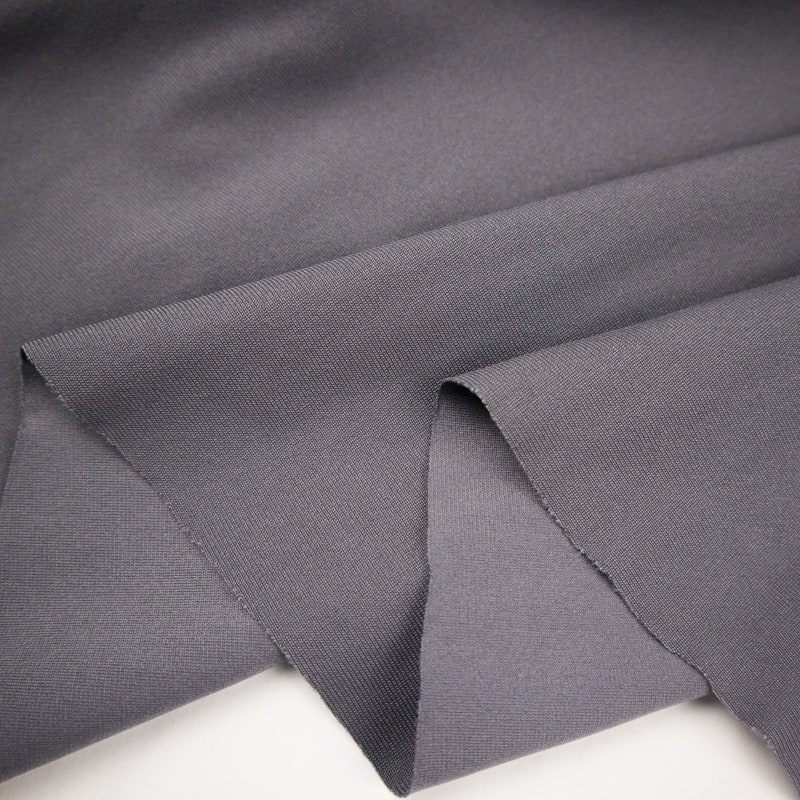

1. Shell

The shell forms the outer barrier of the parka. This layer shields against wind, rain, and snow. Key areas to consider include the center front, where closures like zippers or buttons are found, and the center back, which shields against the elements. Crafted from materials like nylon or polyester blends, the shell is essential for weather resistance.

2. Insulation

Think of insulation as your personal heat trap. Nestled inside the shell, it’s the layer that keeps you warm by capturing body heat. Whether it’s plush down feathers or advanced synthetic fibers, this internal layer is crucial for battling the chill.

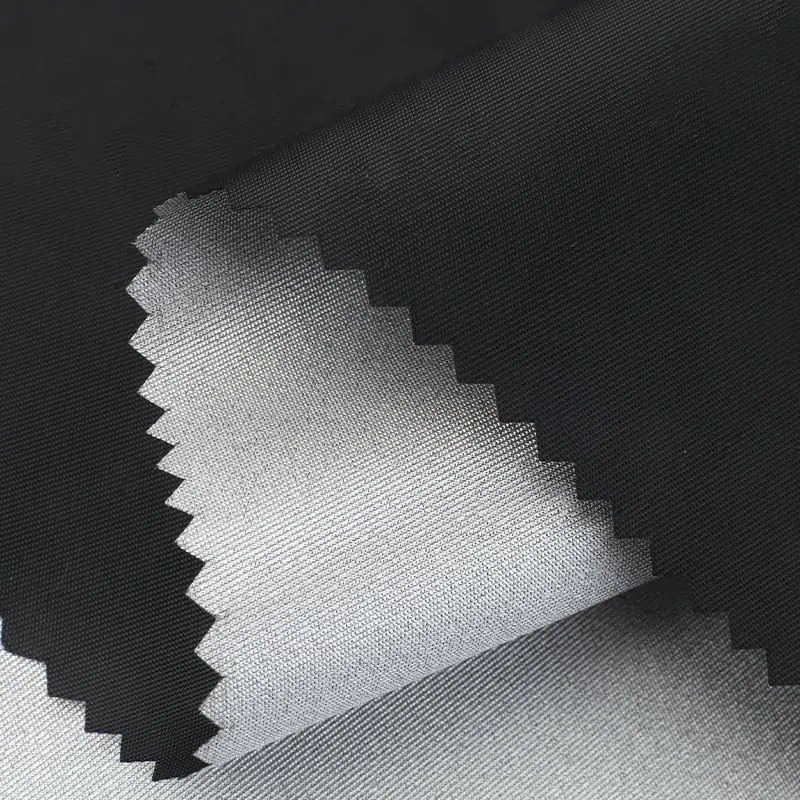

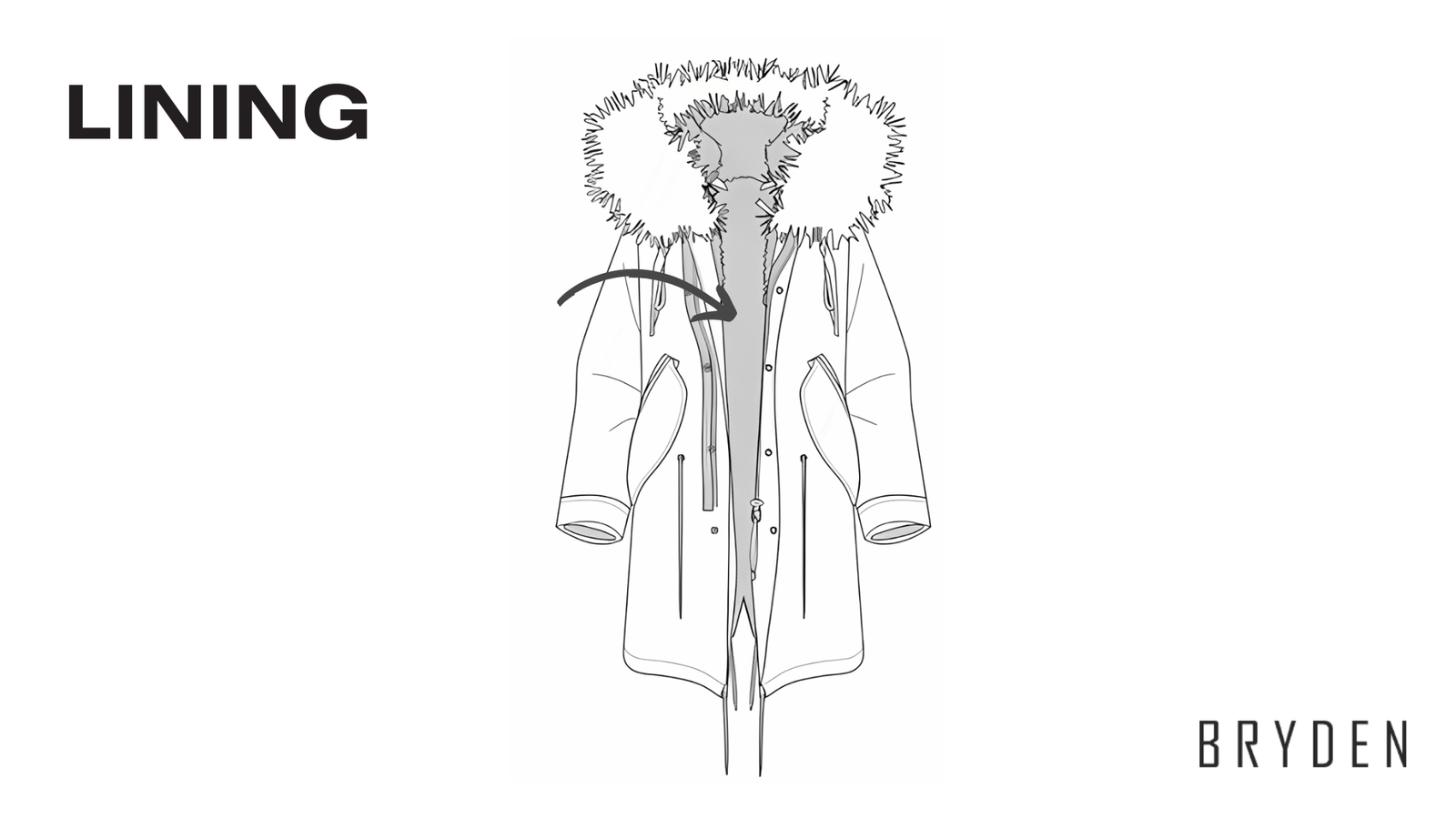

3. Lining

Directly in contact with your body, the lining adds comfort and, sometimes, extra warmth. It’s the inner fabric that feels soft against the skin, enhancing the parka’s overall comfort level.

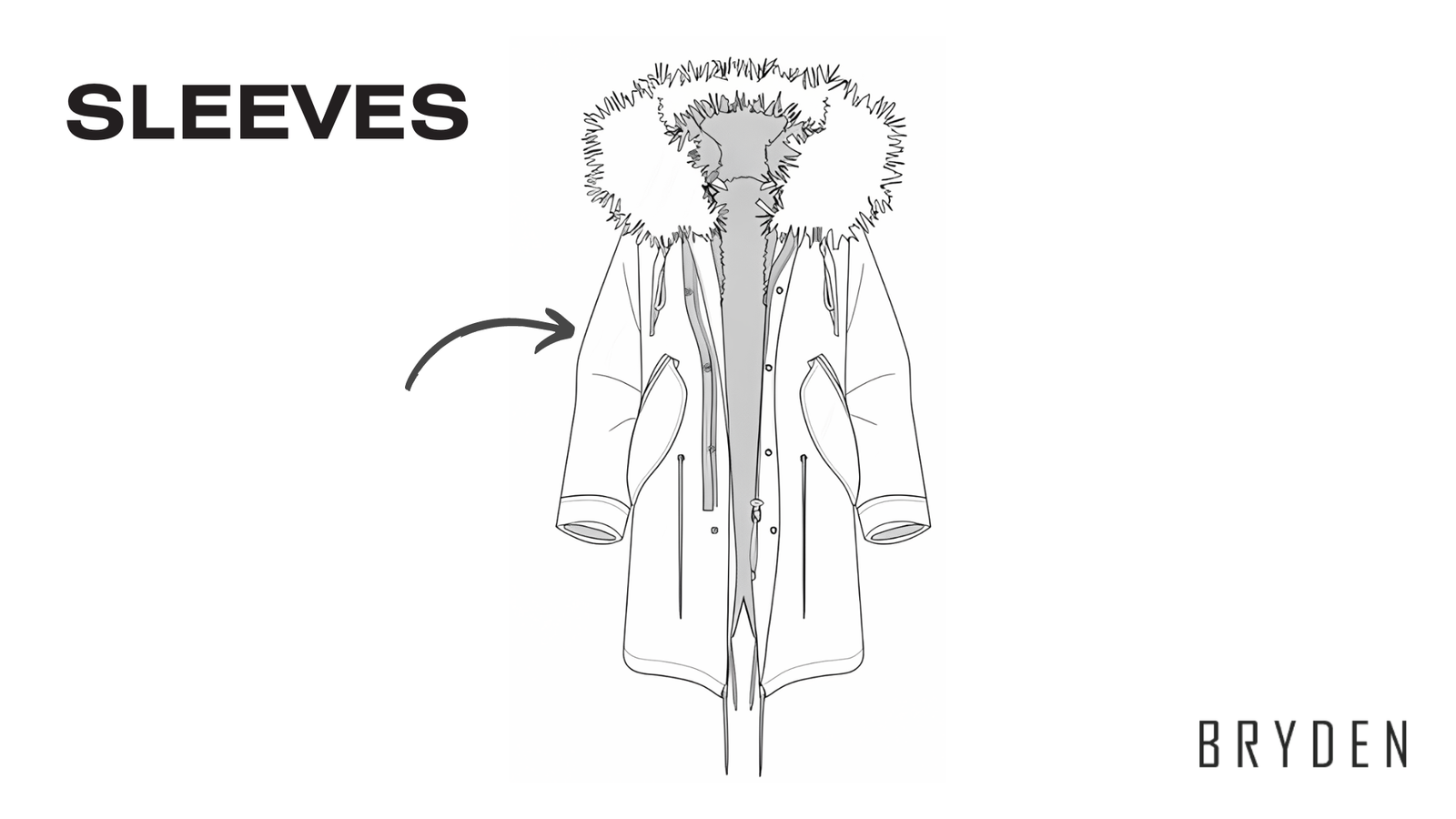

4. Sleeves

Covering your arms, the sleeves come in different segments: front, back, upper, and under. Each part contributes to the sleeve’s fit and function, ensuring full coverage and flexibility.

5. Pockets

Parkas often include various pockets—zippered, welt, or flap—for storing essentials and keeping hands warm in cold weather. They add practicality and a touch of style.

6. Hood

While not every parka includes a hood, those that do provide extra defense against the elements. Adjustable cords on many hoods allow for a tailored fit, enhancing both comfort and protection.

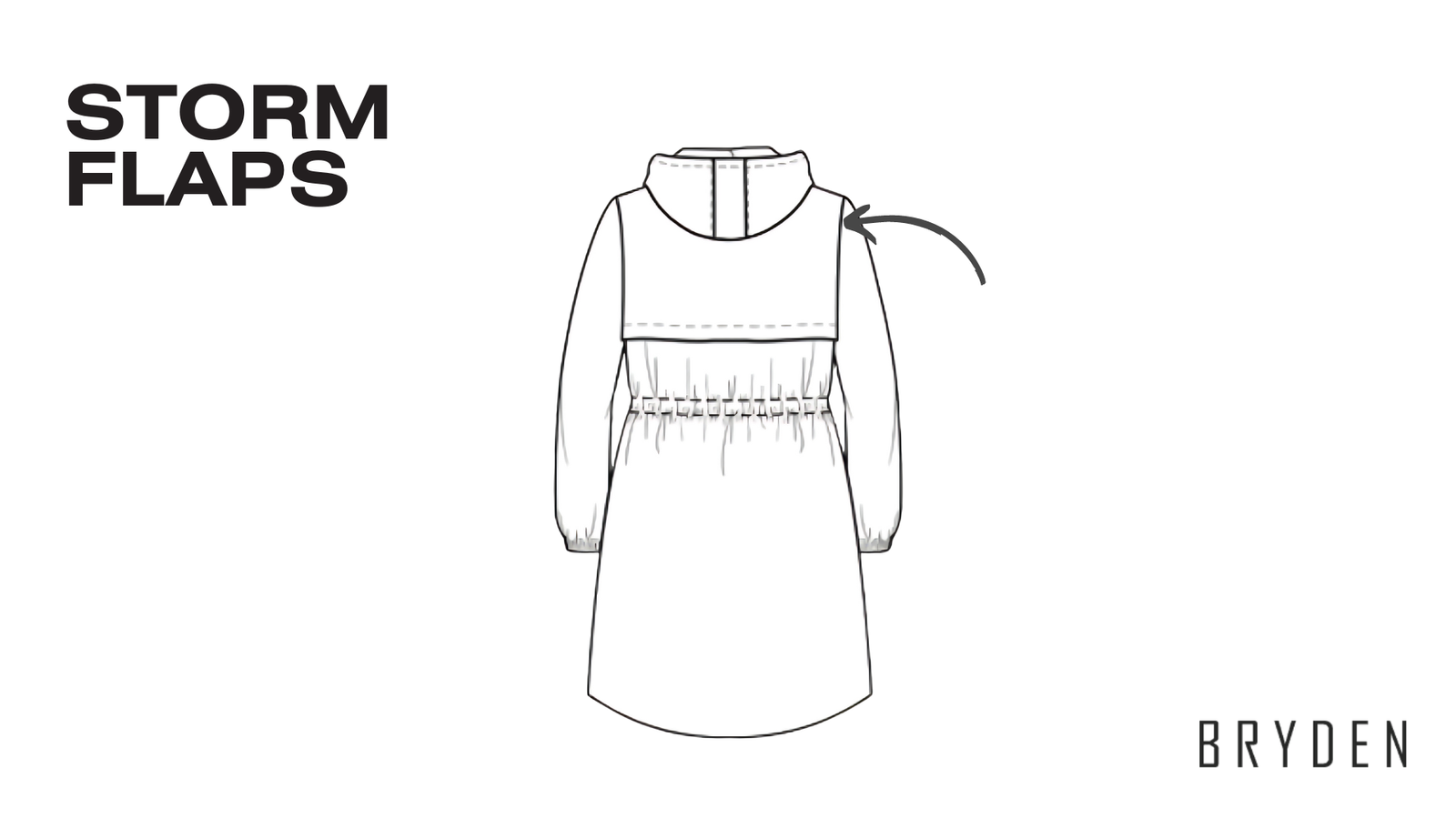

7. Storm flaps

Running over the zipper, storm flaps offer extra defense against wind and rain. These flaps aren’t present in every parka but are essential for those designed for harsher weather conditions.

8. Back vent

A slit or opening at the back of the parka, especially in longer styles, allows for better movement and ventilation. This feature is often found in parkas designed for active use.

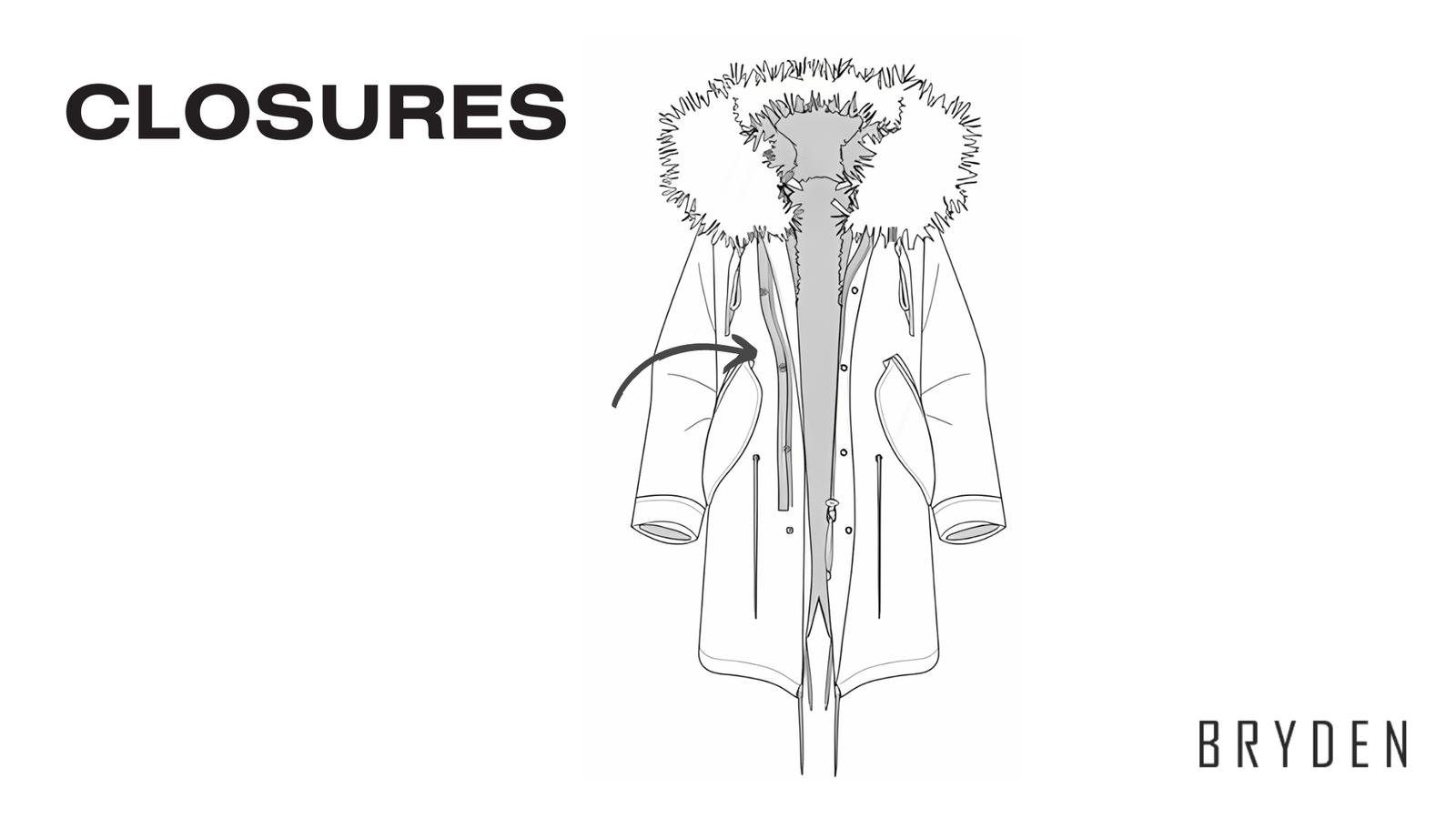

9. Closures

From zippers to buttons, closures are crucial for functionality. They run down the front of the parka, making it easy to put on and take off. Some parkas use toggles or snaps, depending on the design.

10. Hem

The hem, the bottom edge of the parka, often includes adjustable drawstrings. Designed to seal in warmth and block out cold air, closures add to the parka’s insulating qualities.

Beyond the basics, some parkas feature additional elements like drawstrings or reinforced cuffs, offering extra functionality and comfort. Each element ensures the parka meets various needs, whether for extreme cold or everyday wear.

Choosing quality fabrics

Selecting the perfect fabric for parkas can make all the difference in performance and style. Here’s a quick guide to some top fabrics used in parkas:

1. Wool and wool blends

Wool is a go-to for classic warmth and durability. Wool blends, mixing in synthetics, enhance durability and ease of care. Expect great insulation with added resilience!

2. Cotton and cotton blends

Cotton’s breathable nature keeps you comfortable in various temperatures. Cotton blends add stretch and durability, perfect for versatile parkas that need a bit of flexibility.

3. Fur and faux fur

Looking for luxury? Real or faux fur adds a plush touch. Faux fur is an ethical choice and more budget-friendly. Use it for hoods or trims to elevate your parka’s style.

4. Polyester

Durability meets practicality with polyester. Often chosen for both outer shells and insulation, synthetic fibers are lightweight and quick-drying, making them ideal for weather-resistant parkas. A staple in many winter designs.

5. Nylon

Need to fend off the elements? Nylon, both durable and water-resistant, acts as a solid outer layer. Blending well with other fabrics, it offers reliable weather protection.

6. Fleece

Fleece, soft and breathable, excels as an insulator. Lightweight and easy to care for, it provides warmth without bulk.

7. Cashmere

Craving luxury? Cashmere, known for exceptional softness, offers unparalleled warmth. This lightweight fabric elevates any high-end parka.

8. Technical fabrics

Planning for specialized features? Technical fabrics like Gore-Tex and Kevlar provide unmatched protection. Waterproof, breathable, and durable, these materials thrive in extreme conditions.

Choosing a parka means balancing warmth, durability, and style. Fabric selection determines how well your design performs and looks.

Pattern making and cutting

Creating a pattern for a parka involves several crucial factors. This blueprint dictates the shapes and dimensions of every component, from body panels to sleeves and hoods.

-

Fit and size variability

A thoughtfully designed pattern balances layering space with a flattering fit. Men’s and women’s patterns differ, considering variations in shoulder width, waist shaping, and sleeve length to ensure the best fit.

-

Functional design elements

Patterns must also plan for practical features such as hoods, storm flaps, and elastic cuffs. These elements enhance both the look and functionality of the parka, providing protection against wind and cold.

-

Material behavior

The choice of fabric influences how the pattern is shaped. For example, the thickness of insulation and the drape of the outer shell must be accounted for in the pattern to ensure proper fit and functionality.

-

Proportion and balance

Balancing proportions is essential in pattern design. Length, hood size, and pocket placement all need to harmonize. During the prototyping stage, designers often adjust these elements to achieve a cohesive look and comfortable fit.

-

Cutting the pattern

Once the pattern is finalized, cutting the fabric accurately is vital. Precise cuts ensure that every piece fits together perfectly, affecting the final product’s overall quality.

Attention to these details during pattern making and cutting can significantly impact the finished parka. Each step in this phase contributes to creating a high-quality garment ready for any adventure.

Pattern making (how to with samples)

Building on the crucial factors from the previous section, let’s dive into pattern making—where creativity meets technical skill. The perfect parka pattern involves addressing various challenges and incorporating numerous features to ensure both style and functionality.

-

Balancing design and function

Designing a parka that is both stylish and functional requires careful attention. Patterns must integrate aesthetic elements without sacrificing practical aspects, like warmth and protection.

-

Complexity of features

Incorporating features such as multiple pockets, hoods, and drawstrings adds complexity. Each detail must be accurately included in the pattern to ensure it functions as intended.

-

Durability considerations

Parkas face harsh weather conditions, so patterns must account for durability. Reinforced seams, storm flaps, and other protective elements need to be factored into the design.

-

Communication with manufacturers

While these challenges are part of the pattern-making process, effective communication with manufacturers helps in developing a well-made pattern. This ensures that the final product aligns with both design and functional requirements.

To illustrate the variety of patterns, here are some sample parkas:

1. The classic parka

This classic design features a straight silhouette with a drawstring at the waist, a longer back cut, flap pockets with press studs, and a hood with dividing seams. The classic elements ensure practicality while maintaining timeless appeal.

2. A chic parka

Source: Etsy

This pattern showcases a stylish design with unique features. It includes yokes on the front and back, zippered welt chest pockets, shaped welt slash pockets, and a detachable hood. The extended shoulder line and relaxed fit of the sleeves add to its modern aesthetic. Detailed patterns like this require careful planning to manage all the intricate features.

These samples illustrate how different features and design choices influence the pattern. Each pattern serves as a guide, ensuring that the final parka meets both aesthetic and functional needs.

Marking tips for cutting patterns on fabric

Accurate marking is vital for cutting patterns, ensuring each piece aligns perfectly during assembly. Here’s how we approach this critical step:

-

Picking the perfect marking tool

We choose tools like tailor’s chalk or washable pens that mark clearly without harming the fabric. Each tool leaves distinct marks, tailored to the fabric type.

-

Nailing key points

Critical areas—like notches and seam lines—get marked with precision. These marks are our roadmap, guiding every step of the sewing process to keep the garment’s structure intact.

-

Staying consistent

Consistency is key. We use solid lines for seams, dashed for folds, and dots for notches, keeping everything clear and confusion-free.

-

Double-checking placement

Before marking, we make sure the pattern pieces are perfectly placed, considering grainlines and seam allowances. A quick check prevents fabric waste and costly mistakes.

-

Locking down the pattern

To prevent shifting, we secure the pattern with pins or weights. This keeps everything in place, leading to flawless cuts.

These steps ensure that every mark leads to a perfectly aligned, high-quality parka.

Cutting and sewing in parka manufacturing

After patternmaking, the fabric begins its transformation into a parka through cutting and sewing. Here’s an overview of this process:

-

Preparation and marking

Before any cutting begins, the fabric is laid out and thoroughly inspected for flaws. Key features like pockets, zippers, and seams are marked with precision, guiding the assembly and ensuring proper alignment.

-

Pattern placement

The pattern pieces are strategically placed on the fabric to minimize waste and ensure efficiency. This careful placement is crucial for making the most out of the material.

-

Sequential assembly

Once all pieces are cut, the sewing process starts, bringing the parka to life. It typically begins with simpler elements like pockets, then progresses to more complex constructions like the body and hood. Each step is executed with care to ensure durability and functionality.

-

Seam construction

Various seam types are employed depending on the design and fabric properties. The right seams are essential to maintain the integrity of the parka under different conditions.

-

Reinforcement

Areas like pockets, zippers, and hoods often receive extra reinforcement through additional stitching or binding tape, preventing unraveling and adding strength.

-

Fastener installation

Zippers, snaps, and buttons are installed with precision, using special stitching techniques to ensure they operate smoothly and align perfectly.

-

Cuff and hem finishing

The final touches include finishing the cuffs and hems, which may involve elastic bands, adjustable tabs, or other features to ensure a snug fit and protection against wind and cold. The chosen finishing technique depends on the overall design and intended use of the parka.

How to cut the parka

Cutting the fabric is as crucial as the pattern-making process, setting the stage for the final product. Manufacturers ensure each step is handled with care to maintain the integrity of the design. Here’s what they focus on:

-

Efficient layout

The layout of pattern pieces on the fabric is planned to minimize waste. This is especially critical when dealing with high-cost or specialized materials. Every inch counts to keep costs down without compromising quality.

-

Precision cutting

Accuracy is paramount. Even the slightest error can cause fit or assembly issues. While manual cutting might be used for smaller batches or delicate fabrics, automated cutting tools are often preferred in mass production to ensure consistent precision.

-

Layered cutting

For parkas with multiple layers, each material—whether it’s the outer shell, insulation, or lining—is cut separately. This ensures proper alignment across the garment, which is vital for both performance and appearance.

Achieving top-notch results often involves manufacturers blending cutting techniques—die cutting, laser cutting, and automated machines. Precision isn’t optional; it’s crucial for crafting a high-quality parka.

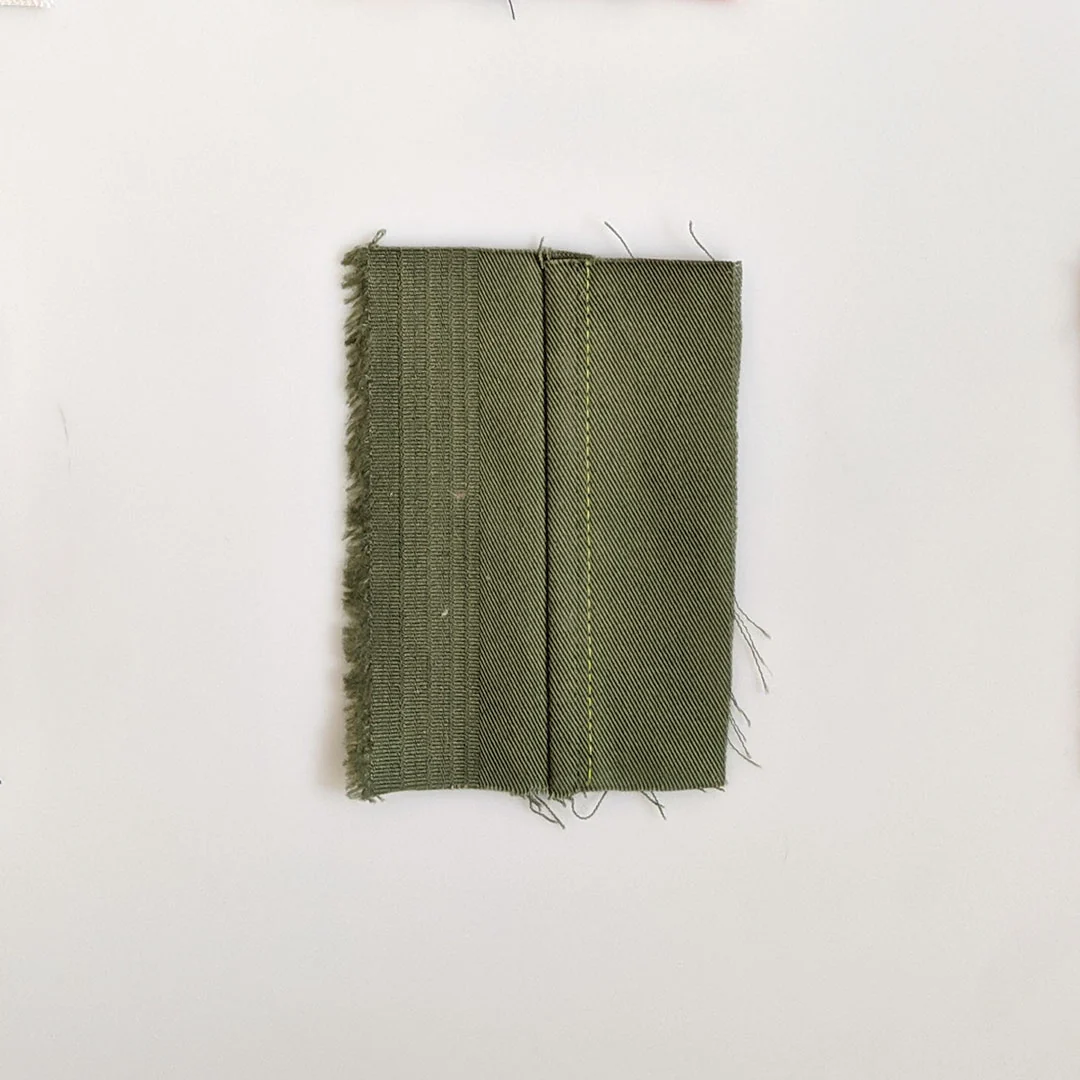

Different types of seams for parkas

Seams hold the fabric together, shaping every aspect of the parka from the hood to the hem. These stitches aren’t just about holding things in place—they also influence the parka’s strength, appearance, and comfort.

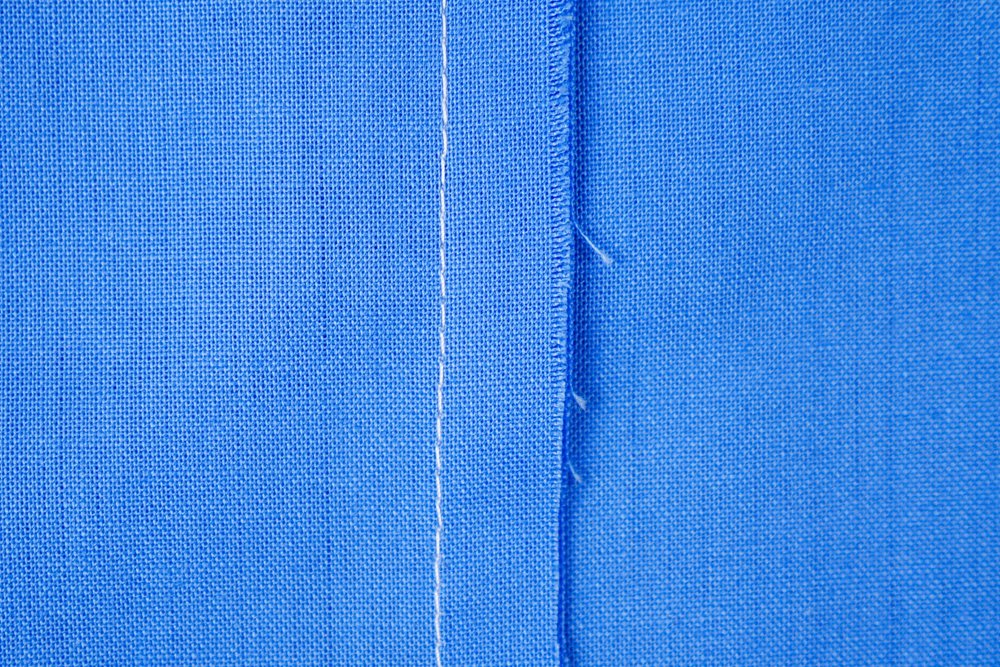

1. Plain seam

Source: Echidna Sewing

Simple yet effective, this seam involves stitching two fabric pieces with the right sides facing. Ideal for most areas, it offers versatility without fuss.

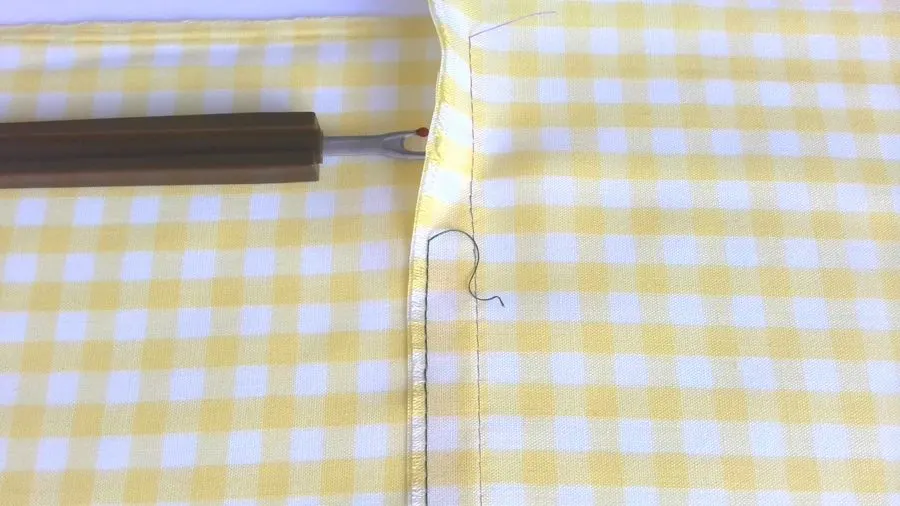

2. Bias bound seam

Source: Treasurie

Enclosing raw edges with a binding, this seam adds a polished finish while keeping fraying at bay. It’s a practical choice when you want a neat edge with a bit of flair.

3. Hong Kong seam

Source: Adopt Your Clothes

A refined option where bias tape wraps the raw edges, leaving them visible inside the parka. Perfect for unlined designs, it adds a touch of sophistication.

4. Flat-Felled seam

Source: Grainline Studio

Built for durability, this seam folds raw edges under, stitching them flat. Often seen in heavier garments, it’s a go-to for areas needing extra reinforcement.

5. Lapped seam

Source: Ageberry

One piece of fabric overlaps another, secured with topstitching. This technique not only strengthens the seam but also introduces a decorative element.

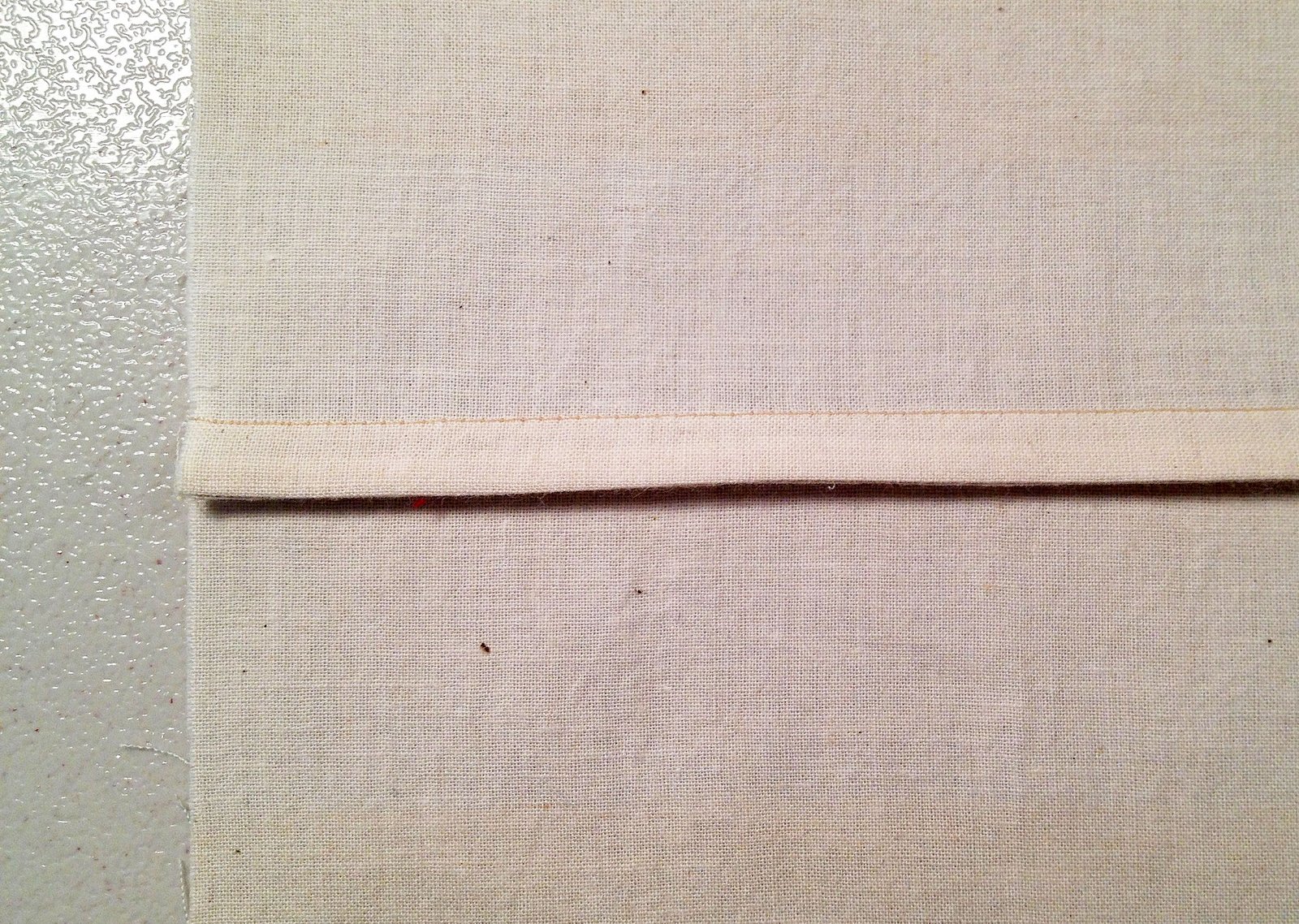

6. French seam

Source: Yesterday’s Thimble

Raw edges are tucked within the seam, offering a clean, durable finish. Ideal for lightweight fabrics, it ensures the inside of the parka looks as good as the outside.

Different seam types contribute unique strengths to the design. These elements enhance the parka’s durability, style, and functionality.

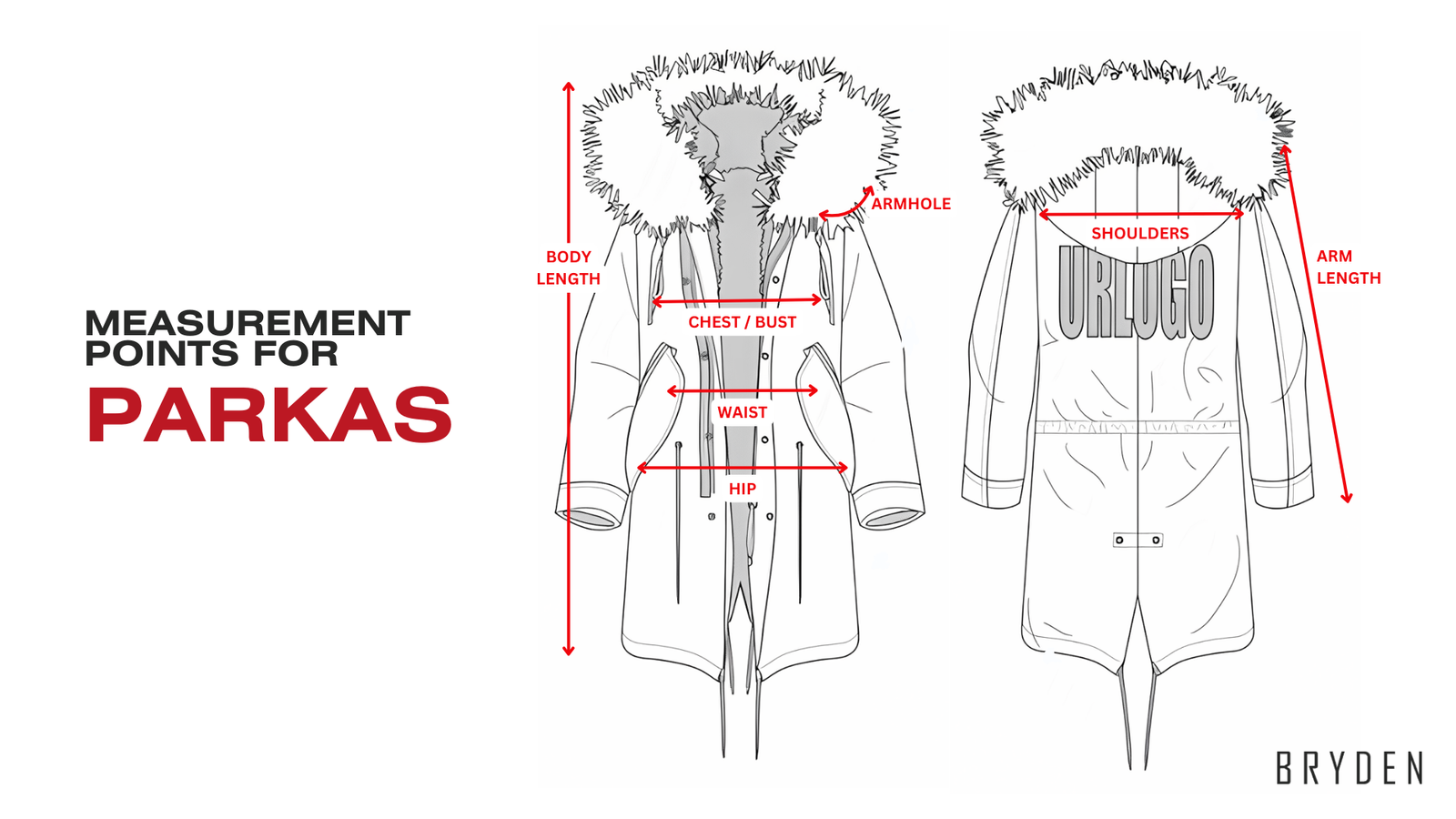

Measurement points for parkas

When it comes to crafting a parka, precision in measurements is key. The fit, comfort, and overall silhouette of the final product all hinge on getting these details right.

1. Chest

Measuring around the fullest part shapes how the parka sits on the body, offering room for layering and ensuring a flattering fit.

2. Waist

A well-measured waist keeps the parka sleek and functional, whether adjustable with drawstrings or a belt, enhancing both style and warmth.

3. Hip

A parka needs to move with you—measuring around the fullest part of the hips ensures comfort and a secure, stylish fit.

4. Shoulder width

The parka’s shoulders can make or break its fit. Measuring from shoulder seam to seam ensures the parka stays perfectly in place.

5. Sleeve length

Measuring sleeve length demands accuracy—too short, and warmth is lost; too long, and it becomes unwieldy. Start from the shoulder seam and measure to the wrist for a perfect fit.

6. Body length

From cropped to knee-length, the body length defines the parka’s function. Measure from the highest point to the hem for the right silhouette.

7. Hood dimensions

Hood size and depth matter, more than many realize. Ensuring the hood’s length, width, and depth are just right provides a snug, protective fit.

Each measurement significantly influences the parka’s construction, transforming it into a garment that not only looks great but also excels in harsh conditions.

The art of printing

Printing on parkas blends artistry with functionality—it’s not just about looks; durability and impact are key. Here’s a glimpse into popular printing techniques used in parka manufacturing, along with some insider tips to guide your choices.

Common printing techniques used for parkas

1. Screen printing

Source: Local Deadbeat Agency

Bold, vibrant, and perfect for making logos pop, screen printing uses stencils to layer ink onto fabric. It’s a favorite for outdoor brands wanting their designs to stand out, especially on parkas built for adventure.

2. Reflective printing

Source: The North Face

When visibility is key, reflective printing comes into play. This technique adds reflective materials to the fabric, making sure the wearer is seen even in low light. You’ll often find it subtly woven into the design—around the hood, across the chest, or edging the parka.

3. Heat transfer printing

Source: Essential Workwear

For intricate, multicolored designs, heat transfer printing is the go-to. Designs are first printed on special paper and then transferred to the fabric using heat and pressure. It’s common in custom parkas where personalized names or team logos need to shine.

4. Foil printing

Source: John Lewis & Partners

Foil printing catches the eye with its metallic sheen, applying a layer of reflective foil to the fabric. Popular in urban and streetwear, it adds a flashy edge to functional designs.

5. Digital printing

Source: Meet

When detail matters, digital printing steps up. It allows for complex designs to be printed directly onto the fabric, ideal for small production runs where every detail counts.

6. All-over print

Source: Notorious Tribe

For those looking to make a statement, all-over print covers the entire fabric surface before it’s cut and sewn. Sublimation is often used here, creating vibrant, full-coverage designs that turn heads.

Choosing the right printing technique depends on the design, fabric, and scale. A conversation with your parka manufacturer will help you navigate the options and find the perfect fit for your vision.

Different types of garment washing for parkas

Washing techniques transform parkas in various ways, giving them distinctive looks and feels. Here’s a peek behind the curtain at how these washing processes bring out the best in parkas:

1. Garment wash

Source: Pahis.fi

A straightforward process, garment washing softens fabric, creating that comfy, lived-in vibe right from the start. Water and mild detergents do the trick, making parkas feel cozy and ready to wear—think everyday casual pieces with an immediate touch of comfort.

2. Enzyme wash

Source: Atom Retro

By employing enzymes to gently break down fabric cellulose, this method achieves a smooth, soft finish with minimal pilling. Eco-friendly and gentle, enzyme washing produces high-quality parkas with a velvety touch that feels luxurious without being harsh on the environment.

3. Destroy wash

Source: PLNDR

For those who crave a bold, distressed look, destroy washing fits the bill. Abrasive materials or chemicals are used to create a rugged, vintage feel, perfect for fashion-forward parkas that make a statement. This technique is all about embracing that worn-out aesthetic.

4. Stone wash

Source: DSQUARED2

Adding a unique texture, stone washing involves pumice stones that rub against the fabric, resulting in a faded, worn-in appearance. Ideal for casual parkas, this method imparts a vintage charm that is often associated with heritage brands and their classic styles.

5. Bleach wash

Source: Lane Crawford

Want to create a striking, bleached effect? Bleach washing does just that by lightening fabric colors and crafting eye-catching patterns. This bold approach is perfect for parkas looking to stand out in fashion collections with a daring, washed-out look.

6. Pigment wash

Source: Endource

Infusing pigments into the wash process gives parkas a soft, muted color with a unique, faded look. Ideal for those who appreciate a vintage aesthetic, pigment washing adds a distinct touch to casual and outdoor wear, blending style with a hint of nostalgia.

These washing techniques not only alter the look and feel of parkas but also cater to diverse styles and preferences. If you’re curious about more details or available options, your manufacturer can provide insights tailored to your specific needs.

Fabric dyeing technique for parkas

Dyeing parkas isn’t just about adding color—it’s about enhancing both their look and functionality. Each technique imparts a unique character, transforming fabrics to meet various style needs. Here’s how different dyeing methods can bring out the best in your parkas:

Resist dyeing techniques

Resist dyeing involves techniques where certain parts of the fabric are protected from the dye, creating striking patterns. This method can elevate a parka’s style, offering a unique visual appeal.

-

Tie-dye

Source: Zalora

Fabric is twisted and bound before dyeing, resulting in vibrant, psychedelic designs. Perfect for casual parkas, tie-dye adds a splash of color and a burst of individuality.

-

Ice dye

Source: KICKS CREW

By placing ice on fabric and sprinkling dye over it, ice dyeing creates mesmerizing, watercolor-like patterns as the ice melts. Ideal for fashion-forward parkas seeking a distinct, blended color effect.

-

Marbling

Source: Philipp Plein

Floating colors on water and transferring them to the fabric produces fluid, abstract patterns. This method imparts a parka with a rich, artistic flair, turning it into a piece of wearable art.

Gradient and layered dyeing techniques

These techniques involve applying dye in layers or gradients to achieve depth and movement in color.

-

Ombre dip dye

Source: Rent the Runway

Dipping fabric into dye gradually creates a seamless gradient effect. Parkas with this technique showcase a sophisticated color transition, adding a modern touch.

-

Overdye

Source: Urban Outfitters

Applying a new dye over an existing color creates unique shades and textures. Overdyed parkas boast rich, layered colors, perfect for adding depth to your wardrobe.

Chemical reaction techniques

Chemical reactions during dyeing result in vibrant, long-lasting colors that make a statement.

-

Reactive dye

Source: KommandoStore

These dyes form a permanent bond with the fabric, resulting in bright, durable colors that resist fading. Reactive dyeing ensures parkas remain vibrant and eye-catching over time.

-

Cross dye

Source: Canada Goose Generations

This method involves using two different dyes on fibers that react differently, creating a multi-tonal effect. Parkas dyed this way feature a distinctive, stylish appearance that stands out.

Quality control measures

In the world of parka manufacturing, quality control isn’t just a procedure—it’s our passion. Here’s how we ensure every parka stands out:

-

Raw material inspection

Before sewing begins, we meticulously examine every fabric, zipper, and snap. We catch imperfections early, from color inconsistencies to hardware flaws, ensuring nothing disrupts the final product’s quality.

-

Accurate sizing and fitting

Sizing is an art. We use precise charts tailored to various needs, from outdoor adventurers to urban explorers. Our size guides help find the perfect fit, whether it’s a roomy parka for layering or a snug fit for everyday wear.

-

Functional testing

Parkas must perform. We test waterproof features, checking seams and zippers for leaks and verifying insulation warmth. Every parka is rigorously assessed to ensure it’s up to any weather challenge.

-

Final inspection

The last step is all about perfection. We inspect for visible defects, test every fastener, and ensure all labels and logos are spot-on. Each parka is carefully checked to meet our high standards before it reaches you.

From start to finish, our quality control measures guarantee that each parka is crafted to excel—ready for anything and designed to impress.

Packaging and branding

A parka’s journey doesn’t conclude with production; presentation and promotion finalize the process. Effective packaging and branding go beyond protection, aiming to leave a lasting impression.

-

Wrapping up in style

More than mere protection, parka packaging sets the stage for a memorable first impression. Sturdy, moisture-resistant materials keep the garment pristine during transit. Custom designs typically reflect a brand’s unique identity, while eco-friendly options highlight a dedication to sustainability.

Patagonia stands out by incorporating recycled materials and minimalist designs, demonstrating a strong commitment to environmental responsibility. Their packaging communicates their brand values, reinforcing a strong environmental message.

-

Branding with a bang

Branding goes beyond logos—it’s about telling a story. Quality labels, unique design elements, and custom hangtags highlight the parka’s features and values. Consistent branding on both the garment and its packaging solidifies a brand’s image.

Source: Switchback Travel

Arc’teryx blends technical innovation with sleek design, using their branding to highlight performance and sustainability. Their strong global presence and unwavering standards help them stand out in a competitive outdoor market.

Packaging and branding shape a parka’s final impact. Beyond just delivering a product, they ensure it arrives as part of a well-rounded, impressive experience.

Conclusion

Finding the right custom parka manufacturer involves exploring the diverse range of techniques and quality measures discussed here. From innovative dyeing methods to meticulous quality control, knowing what goes into each step helps you make an informed choice.

Ready to bring your parka ideas to life? Reach out for expert guidance and turn your ideas into standout parkas that impress and perform.